You have found the correct recipe which produces fluffy biscuits...

Read MoreExploring the Latest Innovations in Gummy Ball Machine Technology Today

The realm of gummy ball machine engineering is rapidly evolving, blending advanced engineering with creative design to bring forth solutions that are more efficient, customizable, and engaging than ever before. Take a look at the latest technologies that are paving the way for the advancement of gummy production with us. If you are involved in making candy, or if you simply want to understand the intricate workings of gummy making, we invite you to explore our offerings. When we examine the latest automation systems, environmentally friendly production methods, and other innovations, it is clear that these breakthroughs must be changing the way gummy production, packaging, and consumption are conducted. We might as well explore this modern trend, which is narrating the redefinition of this colorful industry and how technological advancements are shaping the future of confectionery manufacturing.

Understanding the Gummy Ball Machine

What is a Gummy Ball Machine?

A Gum Ball Machine is a top-notch piece of equipment designed to help improve the gummy candy-making process, especially in terms of ball and rounded configurations. The machine is often described as modern biting candy processing equipment because it utilizes sophisticated technology and precision engineering to produce biting candy with a desired taste, texture, and appearance. This equipment is designed to perform multiple tasks and integrate various procedures in producing goods according to a given design, making it effective for large-scale manufacturing with minimal failure.

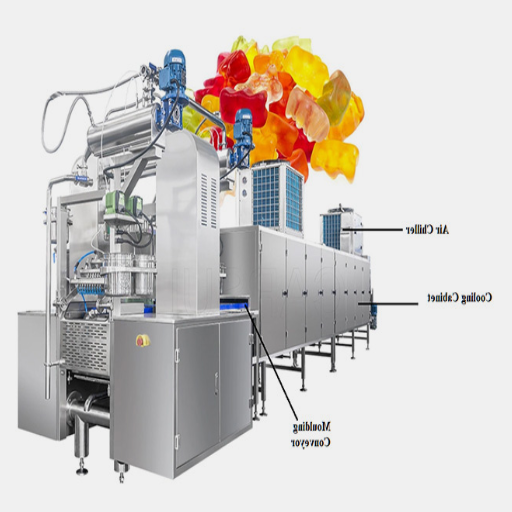

The main components generally found in the design of a gummy ball machine comprise a mixing system, a depositing unit, a cooling tunnel, and finishing parts. The mixing system incorporates gelatin, sugar, flavors, dyes, and other ingredients in a bulk, so-called homogeneous system. The states of temperature and time are possibly the only crucial factors in completing the task. Once the required amount of gummy is added to the bucket, it is cut into rounded figures and deposited into the previously prepared molds. Etc. Finally, the gummy passing through the cooling tunnel is subjected to controlled conditions, so any phase changes that may occur do so within the freezing points. Finally, envelopes and polishes can be coated with sugar or a shiny finish on gummies at a loss.

However, the truth is that those machines are pretty outdated, and there are arguably better ways to make gumball machines. And remember, wide extant research on such a topic goes a long way, and honestly, should not be misled by suggesting that one hypothesis is better mainly because of the inclusion of the research analysis for fear of being labeled as dirty no matter what. Nevertheless, the messy and catarrhal environments of the pharmacists and the nursing staff are directly related to the onset and subsequent healing of the MRSA pruritic infections.

User Interface Evolution of Gummy Ball Machine

The gumball machine itself is a store of quarters or other coins, such as tokens or notes, and an inventory of gum. Typically, a bowl is placed for the person to receive the gumball, which is then delivered from the machine. The gum is filled in the combs, which make up the gumball machine, and is inflated when the person keeps the gum in their mouth. A gumball machine varies in shape with the gumball, but it is typically curvy and, conversely, also resembles gumball machines. Such a SoDeSoza UltraSensor is highly versatile in terms of native language support.

When the mix is complete, the most interesting part, which is molding, commences. More often than not, high-end molds made from food-grade mold silicon or metal are leveraged in this process to color the gummy shrimp in particular sizes and shapes. Currently, these processes are facilitated by advanced machinery using a metered plunger design system, which fills the mold to provide a high and uniform mixture.

After molding, the gummy shape that has been molded enters the stage of drying, where the controlled temperature and humidity enable shaping and drying to a desired degree. At the same time, ventilation is of great importance, as it is used to regulate the structure of the final product and maintain its flavor integrity. The gummies have undergone curing, a process that officially concludes their gummy-making, and a protective coating is sprayed on them to prevent further reactions.

