You have found the correct recipe which produces fluffy biscuits...

Read MoreBiscuit Production Machine: A Complete FAQ Guide

The process of making biscuits has changed a lot over time, owing to the changes in technology and the mechanization of operations. Currently, biscuit production machines have transformed this process to a whole new level as manufacturers embrace precision and efficiency, which has shifted the focus from manual operation. If you have experience in biscuit production or are new to the business, you need to know the functioning of these tools and other aspects for better production and quality management. These FAQs answer the most popular questions related to biscuit production machines. Proper maintenance is vital to prolong the service life of the machine and guarantee the quality of the final product. This guide will cover every aspect of such questions and many more regarding biscuit production machines. By the time you finish reading this book, you will already know what tasks these machines can perform in the bakery and whether or not their use can benefit your production line.

Introduction to Biscuit Production

Manufacturing biscuits is an organized activity for creating goods through the amalgamation of tools and raw materials in specific proportions. This activity begins with the mixing of other basic materials, that is, flour, sugar, fats or their substitutes, shaping the dough, controlled baking and cooling, and finally packaging. Nowadays, to produce biscuits, a totally integrated biscuit production machine is used in order to assure conformity, most especially in meeting market needs for small and large-scale production. The spare parts for biscuit-forming equipment allow for the enhancement of production without compromising product quality and hygiene.

What Are Biscuit Production Machines?

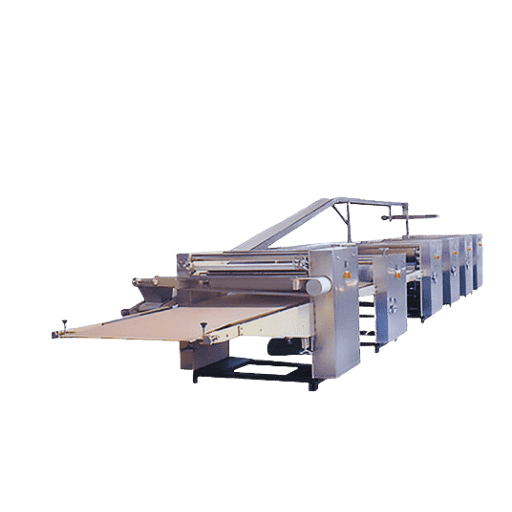

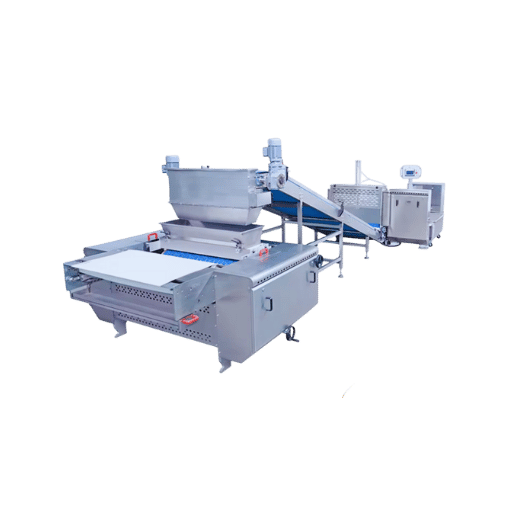

Biscuit production machines are engineered tools designed to ensure that the making of biscuits is easy and efficient. These machines perform different tasks and stages of production, including mixing of ingredients, kneading of the dough to the required shape, baking, cooling, and packing. They are designed to aid in the processes and make sure they are effectively executed and meet the hygienic as well as quality requirements. Some of the most common biscuit production machine types are mixers, rotary molders, ovens, and cooling conveyors, each having a function in the production process. The use of these machines has dominated the biscuit manufacturing process and has allowed biscuit production on a large scale that meets customer needs.

Overview of Biscuit-Making Process

Typically, five important stages exist in biscuit preparation:

- Mixing – Ingredients are thoroughly mixed to give the dough a uniform consistency, texture, and flavor.

- Shaping – Shaping of the dough into biscuits is done by one of several processes, such as rotary molding or stamping.

- Baking – The shaped dough is baked at controlled temperatures so as to develop the right texture and color.

- Cooling – Every baked biscuit shall be cooled to ambient temperature, thus preventing moisture retention and preserving quality in industrial biscuit production.

- Packaging – Biscuits are packaged in materials suitable for maintaining freshness to further develop shelf life.

These steps ensure efficiency, product quality, and food-safety standards.

Types of Biscuit Production Machines

🔧 Dough Mixers

Dough mixers are used to bring together ingredients in uniform dough, giving way to consistency in texture and quality.

