You have found the correct recipe which produces fluffy biscuits...

Read MoreExploring the Advanced Features of Modern Biscuit Wrapping Machines for Efficiency

Biscuits are consumed all over the world, with the morning’s first one being a simple pleasure and the chocolate chip one being a comfort delight. As basic as their production is, fewer people realize the very complicated journey of a biscuit from the factory to their home. One important part of this journey is the packaging. Right packaging means freshness is kept, the product is shielded from breakage, and the product is presented appealingly to the consumers. The biscuit wrapper is the very machine that makes your biscuit-wrapping flourish, as it is highly sophisticated and a very necessary tool in every bakery or food production plant of huge scale.

This guide will dive deeply into the topic of biscuit packaging starting from the production process and then to the high-tech features of present-day wrapping machines. We will see what types of machines have been made available, deliberate the significance of the duo – efficiency and sustainability, and offer suggestions that could facilitate your decision in getting the packaging system that best suits your company. If you get to know the tech and its uses, you will be able to effectively maneuver at the production line, at the same time cutting costs and giving the best product possible to your customers.

Understanding the Biscuit Production and Packaging Process

Overview of Biscuit Production Processes

Have you ever wondered how a biscuit begins its travel? It all comes down to the mixing of raw ingredients such as flour, sugar, fat, and water to do a dough. The dough is then shaped whereby it is commonly done by passing through rollers and cutters thereby creating the individual biscuits. The next step is to send them to long, industrial ovens for baking until they get the right color and texture. Additionally, those who have gone through baking must undergo a cooling process on long conveyors so that the biscuits do not get soft and are also prepared for packaging.

It is at this post-cooling stage that the packaging process begins. Efficient packaging is critical to maintaining the quality established during production. It needs to happen quickly to preserve freshness and gently to avoid breaking the delicate, freshly baked products.

The Importance of Efficient Biscuit Packaging

Why is efficient packaging so important? There are several key reasons:

Product Protection: Biscuits are fragile. Proper packaging shields them from moisture, which can make them soft, and from physical impacts that cause breakage. This ensures the product reaches the consumer in the condition it left the factory.

Shelf Life Extension: An airtight seal is essential for keeping biscuits fresh. Effective packaging prevents oxidation and contamination, significantly extending the product’s shelf life.

Brand Presentation: The package is the first thing a customer sees. High-quality, attractive packaging can influence purchasing decisions and reinforce brand identity. Consistency in packaging reflects a professional and reliable operation.

Operational Efficiency: In a high-volume production environment, the speed of the packaging line directly impacts overall output. A slow or unreliable wrapping machine can create bottlenecks, reducing productivity and increasing per-unit costs.

Types of Biscuit Wrapping Machines

Automatic Biscuit Wrapping Machines

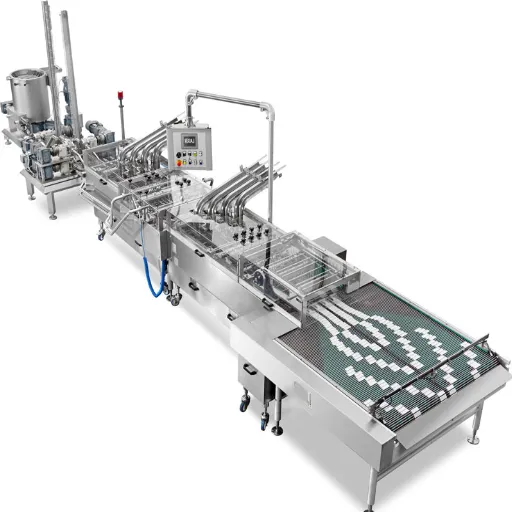

biscuit packing system and put it next to cooling conveyor this biscuit packaging line this whole set-up connects cooling conveyor and biscuit wrapping machine biscuit wrapping machine which is one of them knocking off ready-packed biscuit boxes consectetur adipisicing elit. the machines are so that they can count, stack and wrap the biscuits before the packages are sealed. you can clearly see how automation in the system until its still the best in large scale, due to speed and consistency being the main factors. the machines also cut down on labor costs as well as human error, more so they are capable of operating non-stop at very high speeds, often more than a hundred wraps in one minute.

Flow Wrap Machines for Biscuit Packaging

One of the typical machinery types used for biscuit packaging is the flow wrap machine, also referred to as the horizontal form-fill-seal (HFFS) machine. The operation of these machines is quite simple: a flat film roll is changed into a tube continuously enclosing the biscuits, which are let in the tube. The longitudinal seal is produced by the machine either on the lower or upper side of the tube, followed by the transverse seals on both the front and back parts of the biscuit aggregates, which separates them into packs.

Flow wrappers are immensely versatile and can cover a broad spectrum of product sizes and shapes. They are effective, produce a seal that is both tight and secure, and can be used for both wrapping single biscuits, or a stack, or a pile. This adaptability has turned them into a top option for the broad range of products from tiny snack sacks for one serving to the big family-size packages.