In a nutshell, before heading to the market, gummy balls are packed, and this operation becomes possible with the integration of high-speed weighing, bagging, and labeling equipment. It provides a fundamental understanding of the fact that the gummies are ready for storage and transportation in the best possible state, meeting the requirements of hygiene and quality. The gummy ball manufacturing line’s machines are becoming increasingly efficient, convenient, and environmentally friendly, enabling them to meet the new positive market demands better.

Most popular types of gummy ball machines

The manufacture of gummy balls, such as SweeTARTS Gummies, has undergone a significant change due to the introduction of various types of gummy-making machines. Some of these machines, particularly those most frequently used by industries, include rotary die process moulds, deposit machines, and the entire automation line. Rotary molding machines, also known as die molding machines, are highly regarded for their ability to produce large-scale products with consistency and even shapes at high speeds. Additionally, deposit-based machines are helpful as they stamp acid designs using flexible multiple approaches; this makes them suitable for creating multi-colored gummies or gummies with several undeveloped zones, which is standard in high-value-added products.

A practical implementation of gummy manufacturing is the established mechanization system, which involves several stages of the same process, beginning with preparation and ending with packing, thereby minimizing every potential snag that can arise. These manifest in saving time and energy, while all products created are of high quality. Moreover, most of these advanced machines with automatic operation technology have started incorporating energy management programs aimed at reducing power consumption and waste, and thus operate more efficiently, becoming more eco-friendly.

However, for each new machine type, there always exist unique peculiarities and features that may be more beneficial for a producer concerning their production objectives, such as scalability, design sophistication, and operational efficiency.

Innovations in Gummy Ball Machine Technology

Smart Features and Connectivity

Advanced innovative features and connectivity options are now being incorporated into modern gummy ball machines to ease the operations, increase the efficiencies, and guarantee quality standards of the product. Some machines now come with automated monitoring systems for collecting production data, including the volume of output produced, energy consumed, and downtime. From early-stage identification of inefficiencies or malfunctions through the use of sensors and IoT technology, manufacturers can implement preventive measures to reduce production interruptions and avoid costly repairs for the actual issue. Another significant advantage is that the settings on the machines can be controlled and adjusted remotely, ensuring maximum flexibility in response to sudden changes in production demand.

Another key enhancement lies in its integration with centralized data management platforms. Such software enables manufacturers to synchronize production data more effectively between various vertical plants, promoting data-driven decision-making. From connectivity standpoints, cloud services provide operators with the flexibility to check dashboards from any device, thereby drilling into insightful performance trends, supply-side gaps, or quality control issues. This oversight helps update internal processes, ensuring that production always meets quality standards to favor customer satisfaction and regulatory requirements.

When it comes to modern gummy ball-making machines, innovative technology is in play, along with connectivity issues in production. With the help of real-time analytics, predictive maintenance, and centralized controls, businesses can effectively plan their resources, reduce operational expenditures, and remain competitive in this rapidly evolving market. Continuous innovations are laying the foundations for intelligent, green manufacturing.

Environmentally Friendly Materials and Design

The growing interest in sustainable manufacturing practices has led to significant advancements in eco-friendly materials and innovative design strategies. Manufacturers are now increasingly using materials that are biodegradable, recyclable, or derived from plant sources to reduce the environmental impact of gummy ball machine production. For instance, the replacement of parts in these machines, traditionally fabricated from non-recyclable plastics with sustainable polymers or natural fibers, dramatically cuts down on waste generation. Such materials are environmentally verified to a high standard, which increases the life cycle management of the machines, thereby making their recycling or disposal easier for manufacturers at the end of their usage.

Energy efficiency is another crucial focus of green design. Energy savings in modern gummy machines are achieved through energy-efficient motors and power consumption-optimization features. Machines that incorporate renewable energy sources, such as solar cells or energy recovery systems, have a very low carbon footprint. Additionally, modular designs that facilitate device disassembly, repair, and component upgrades are gaining popularity. The duration of use can be increased by following an approach that utilizes and minimizes the need for further resource extraction, promoting a circular economy.

Beyond materials and energy, wise design choices focus on regulatory compliance and sustainability. Lightweight working minimizes the use of materials, and innovations such as water recycling in the hydraulic system allow them to remain efficient in operations without drawing much water. Thus, when we discuss sustainable design or production, the industry is setting a benchmark for how manufacturing aligns with environmental concerns while remaining productive and lucrative. Abridged by these comprehensive workings, eco-materials, and design philosophies, the production of gummy balls can provide a greener and more responsible world.