⚙️ Rotary Molding Machines

These are biscuit-shaping machines that press dough into molds that contain certain engraving patterns.

✂️ Wire-Cut Machines

The machine is used for cutting soft dough into certain sizes or shapes. After which, the dough is then baked. They help assure constant biscuit sizes.

🔥 Tunnel Ovens

The kind of heat flow that ensures even baking throughout the biscuit is provided by tunnel ovens.

❄️ Cooling Conveyors

During the cooling process, the conveyor transports under certain conditions to prevent damage to the biscuit.

Choosing the Right Biscuit-Making Machine

Key Features to Consider When Buying a Biscuit-Making Machine

- Production Capacity– Ensure the machine can comfortably handle higher output volumes for your business demand. Buying biscuit making equipment depends on this.

- Flexibility and Versatility– Look for that equipment that can give you different biscuit types and shapes for product variation.

- Ease of Operation– Give preference to the machine that has a user-friendly interface requiring minimal training to facilitate smooth operations.

- Material Durability and Build Quality– Opt for the machine built from high-quality materials; hence, the machine should be able to last and function efficiently, especially when subjected to heavy use.

- Maintenance and Support– Hand in hand with maintenance should be technical support. It should be very easy to maintain, which in turn reduces downtime and keeps production flowing.

Types of Biscuit Machines: Automatic vs. Manual

The classification presents biscuit machines into manual, semi-automatic, and fully automatic types. Each secondary categorization offers significantly different automation levels, efficiency, and scalability.

| Key Point | Manual | Semi-Automatic | Automatic |

|---|---|---|---|

| Automation | None | Partial | Full |

| Efficiency | Low | Moderate | High |

| Labor Need | High | Medium | Low |

| Cost | Low | Moderate | High |

| Output | Low | Medium | High |

| Flexibility | High | Moderate | Low |

| Hygiene | Basic | Improved | Advanced |

| Maintenance | Simple | Moderate | Complex |

| Scalability | Limited | Moderate | High |

| Suitability | Small-scale | SMEs | Large-scale |

Capacity and Production Speed Needs

To determine the minimum and maximum output capacities of a machine and the speed of production needed, it is important as well to equal the output of the machine to industrial requirements. For example, machines with output as low as 10-100 kg/hour or even less can suffice if it is a small factory or a handmade production. In fish or meat plants where the production volumes are high, the use of a machine that has an output in excess of 500 kg/h should be employed. Look at the speeds of production, consider levels that suit the required operations and particular demand and use, and buy machines that have the advantage of being able to work with different batch sizes.

Benefits of Using Automatic Biscuit Making Machines

Consistency and Efficiency in Biscuit Production

Every automatic biscuit production machine offers the assurance of good quality and evenness of all biscuits produced. However, these machines do not perform monotonous work mechanically; they are very accurate and capable of minimizing human errors and morphological differences. With these machine workers, the time of production is curtailed, and the work is accomplished quickly, even in tight schedules. Furthermore, they enhance productivity at a faster rate with the same level of finished goods due to their dependability and speed.

Scalability for Large-Scale Operations

Biscuit production is efficiently scaled through the implementation of automation. This means they can handle more production without contamination or lowering performance. Modular designs and brands that are flexible enable automated machines to stretch limits without causing idle times. This is to ensure that every company operates efficiently by producing enough, reducing employment costs, and improving operations.

Quality Standards in Biscuit Manufacturing

Quality standards in biscuit manufacturing are there to put forth the final guarantee, ensuring consistent taste, texture, safety, and appearance. The aspects are:

- Higher-grade raw material and precise formulations are used.

- Maintaining strict control of temperature and humidity during processing.

- Regular inspections and testing occur at every stage, from ingredient supply to packaging.

- An evident key component of good biscuit production is adherence to all recognized food safety standards, such as HACCP (Hazard Analysis and Critical Control Points), to avoid contamination or disparity in producing the product.

All these acts serve to guarantee a quality product to be consumed in the hands of the client.

Types of Biscuits and Their Production

Common Types of Biscuits

🍪 Digestive Biscuits

Wholemeal biscuit is known for its mildly sweet taste, high fiber, and is eaten as a snack and sometimes with tea.

🧈 Shortbread Biscuits

Having a buttery richness, the biscuits get their crumbly texture from the simple combination of flour, sugar, and butter.

🥛 Cream-Filled Biscuits

The two layers of biscuit are supposed to be filled with sweet cream flavored with vanilla, chocolate, or strawberry.

🌾 Oat Biscuits

With oats as a main ingredient, these biscuits tend to have a more chewy texture. They are often chewy synergy for nutritional good points.

