You have found the correct recipe which produces fluffy biscuits...

Read MoreDiscover the Ultimate Biscuit Sandwich Machine: Revolutionizing Sandwich Biscuit Making

For many years, producing good-quality sandwich biscuits consistently, at an industrial level, has always been problematic for manufacturers. However, there have been technological changes in the processing capabilities of different foods, including the introduction of servo systems for improved performance within the confectionery sector. Introducing the Ultimate Biscuit Sandwich Machine, the latest equipment, which will revolutionize the way sandwich biscuits are made. This article will explain in detail the industrialization of sandwich biscuit manufacturing with this great machine, stressing how it will improve productivity, accuracy, and high quality in sandwich biscuit. Whether you are in the food processing industry or you just love understanding how things work, this comprehensive look at advanced biscuit-manufacturing technology will be very interesting and educational.

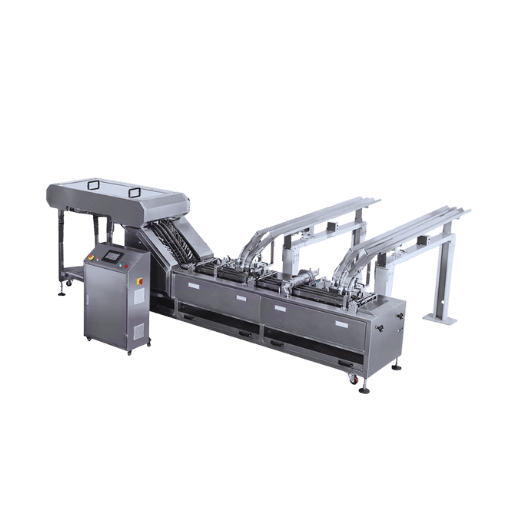

What is a Biscuit Sandwich Machine and How Does it Work?

A biscuit sandwich machine helps in the making of biscuit sandwiches, and it is a piece of equipment that is dedicated to that purpose. It achieves this by taking two biscuits and filling them with either a layer of cream, jam, or chocolate. Biscuits are then fed into the machine in a specific order, which has specialized tray loaders for maximal efficiency. The filling is applied evenly on one biscuit, and then another biscuit is put on top of it to create a sandwich. Such machines are urbanely designed to provide a uniform quality production, a rapid rate of production, and a reduced level of wastage as well; thus, they are vital equipment in the mass production of biscuits.

Understanding the Basics of a Biscuit Sandwich Machine

A biscuit sandwich machine is intended to facilitate the sandwich preparation process with precision and ease. The working principle of the sandwich machine is: it stacks biscuits correctly before smearing filling on one of them with the exact thickness, and adds another biscuit on top. Such machines can manage high-speed production and maintain product quality within the acceptable limits. The main part of such machines’ design involves the presence of a feeding device, filling device, arranging device, and controlling sensors. Hence, the machines are indispensable in large-scale biscuit manufacture owing to increased production and unemployment, as well as saving on waste material.

Key Features of Sandwiching Machines

- Fast-speed Operation:

Sandwiching machines have the ability to make thousands of sandwich biscuits per minute, thus providing efficiency to any large-volume production environment.

- Precision Alignment Mechanism:

Utilizing very special alignment mechanisms, these machines position biscuits and fillings with precision so that a uniform product quality is secured at the output.

- Various Filling Options:

Filling types can include creams, jams, or any type of spread, with filling quantities adjustable to baffle product requirements.

- Quality Control System Incorporated:

These machines, through the use of sensors and monitors, find out who is odd in the population of products and allow only the finer products to go forward.

- Easy Maintenance and Cleaning:

With user-friendly modular parts, these machines are justly designed to allow rapid maintenance and cleaning to stricter food safety measures.