On-Edge Biscuit Packing Solutions

It is a well-known fact that the third dimension orientation of the various biscuit products plays a major role in providing the customer with the benefits in packaging. Biscuits are one of the most consumed snacks worldwide, and for that reason, biscuit packaging has been a great area of development and innovation to make the process of consumer access to the product easier, more convenient, and less wasteful. A specific example is the on-edge biscuit packing technology which is quite widely used in the biscuit industry.

Advanced Features of Modern Biscuit Packing Machines

Cutting-Edge Technology in Biscuit Wrapping

Today’s leading biscuit packing machines incorporate several advanced technologies:

Servo Motor Control: Modern machinery has shifted from the old method of employing a mechanical drive to using multiple servo motors to maneuver the various sections of the process like the film feed, product infeed, and sealing jaws. This technology enables the making of very fine, separately controlled changes in operation, which, in turn, results in less wasted time due to other operations, quicker changeovers between the product sizes and the higher precision of the wrapping process.

Smart Sensors and Vision Systems: High-resolution cameras and advanced sensors can detect product misplacements, double-feeds, or imperfections. If an issue is detected, the machine can automatically reject the faulty pack without stopping the entire line, minimizing waste and downtime.

HMI Touchscreens: User-friendly Human-Machine Interface (HMI) touchscreens provide intuitive control over the machine. Operators can easily set parameters, store recipes for different products, monitor performance in real-time, and troubleshoot issues with on-screen diagnostics.

Automation and Efficiency in Packaging Lines

According to their capacity to use all available resources, automating is the foremost factor. A packaging line that is run on full automation can accommodate various machines such as the one for stacking biscuits and the other for packaging the final cases. Robots can be employed to take the packs of biscuits wrapped into the secondary packaging like the cartons or the boxes. This fully automated production line not only eliminates the human workforce but also speeds up the process and guarantees the smooth movement of goods from the production site to the palletizing section.

Customizability of Biscuit Packaging Equipment

All biscuit manufacturing lines have their unique characteristics. However, the suppliers of packaging machinery acknowledge this fact and they provide a high level of custom-made products. The machines can be made to accept particular biscuit shapes, dimensions, and textures. The infeed systems, being the most critical part of the whole line, can be configured to match an oven’s output and the wrapping materials can be environmentally sustainable as well as branded. Therefore, the customization aspect makes the packaging equipment a perfect choice for your specific operational needs.

Choosing the Right Packaging System for Your Business

Meeting Packaging Requirements for Different Products

Consider the variety of products you produce. Do you primarily make one type of biscuit, or do you have a diverse portfolio including crackers, sandwich cookies, and other baked goods?

Crackers and Hard Biscuits: These are often packaged on-edge. A system with a reliable on-edge feeder and a flow wrapper is typically the best solution.

Soft or Cream-Filled Biscuits: These delicate products may require gentle handling to avoid damage or cream smearing. Machines with specialized “no-crush” infeed systems are essential.

Pile or “Slug” Packs: For packaging a stack of biscuits lying flat, a standard flow wrapper with an appropriate feeding system is sufficient.

Your machine should be flexible enough to handle your current product range and potentially new products you plan to launch in the future.

Sustainable Packaging Options

Sustainability has become an area of concern that is no longer on the fringe but at the very center of business. Both consumers and regulators are now calling for a higher level of packaging that is environmentally friendly. The manufactory of biscuit wrapping machines is now involving technology that can manage a wide range of sustainable materials notably:

Recyclable Mono-Material Films: These films are made from a single type of plastic, making them easier to recycle than traditional multi-layer films.

Compostable or Biodegradable Films: Made from plant-based materials, these films can break down under specific conditions, reducing landfill waste.

Paper-Based Wrappers: Paper is a renewable resource and is widely recyclable. New paper-based films with barrier properties are becoming a viable alternative to plastic.

When choosing a machine, ensure it can effectively seal and cut these newer, sometimes more challenging, materials.

Comparing Biscuit Wrapping Machines

Cost Efficiency of Different Packaging Machines

The initial purchase price is only one part of the total cost of ownership. To evaluate cost efficiency, consider:

Operating Costs: How much energy does the machine consume? What are the labor requirements?

Maintenance Costs: Are spare parts readily available and affordable? How much downtime can be expected for routine maintenance?

Material Waste: How much film is wasted during startup, changeovers, or due to rejected packs? An efficient machine minimizes waste, saving money over time.

A cheaper machine might have higher operating costs or lower reliability, making it more expensive in the long run.