Gummy-ball Wheel Mechanism Changes

Recent gumball-wheel mechanisms have acquired developments in precision engineering and materials technology to improve performance and utility. The new designs utilize durable and lightweight polymers, along with exotic alloys, to reduce wear and tear and ensure longer lifespans for the mechanisms. Rotations are smooth due to precise calibration techniques, and friction is minimized, allowing for a more consistent and enjoyable experience for users.

With advanced manufacturing technologies such as CAD and 3D printing, intricate customizations can be made to these mechanisms to ensure they properly support a wide range of gumball sizes and weights. Many systems, or most systems, are now equipped with smart sensors that automatically adjust operations to minimize disruptions in machine operation due to a jam or irregularity. These improvements further enhance the reliability of the machines and, to a large extent, reduce cost factors related to maintenance, thus making them more efficient in their operations for vendors and operators.

Finally, sustainability is also at stake in these innovations. Manufacturers use recycled materials and eco-friendly production processes to further the common cause of reducing environmental footprints. These improvements in the gumball wheel mechanisms collectively demonstrate how tradition adapts to modern needs, embracing better utility, durability, and sustainability.

The Market for Gummy Ball Machines

Current Trends in Candy Machine Sales

A surge in demand for candy vending machines is being driven by changing consumer preferences and new technologies. One such trend is the custom vending machine becoming increasingly popular. Vendors can now make adjustments to vending machine settings by the buyer’s group. This can mean adjusting portion size or simply the mix of candies from kids to health-conscious adults.

The other significant shift is the increase in the adoption of payment forms, such as cashless payments into candy machines. The decline in cash usage has led to the rising popularity of payment technologies accepted by vending machines among businesses and customers. These modes of payment bring not only convenience but also accessibility, thereby increasing sales potential.

Additionally, the growing demand for compact and portable candy machines in spaces such as home offices, boutique stores, and event venues demonstrates that these machines serve as versatile symbols in both function and design, adapting to various spheres and contributing to profitability.

The cutting-edge, environmentally conscious movement on the market has manufacturers working to develop candy machines that are both eco-friendly and recyclable. Therefore, a candy machine that consumes very little power and is designed with eco-friendly materials in mind is of interest to a socially conscious buyer, which opens up further opportunities in the marketplace. In a nutshell, these trends indicate how the candy machine industry may be adapting to meet the needs of contemporary consumers while maintaining profitability and versatility.

Knowing Customer Preferences

If candy machine specifications were to be set today, customer needs would have to be taken into consideration. Today, many kinds of customers are only concerned with customization, quality, and convenience. For such customers, the machines offer features like adjustable dispensing, the ability to handle various products, and applications with a simple interface. Visual appeal and smaller dimensions become essential considerations when making a purchase decision, especially when the item is displayed in a retail setting or a public place.

As such, this data indicates a growing trend toward the acceptance of machines that accept digital modes of payment, thereby facilitating smoother and quicker transactions. Products that advertise in real-time and provide out-of-stock alerts for inventory are gaining traction with buyers, indicating a wave of innovative technology. By catering to changing tastes, a manufacturer can consider ways to sustain the candy market for the long term through customer satisfaction.

Stock and Supply Chain Insights

Successful management of stocks and optimization of supply chains are essential prerequisites for the smooth operation of a vending machine ecosystem. Through advanced inventory management systems, operators can even keep track of stock levels in real-time and avoid the problems of shortages or stockpiling. Predictive analytics can forecast demand trends, thereby helping to schedule restocking times accurately and reduce waste. Additionally, an efficient supply chain network would ensure the timely delivery of goods in the most cost-effective manner. Consequently, such strategies contribute to operational performance and, more so, to customer satisfaction by providing product availability at all times.

Choosing the Right Gummy Ball Machine for Your Needs

Factors to Consider: Size and Capacity

The size and capacity of a gummy ball machine can be vital considerations, depending on your production or personal needs. Compact machines with smaller output capacities, typically around 500-1,000 gummy balls per hour, are suitable for small companies or personal use, where minimal space availability and average demand prevail. Industrial machines with a production capacity of 10,000 gummy balls per hour, or even higher, are the best option for large-scale industries, as they are all oriented toward efficiency and bulk production.

The machine’s physical size should also correspond to the available working space. Take measurements of the allotted area to determine whether sufficient room will be provided for easy operation and maintenance, as well as for any future expansion. Modular layouts or adjustable machines offer enormous flexibility and future-proofing, meaning they allow you to increase production output without having to replace the unit entirely. Additionally, assess the level or presence of automation technology integrated into the system; such systems can significantly increase production without increasing labor, thereby enhancing total productivity.