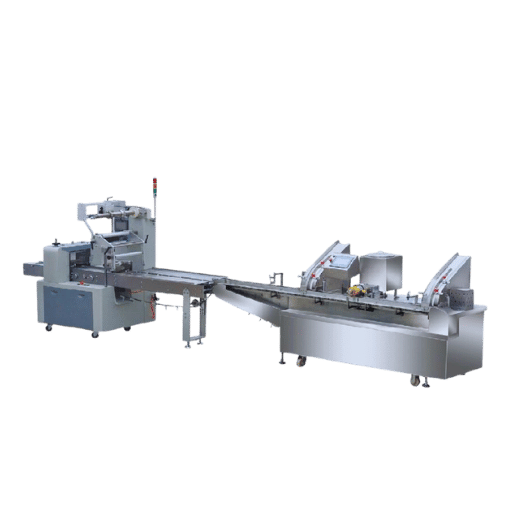

How Biscuit Sandwich Machines Integrate into Production Lines

Implementation of biscuit sandwich machines is smooth in production, and it increases the speed of assembling and packaging processes, especially in the case of hot sales. They follow after baking and subsequent cooling, where biscuits receive intricate feeding into the note machine. The filling is done thoroughly, every biscuit is positioned accurately, and the two are slid together quickly. Besides these, sandwich-making devices may be used with packing devices, whereby the amount of packing work utilizing hands is decreased and production increases in the number of units produced. The ability to address other users’ equipment uses also ensures that there shall be few interferences, if any, when they are put into use, and service for such users can grow as necessary.

Why Invest in a Biscuit Sandwich Machine?

Efficiency and Automation in Biscuit Sandwich Production

With a biscuit sandwich machine, production efficiency drastically increases, and production management becomes easier with the increase in demand. In other words, instead of the tedious process of filling, aligning, and sandwiching, these machines perform these processes, which saves time and contributes to lower labor costs and reduces mistakes. Furthermore, they are capable of producing high-quality products at faster speeds to meet the demand without necessarily lowering the already high standards. This is because they integrate with the existing production facilities, ensuring that they can curtail any operations or include extra capacity without any issues, hence making them very effective and cost-friendly for the current generation biscuit producers.

The Role of a Biscuit Sandwich Machine in Scaling Production

✓ Workers’ Exhaustion Reduced

A biscuit sandwich machine can offset the repetitive and mundane activities from the assembly line, and one can expect a better efficiency with the level and amount of production far surpassing those of manual methods.

✓ Standardization of the Product Quality

Equal application of the fillings, correct orientation, and proper sandwiching also help preserve the standard of the product even at the highest production levels with the help of equipment.

✓ Cost-Efficient Reduction of Labor

Moreover, appreciating the use of biscuit sandwich machines shifts energy from increasingly engaging workers to extensive improvement of technology and offers production rates suitable for vast expansion.

Cost-Benefit Analysis of Automatic Biscuit Making Machinery

Biscuit sandwich machine manufacturing can benefit in various ways by maximizing productivity and profitability through the installation of automatic machines. Major advantages of these machines enable higher output, lower cost, and better quality in products. These help in cutting down the cost as they help in reducing the wastage of ingredients, as well as labor, which contributes to the making of biscuits. Moreover, whether it’s flawlessness in products or consumers, every aspect shall be taken care of through the minimization of human intervention that augments uniformity, as well as other measures, such as in terms of the quality of the products. Even if it is considered a major initial expense, the monetary and additional operational benefits created in the long run will be much more than the cost factor, which is why the biscuit industry has also considered getting automated biscuit manufacturing machines.

How to Choose the Best Biscuit Sandwich Machine for Your Business?

Key Factors to Consider in Sandwich Biscuit Making Equipment

- 1

Production Capacity

Determine the capacity of the machinery so that it fits your requirements. Check for the number of biscuits made for one minute and how valid scaling is for your operations in the near future.

- 2

Automation Level

Establish an automation level best suited for your needs. Fully-automated machines require a lesser amount of intervention from operators; thereby providing a greater degree of efficiency and consistency, while semi-automated machines give you greater control over further small-scale production.

- 3

Versatility

It should withstand several biscuit types and shapes as well as fillings. It comes in handy if the business wants to diversify into product offerings to meet customer demand.

- 4

Quality and Durability

Analyze the quality of the machinery and how it has been put together. Machines built with good-grade stainless steel or other equally resilient materials promise durability, lower maintenance, and compliance with food safety laws.

- 5

Ease of Maintenance and Cleaning

Go for those machines that expose the least potential for disassembly and cleaning in terms of hygienic maintenance and downtime reduction. A self-cleaning system could certainly come in handy for reducing maintenance effort.

- 6

Cost and Return on Investment (ROI)

Evaluation of the value paid out upfront for the equipment against the benefits that it is able to provide in the long term. Evaluate operational efficiency, energy consumption, warranty, and so forth, so that a positive ROI can be justified for your business.