Performance Metrics in Biscuit Packing Machines

When comparing machines, look at key performance indicators (KPIs):

| Performance Metric | Description |

|---|---|

| Packs Per Minute (PPM) | This is the machine’s maximum speed. Ensure it can keep up with your production output. |

| Overall Equipment Effectiveness (OEE) | OEE is a measure of how well a machine performs relative to its full potential. It considers availability (downtime), performance (speed), and quality (rejected packs). A high OEE score indicates a reliable and efficient machine. |

| Changeover Time | How long does it take to switch from one product or package size to another? Fast and simple changeovers are crucial for businesses with diverse product lines. |

User Reviews and Industry Insights

Finally, never belittle the significance of the feedback provided by other users. You might want to find case studies, testimonials, and user reviews. It is always a good idea to go to trade shows, where you can see the machines in action, and talk with the manufacturers and their customers. Industry forums and professional networks are excellent sources as well, to get unbiased insights on the rather practical sides of the different brands’ performance and reliability.

Reference Sources

- Biscuit Packing Machines: Types, Benefits & How They Work – Lintyco

Biscuit Packing Machines: Essential Equipment for Modern Food Industry – Soontrue

How Biscuit Packaging Machines Improve Efficiency and Product Quality – Suntech

Efficient Biscuits, Lollipop, and Ketchup Packing Machines for Modern Food Production – Baopack

Frequently Asked Questions (FAQs)

What is a biscuit wrapping machine and how does it operate?

A biscuit wrapping machine is a kind of packaging equipment that is specifically designed for the efficient wrapping of biscuits and crackers. A typically used feature in most of the machines is a feeding system that feeder biscuits into the packaging line, as a result, providing a constant flow. Higher technological sophisticated models, like the ones having a horizontal flow wrap design, take advantage of high speed packaging technology for the continuous production. In this way, the wrapping process may benefit from the use of a superior quality packaging film which also ensures the product’s freshness. Quite a few of the biscuit wrapping machines have a simple operating procedure and need very little manual intervention.

What are the benefits of using an automatic biscuit packing machine?

An automatic cookie package system is undoubtedly more beneficial when compared to manual packaging activities. On one hand, it greatly hastens the packing processes, making the plant’s total output possibly higher. By efficient marketing provision, these machines take care of the needs of different customers, such as the regulatory requirements for cleanliness. Moreover, the machines are built with good and strong materials, mainly stainless steel, thus making them sturdy. They are also, due to their flexibility in having the packing position and method changed, able to satisfy different product packaging needs in the bakery market and even beyond.

How does a biscuit packaging machine ensure packaging quality?

A biscuit packaging system employs advanced technology and exact manufacturing techniques to provide packaging quality assurance. Good quality packaging materials have been selected to ensure freshness and prevent product damage especially during transportation. A lot of machines are supplied with fault self-diagnosis, which is a very useful feature, considering it assists in the proactive identification and correction of problems. The design of the machine also targets to minimize handling at the same time without any breakage, thus preserving the biscuits’ aesthetic appeal. To mention a few examples, by conforming to GMP (Good Manufacturing Practices) these machines are able to meet the criteria required for food packaging that are quite tough in terms of quality.

What types of biscuits can be packaged with a biscuit packing machine?

The biscuit-wrapping machine is the one and is good to go with various things being filled out. Also, some of the biscuits are such that filled biscuits, and otherwise, crispy crackers as well as the delicate cookies, the machine can handle them all. This mixing of sizes and shapes within a single type of product is the machine’s job best until it again starts showing the products the way they were before. Different from he most automated processes, the smaller batches get produced by the artisanal players. For the ones that are into high-tech and fast applications, processing is their man. The universal characteristic is that they can embrace the bakery industry without limitation, and thus the market shares and the operations are shifted as and when.

What packaging solutions are available for biscuit wrapping machines?

Biscuit wrapping machines are available in a variety of capacities and can be chosen for several different kinds of needs. They can produce pillow packs, multi-packs, and granule packing for different product segments. Packaging operations are automated on these machines thus the packaging procedure is made fast and less manpower is needed. On top of that, the more advanced versions also have things like cartoning and case packing as part of the equipment, making it a more comprehensive packaging system. The products are not only in beautiful and eye-catching packages but are also safe when they are stored and moved due to these packaging solutions.

How do I choose the right biscuit wrapping machine for my production line?

Selecting the proper biscuit wrapping machine is a procedure which has to be carefully thought about, with a few particular aspects to be looked at such as production capacity as well as packaging speed. The biscuits to be packaged, including their packaging requirements, are to be assessed and this will lead to the determination of the machine’s favorable qualities. The machines, which are trouble-free in operation and have simple maintenance, are to be sought after, as they will be time and cost-saving equipment. Also, take into account the machine to be efficient in the product changeover that is a must for satisfying the market’s demands. Moreover, thermoforming packaging machines and vacuum packaging machines are different in terms of primary food processing. The last consideration is for the packaging machine to be following the sanitation rules and to be of a long-lasting stainless steel structure.

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.