🍫 Chocolate-Covered Biscuits

Coated with some chocolate of traditional or shortbread variety, for greater indulgence.

🧀 Savory Biscuits

With herbs, spices, or cheese incorporated into these biscuits, they make for an interesting choice for a savory snack or accompaniment to soups and salads.

Specialized Machines for Different Biscuit Types

The production of different biscuit types requires machinery specially designed for their respective peculiarities and production processes. Some examples of such machinery can be listed:

- Rotary Molding Machines – Such machines are designed for soft dough biscuits like shortbread and digestive; soft dough biscuits require delicate handling in order to retain their shapes and sizes, a real job for rotary molding machines.

- Wire-Cut Machines – For soft, sticky dough, wire-cut machines work beautifully to provide design and output uniformity.

- Oven Systems – Tunnel ovens are most popular; they treat baking conditions in controlled atmosphere, suitable partly for savory biscuits and partly for chocolate-coated varieties.

- Enrobing Machines – For coating with chocolate, enrobing machines provide excellent, even coating or dipping for our biscuits.

- Laminators – For flaky and layered dough chiffon bisquing, the laminator offers the final steps of sheeting and layering.

All these machines bring efficiency into production as well as manufacture quality across the different types of biscuits.

Continuous Production vs. Batch Production

🔄 Continuous Production

This uninterrupted manufacturing process assures output consistency and maximum efficiency. This method is supported by massive production and uniform quality, such as for standard-style biscuits.

📦 Batch Production

This makes the products in units or batches, which leads to a variation in flexibility and customization. This generally caters to small-scale production or a special price on products, where variety and exactness are required.

Depending on which method suits well, continuous production takes more speed and cost efficiency, and then batch production gives more freedom and control. It depends upon production needs and what the concern wants.

Maintaining Your Biscuit Machine

Daily and Monthly Maintenance Practices

📅 Daily Maintenance

- Look for and identify any visible wear or damage and make sure all parts are functioning well.

- After every operation, clean the machine to avoid build-ups and general residue from interfering with machine working.

- Check all lubrication points, if any, and apply lubrication as per instructions.

- Check all safety devices to see if they’re working.

📆 Monthly Maintenance

- Check belts, gears, and rollers for wear and adjust tension as necessary.

- Make sure all bolts and fasteners are tightened.

- Test sensors, controls, and electrical parts for their proper functioning.

- Make replacements of parts upon manufacturer recommendations when they are severely worn or nearing the end of their service time.

Note: Following these practices on a frequent basis will ensure that the machine is in good working order and has a long working life. For any peculiar recommendations, the manufacturer’s instructions should be followed.

Common Issues and Troubleshooting Tips

❌ Issue 1: The machine does not start

Cause: The Power supply is not connected or faulty.

Solution: Check the power cord from end to end, and also the outlet and circuit breaker. All connections should be secured; the outlet must provide power.

🔊 Issue 2: Unusual noises made during operation

Cause: There are loose components or a lack of lubrication.

Solution: Check to make sure no bolts or fasteners are loose. Ensure that all moving parts are lubricated as directed in the manual.

⚠️ Issue 3: Errors shown on the control panel

Cause: Sensor misalignment or failure.

Solution: Check the alignment of the sensor and clean if dirt or debris is found. Replacement of the sensor should be considered if faults persist.

📉 Issue 4: Depreciation of performances or output

Cause: Worn parts or clogging with debris.

Solution: Check all worn parts and replace them if necessary. Give a thorough cleaning to the cookie machine so as to remove any blockages or residue.

⚠️ Important: Adhere to all the safety recommendations and instructions provided by the manufacturer when doing any troubleshooting or maintenance work.

Working with Professionals for Maintenance

Those who operate a biscuit production machine understand that it has to be serviced on a regular basis. This should be done properly by professionals to achieve the best results. One of the best technicians is someone who is certified and has a lot of knowledge, who is able to understand the problem well, has the use of professional tools and equipment, and knows how to deal with situations that call for these specific methods. They can engage routine examinations that aid in conserving the machines by minimizing frequent malfunctions. Before hiring any professional service provider, you need to be sure of what kind of experience and qualifications they have with the type of equipment you are dealing with. Moreover, some description of the problem and maintenance history, in particular, can be very useful, such as in improving one’s service.

Future of Biscuit Production Technology

Innovations in Automatic Biscuit Making Machines

The most recent breakthroughs in the biscuit production machine are about improving productivity, accuracy, and flexibility. Advanced technology offers new solutions, and such machines have sensors and automation tools that serve shaping, baking, and packaging processes with excellent quality. Energy efficiency has become popular since it cuts the power costs while maintaining the current level of operations. In that regard, there has been the inclusion of modular systems, which provide easy customization of different modules in terms of biscuit or capacity. The above-mentioned step allows simplifying processes, reducing the amount of raw materials, and keeping up with shifting tendencies of consumers, especially in terms of their desires. This is a good outlook for the industry of biscuit production.