Comparing Top Biscuit Machine Suppliers

If you are going to evaluate and choose which supplier is the best for the production of a biscuit sandwich machine or the likes, I believe it will be prudent to evaluate the sample provision stated below: innovation, quality, and after-sales services. For example, it can be Sinofude, which has high-quality engineering, solutions to suit particular needs, and they are good at making customers come back. The machines are efficient as well as precise without compromising the quality, as they are made up to the standard required for production.

Evaluating Features: From Filling to Packaging

- Filling Accuracy

Machine producers consider the products being filled are fully quantified to prevent waste and ensure product consistency within a filling system.

- Speed and Efficiency

Assessing the machine operation speed necessary to meet production demands while maintaining quality.

- Material Compatibility

Testing the capability of the machines to work with various product types, viscosities, and container materials.

- Hygienic Design

Ensuring the hygienic and sanitation standards for food safety, including easy cleaning of the machines.

- Integration Capability

Considering the extent to which machinery integrates with the existing production floor and with automation systems.

Exploring the Types of Biscuit Sandwich Machines Available

Full Automatic vs. Semi-Automatic Machines

Fully automatic machines provide the best efficiency, consistency, and scalability for large-scale production. A semi-automatic kind of machine offers a little more flexibility and is cheaper and easier to use for smaller operations.

| Parameter | Full Automatic | Semi-Automatic |

|---|---|---|

| Efficiency | High | Moderate |

| Consistency | Precise | Variable |

| Scalability | Excellent | Limited |

| Labor Need | Minimal | Moderate |

| Cost | High | Low |

| Flexibility | Low | High |

| Ease of Use | Complex | Simple |

| Maintenance | Advanced | Basic |

| Production | Large-scale | Small to Medium |

| Automation | Full | Partial |

The Variety of Sandwich Biscuits You Can Produce

🍪 Cream-Filled Biscuits

Two layers of biscuit with a smooth cream filling sandwiched in between. Flavors include vanilla, chocolate, and strawberry.

🍓 Jam-Filled Biscuits

These include a layer of sweet and fruity jam, which imparts a different consistency and flavor.

🍫 Choco-Dipped Sandwich Biscuits

Biscuits sandwiched with creamy filling and chocolate-coated, either partially or fully, to enrich goodness.

🧀 Savory Sandwich Biscuits

This includes interesting combinations such as cheese or herb-flavored filling for those who like their biscuits without the sugar kick.

🎂 Multilayered Biscuits

Made up of biscuits separated with multiple layers of filling, it presents a more sophisticated and sumptuous treat.

Customization Options and Additional Features

- Flavor Variations

Fillings can be picked out from an immense collection of chocolate, vanilla, and strawberry flavors to savory ones, lots of cheese or herbs.

- Coating Choices

Chocolate and other sweet and savory layers can serve for partial coating or even full coating.

- Shape and Size

The proprietary biscuit could be designed in a shape and size peculiar to a given brand or consumer preference.

- Packaging Design

Custom packaging of one type or multipacks designed for retail, gifting, or bulk purchase needs.

- Dietary Preferences

Biscuit versions that cater to various dietary requirements–gluten-free, low-sugar, and vegan-to mention a few.

This way, customers ensure their choice is appealing, and the product is what the target market demands.

The Future of Biscuit Sandwiching and Packaging Technology

Innovations in Biscuit Sandwiching Equipment

Recent developments in biscuit sandwiching are all about augmenting operational efficiency, ensuring consistency, and improving the capabilities of customization. These improvements include automation systems that assist production by placing biscuits with precision and applying fillings with nearly no wastage. High-speed systems now include quality control, with optical sensors for very precise detection of any irregular sizing or filling distribution. Modular machinery allows manufacturers to move quickly between product configurations, capable of handling a greater variety of biscuit types and filling options. Hence, all developments went through intensive consideration of precision, scalability, and maintaining product consistency across the line, something important concerning biscuit packing operations.

Trends in Automatic Soft Biscuit Production

Automation and Efficiency

Owing to advances in automation, efficiency has greatly increased, as this, in fact, limits manual intervention. Automated processes can guarantee consistent quality and also maximize production speed.

Customization and Flexibility

With new equipment, bigger customization is now possible to allow the manufacturers to make a bigger or smaller range of biscuit shapes, sizes, and fillings depending upon consumer demands.

Sustainability

Sustainability is a very important consideration, where most of the systems are designed to save energy and reduce waste during production.

Data-Driven Processes

The implementation of data analytics and machine learning allows for real-time exacting monitoring and adjusting of production parameters, thereby improving quality control and lowering operational costs in cream biscuit manufacture.