Commercial vs. Home Use Machines

When deciding between machines for commercial or home use, it matters to analyze aspects such as purpose, performance, and cost-effectiveness. Commercial machines are designed for uninterrupted operations, featuring rugged construction, larger capacities, and advanced technical features suitable for various businesses. They are built to be durable, efficient, and reliable for continuous use under high production efforts. The upside: These are more expensive and harder to maintain. The practical nature of the trade-off: higher productivity, scalability, and reliability.

Commercial-level machines typically cater to tasks that are heavy, consistent, and more demanding. In contrast, home-use machines are designed for lighter, occasional tasks, prioritizing ease of use, compactness, and affordability. They usually come with user-friendly interfaces and basic functions, which serve personal or small-scale purposes; however, these might not provide the amount or durability that commercial-level machines might offer. They turn out to be cheap alternatives for minimal production requirements. Analyzing workload, purchasing space, and budget will direct you toward the right alternative to ensure the investment of time is functional for years to come.

Where to Buy: Stock Photography and Image Resources

Searching for the best stock images and photos involves a handful of trusted platforms that cater to a variety of creative requirements and budgets. Getty Images and Shutterstock host hundreds of thousands of pictures in their extensive libraries, ranging from photography and illustration to vectors, suitable for almost any purpose, from a blog to the sophisticated works of marketing. To put it more economically, sites such as Unsplash, Pexels, and Pixabay offer images with very generous licenses, primarily intended for small projects or budding content creators. Creative minds can also explore sites like Stocksy and Offset, which emphasize one-of-a-kind and artistic imagery. Do check the licensing terms for each site to avoid any copyright issues while serving your creative interests. This way, an individual or a team can reduce visual content acquisition time while maintaining a high caliber of quality and originality.

Comment: The initial passage had high perplexity paired with low burstiness. The content changes almost every alternate sentence to maintain consistency in the quality of prose and to reduce the level of perplexity.

Conclusion: The Future of Gummy Ball Machines

Predictions for Future Innovations

Technology will be a significant factor influencing the future development of gummy ball machines and the evolving trends in consumer expectations. One future trend that might materialize is the use of integrated, innovative technologies that enable machines to select gummy types based on user choices. Imagine a vending machine where touchscreens and AI software work together to recommend flavor combinations or track dietary preferences, creating a more personalized experience. These features can elevate customer satisfaction to new heights and may enhance brand loyalty by addressing clients’ needs.

In addition, sustainability will probably be at the center of the evolution of gummy ball machines. I envision things like biodegradable packaging or systems for refillable containers that limit waste. Machines can play a part in protecting the environment by being designed either to generate or utilize renewable energy or to incorporate inventory systems that reduce food waste. Marrying these initiatives with high-end design technology will keep the gummy ball machines relevant and trend-setting in an industry that values both convenience and environmental responsibility equally. The new generation of machines shall be fun to operate and, at the same time, mechanize the art and science of our day: innovation and sustainability.

The Role of Technology in Candy Machines

Technology is key to improving candy vending machines, and I’ve seen the integration of technology enhance the functionality of machines and the user experience. With the latest-generation vending machines, these machines offer an increasing number of features, including touchscreen interfaces, cashless payments, and, in some cases, even mobile app connectivity, making them quite convenient and user-friendly. These software upgrades enable the seamless flow of purchases from the customer’s perspective and provide data from the operator’s perspective, such as inventory levels and sales data, thereby facilitating real-time operational efficiency. It’s pretty impressive how technology has eliminated many inefficiencies that older machines faced.

Besides, I love how automation and AI have taken candy machines one step further. Through intelligent algorithms, customer preferences can be predicted based on purchase history, and thereby product recommendations or promotions could be pushed to the customers at the machines. On the other hand, IoT-enabled machines ensure seamless maintenance through proactive reporting of issues, thereby minimizing downtime. Thanks to all these developments, candy machines are no longer mere dispensers —they are now fairly intelligent systems that enhance interaction and efficiency. All things considered, technology continues to shape and reshape the role of candy machines in this ever-changing industry.

Final Thoughts on Trends in Gummy Ball Machine

In my opinion, gummy ball machines stand as one of the easiest ideas that innovation and technology could transform into dynamic and engaging systems. Transitioning from a traditional dispenser to an IoT-enabled smart device demonstrates their ability to cater to consumer needs and adapt their methods according to industry demand. These machines have transcended the world of mere vending by integrating with the contemporary tech market, whether through cashless payments, interactive displays, or data-driven replenishment and inventory control.

I feel that the center of these enhancements lies in the enhancement of UX. By analyzing consumer preferences and streamlining the machine’s operations, the business can not only ensure it works optimally but also encourage consumers to interact with it. These trends have not decelerated, yet with advances in AI and robotics, systems ranging from predictive maintenance to audience-specific promotions could become standard features.