Adapting to Consumer Trends with New Biscuit Types

Manufacturers innovate by studying the requirements of the market in order to introduce new varieties of biscuits as demanded by the consumers. There comes an analysis of healthy ingredients for preferences like the usage of whole grains or less added sugars and goes further with examining new flavors and textures. Hands-on changes in social trends that include gluten-free or vegan ingredients help fellow manufacturers strategize their new biscuit production machine and methods to fit in new, demanding models.

Eco-Friendly Practices in Biscuit Production

Ensure baking choices emphasize environmentally friendly measures in biscuit production. These include:

- Lessening energy consumption by optimizing baking processes and investing in renewable energy resources

- Use packaging materials that are biodegradable and recyclable to reduce landfill waste

- Obtain ingredients in a sustainable manner, e.g., oils produced sustainably and utilizing local suppliers.

All these attempts pertain in some way to the scrubbed-up efforts to diminish the carbon footprints of the industry and green methods of production.

Frequently Asked Questions (FAQs)

Q: What do we call a biscuit production line?

A: A biscuit production line is a series of interlinked machines and equipment functioning as a continuous line for making biscuits: hard biscuits or soft ones. It applies the topmost technologies for utmost efficiency.

Q: How does a biscuit-making machine work?

A: The biscuit-making machine automates mixing, depositing, baking, and cooling of biscuit dough. The type of equipment could prepare a wide range of biscuit forms and sizes with dough making and biscuit forming vocabulary in the process-intended for industrial scale production.

Q: What would be the advantages in biscuit making?

A: The advantages of biscuit manufacturing include rapid or fast production of large quantities of biscuits so as to save labor charges through automatic or semi-automatic machines; whereas, the quality of the biscuits and the control of ingredients offer yet another character to those industrially manufactured biscuits.

Q: What are some important things that are to be preferred in relation to the purchase of biscuit-making machines?

A: Some factors to consider in the purchase of a biscuit-making machine would comprise capacity and production; particular biscuit types to be produced such as hard or soft biscuits; whether it will be manual or automatic; and the reputation of the suppliers. The purchaser must also look at maintenance and running costs as a continuation of their business in the long run.

Q: Can the same baking machines be used for cookie and biscuit production?

A: Yes, cookie-making machines can often be altered to produce several different types of biscuits that differ in color and shape, hence high flexibility for a bakery or food processing operation.

Q: What materials are required to produce biscuits?

A: Common materials in biscuit preparation remain wheat flours, sugar, fats, and emulsifiers. Additional regulators might be chocolate chips or nuts from the texture and taste point of view.

Q: What is factory acceptance testing in biscuit making?

A: The locution is a factory acceptance test that is run to verify that the biscuit machinery works according to specifications, before it is delivered to the client. The FAT will make sure that all functions, including the dough preparations and cooling systems, are up to the standards in terms of quality.

Q: What is a biscuit machinery manufacturer with a good reputation?

A: A reputable biscuit machinery manufacturer, apart from giving high-quality machines, will render comprehensive support, having stabilised repair records and always placing innovation and customer satisfaction in the biscuit production line first.

Q: What is the Difference between a manual biscuit-making machine and an automatic biscuit production line?

A: It is humanly involved in almost all processes in a manual biscuit-making machine, including shaping and baking, whereas fully automatic production is somehow an advanced technological extension, thereby speeding up biscuit production expeditiously with less output.

Q: Are used biscuit-making machines suitable for a lucrative investment?

A: Used biscuit-making machines might be cost-effective as good investments for small and medium bakeries if they are in good working condition and have repair records. They provide a little yet considerable entry cost into production with respect to operational advantages.

🎯 Key Takeaways

In many ways, learning about biscuit production machines helps in optimizing manufacturing processes, meeting the market demands, and ensuring that the quality of the products is retained. What equipment to buy in accordance with the specific production needs, or how to take care of the purchased equipment, all those aspects are very important when talking about biscuit production. The technologies that are in place now are such that any bakery business that embraces automation, sustainability, and change is bound to enjoy a longer success in this industry.

📚 Reference Sources

1. Fundamentals of In-Line Production by Peter R. Whiteley

- A book dealing with the latest automation, equipment, etc., in the biscuit industry.

- View Source

2. Biscuit

3. Machine

Related Posts

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.