Hygienic Design

Industrial designers prefer hygiene and may opt for designs that allow thorough cleaning under very strict food standards.

Sustainability and Efficiency in Biscuit Manufacturing

The following key considerations are generally regarded as essential to sustain and increase the efficiency of biscuit manufacture:

- Ensuring the utilization of ovens and machinery with energy efficiency to minimize overall energy consumption

- Ingredient waste minimization by way of recipe optimization leads to the most economically efficient production

- Water recycling systems plus better wastewater management bear the least environmental impact

- Raw materials are procured from sources that embrace sustainability as part of their work culture.

When used in tandem, these strategies serve to increase efficiency from the point of operation when complying with set environmental standards.

Frequently Asked Questions (FAQs)

Q: What is a biscuit sandwich machine?

A: This machinery belongs to a very special category of food machinery used for making biscuit sandwiches filled with any sort of cream or jam. It acts as the automizer in the sandwiching process and thus helps in efficient functioning of the production lines.

Q: How does one end up with biscuit production?

A: One-hour biscuit production line, meaning a series of related machines working jointly: biscuit-making machines, biscuit-cream-sanding machines, and packing machines. Every work: one has maybe to mix dough or ingredients; the other one to wrap or pack the finished biscuit for very high output with great consistency.

Q: What are major features of a biscuit cream sandwiching machine?

A: The biscuit cream sandwiching machine feels alone in common features such as the use of an easy PLC control panel for operation, a touch screen, and compatibility with a variety of cream fillings. They are usually polished in stainless steel and aluminum so as to maintain hygiene and ease surface cleaning.

Q: Can biscuit sandwich machine operations be carried out with different kinds of cream flavors?

A: Yes, numerous biscuit sandwich machines are designed to handle different types of cream flavors. If acquired, this sort of versatility enables the manufacturers to put out different types of biscuit sandwiches that consumers in various preference markets might go for.

Q: What is some preventive maintenance for biscuit packaging machines?

A: Maintenance activities keep biscuit packaging machines working smoothly. In maintenance, the machine is cleaned, moving parts lubricated, and these parts checked for wear and tear. In following the instructions specified by the manufacturer, life can be extended for a machine.

Q: Why would one invest in the fully automatic biscuit-making machine?

A: In a large factory, the biscuit-making machine works fully automatically; hence, it improves productivity as it automatizes the whole procedure from dough preparation to packaging of biscuits. There is no labor cost involved and some consistency in quality is maintained when producing huge quantities of biscuits.

Q: How can one obtain and maintain high standards of hygiene in biscuit processing?

A: High standards of hygiene should be maintained in biscuit making, that is, materials useful for machines should be food grade, all equipment should be cleaned and sanitized regularly, and operating staff should follow hygienic procedures while producing.

Q: What are the advantages of buying a biscuit sandwich machine direct from the factory?

A: Buying a direct-from-factory biscuit sandwich machine could reduce the initial investment costs of the manufacturer. Such a deal would be suited for new setups or companies trying to expand production levels in the near future but running low on funds.

Q: What functions does a conveying system serve in biscuit production lines?

A: Conveyor systems hold a key position in the production lines of biscuits as they are required for smooth passage of the products through varied stages of processing. They provide a continuous flow of operations so that handling times are kept short, thereby imparting efficiencies to the biscuit processes.

Q: What kinds of biscuit sandwiches can be made with this machine?

A: Biscuit sandwich machines may be employed for the manufacture of all kinds of biscuit sandwiches, including soft biscuit sandwiches filled with cream and jam; double biscuit sandwiches consisting of two fillings; and special shapes that come up as a demand of the consumers.

Related Posts

- Biscuit Press Machines A Game-Changer for High-Quality and Time-Saving Baking

- Biscuit Packing Machine: Understanding Efficient Packaging Solutions

- How to Bake the Perfect Fluffy American Biscuit at Home

- What is Popping Boba Made Of? Discover the Secrets to Perfect Popping Boba!

- Sweet and Gummy Pink Pig Candy: Delicious Pig Gummies for a Sweet Treat

- QQ Candy: Everything You Need to Know About These Delicious Gummy Treats

- Discover What Gummy Bears Are Made Of, Unveiling the Secrets Behind Your Favorite Gummy Candies

- Premium Japanese Ramune Candy Collection from Morinaga | Shop Now for Authentic Soda Treats on Japan Candy Store

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.