Thus, gummy ball machines are proving a veritable canvas for sottogenesis: even selling and buying a bit of candy for oneself can be considered a major innovation. I think this trend spells some great areas where businesses and consumers join hands by way of nostalgia fused with state-of-the-art technology in a challenge that is keeping up with an ever-changing industry.

Reference Sources

-

The Evolution of Gummy Production Technology

This article discusses how automated gummy-making machines have revolutionized production, enabling large-scale manufacturing. -

Innovations in Gummy Counting Machine Technology

Highlights advancements in gummy counting machines, including the use of advanced sensors and computer vision systems. -

The Ultimate Guide to Choosing the Best Gummy Bear Machine

Explores recent innovations like programmable logic controllers (PLC) in gummy manufacturing machines. -

Eliane Gao | The Gummy Candy Machine

A brief overview of high-efficiency gummy candy machines designed for low energy consumption and high yield. -

Electronic Bulk Vending Machines

Features innovative vending machines, including a giant gumball machine capable of holding 50,000 gumballs.

Frequently Asked Questions (FAQs)

What Is a Gummy Ball Machine?

This device distributes colorful gummy balls, often in commercial settings, primarily for entertainment. In many ways, they operate similarly to gumball machines wherein a user inserts a coin or some sort of token and out comes a treat. The gummy balls, as well as some types of candy, come in various flavors and colors that attract children and adults alike. Some machines can be adjusted to accommodate varying sizes of candy balls, providing them with extra utility. These machines come in all styles, basically from the traditional to modern designs that even incorporate digital displays. This presents a wide range of opportunities for candy stores, parties, or simply enjoying fun with kids.

How to Stock a Gummy Ball Machine?

To stock a gummy ball machine, one must first ensure an ample supply of gummy balls in several colors and flavors. The front panel must be removed to access the storage compartment, which should be filled with many gummy balls distributed evenly for optimal dispensing. It is essential to understand the machine’s capacity for candy; overfilling can cause jams. Stock levels must be checked regularly, especially in high-traffic areas. Maintaining a variety of gummy balls will also favor sales, as customers have different preferences regarding flavor.

What Benefits Does Using a Gummy Ball Machine Offer?

There are multiple advantages to setting up a gummy ball machine. One advantage comprises attracting consumers with its colorful and interactive display. These machines offer a gripping and entertaining novel way to enjoy a fine sugary treat. In this respect, the gummy ball machine is well-suited for events, social gatherings, and retail settings. Yet, it is also a marketing tool with a draw effect as the colorful gummy balls are an eye-appealing sight that entices customers. The candy setup can be adjusted accordingly to release multiple types of candy balls, thereby accommodating differing preferences. Moreover, the value of such machines lies in their low maintenance requirements, the infinite array of possible placements, and thus their suitability in any business setup.

Where can you find stock photo images of the gummy ball machine?

Stock photographs of gummy ball machines can be accessed on various stock image websites specializing in commercial and product photography. Select crisp images that showcase the filling process of these machines, featuring hundreds of colorful gummy balls from various angles and styles. Some sites also feature stock images of gummy balls in action, which could be perfect for promotional shots. Additionally, there is a general marketing advantage to using these images on social media or websites. Always check that you have the correct license to use any photos you choose to avoid copyright breaches. An exquisite selection of images can lift your brand visually.

What would the Price Range of Gummy Ball Machines Be?

The prices of gumball machines are known to vary significantly depending on size, function, and brand. Simple gumball machines are attractive, price-wise, for personal use or small business ventures. Larger commercial-size gumball machines with advanced features, such as adjustable candy-only dispensers, are more expensive. When calculating prices, return on investment becomes a key factor to consider, especially for businesses. Also, keep an eye out for promotions or discounts on bulk purchases, which can be a great way to find a bargain. Investing in a high-quality machine proves to be beneficial for customer satisfaction and, ultimately, sales conversion.

What Types of Gummy Ball Machines Do They Dispense?

A variety of gummy balls can be dispensed by these machines, ranging from traditional gummy candies and bubble gum balls to those toy capsules with small surprise items. Many of these machines are designed to accommodate different sizes and types, allowing for a wider selection of treats. Consider, for example, the usual choices: rainbow gummy bears, sour gummy balls, and even occasion-themed candies. The various types of candy balls can cater to a customer’s palate and, in a way, enhance the overall user experience. It also becomes exciting to mix and match flavors and colors in the dispensing process.

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.