You have found the correct recipe which produces fluffy biscuits...

Read MoreExploring the Latest Innovations in Gummy Bear Maker Machine Technology

Understanding Gummy Candy Maker Machines

What is a Gummy Candy Maker?

A gummy candy maker is a specialized machine that facilitates the precise manufacture of gummy candies with accuracy, efficiency, and scalability. These sophisticated machines undertake various candy-making processes, including:

- Mixing – Combining ingredients in precise ratios

- Heating – Achieving optimal temperature for consistency

- Molding – Creating uniform shapes and sizes

- Cooling – Proper solidification process

- Demolding – Safe removal from molds

Key Benefits: Automation of all these steps results in a drastic reduction in production time and labor costs while maintaining consistency in taste, texture, and appearance.

This machinery is available in various production capacities, ranging from small-scale units for boutique production to industrial-grade machines capable of producing thousands of gummy candies per hour.

Temperature and Ingredient Control

In controlling temperature and ingredient ratios lies one of the primary functions of a gummy candy maker. The proper configuration of times and temperatures prevents a gummy from becoming either too soft or too hard, maintaining the soft chewiness that defines quality gummy candies.

Modern-day machines typically come with programmed control systems, allowing manufacturers to modify recipes for producing various types of gummies with changes in:

- Shape variations

- Flavor profiles

- Color combinations

- Addition of vitamins or supplements

Environmental Sustainability

An emphasis is put on being green, with some gummy candy machines designed with an environmentally friendly approach. These eco-conscious features include:

- Prevention of waste through precise dosing systems

- Lowering energy consumption

- Clean-in-place automatic cleaning (CIP) systems that save water

- Minimal ingredient loss capabilities

How Gummy Maker Machines Work

Gummy-making machines feature a set of sophisticated stages that ensure accuracy and efficiency in delivering high-quality confections:

| Stage | Process | Key Features |

|---|---|---|

| 1. Ingredient Mixing | Gelatin, sweeteners, flavorings, and colorants are measured and added in specific proportions | Precise proportioning, automated controls |

| 2. Heating | Mixture is heated to correct temperature for consistency and uniformity | Temperature regulation, smooth texture achievement |

| 3. Molding | Mixture transported to molding section using depositor technology | Accurate processing, minimal waste, consistent sizing |

| 4. Cooling | Deposits solidify and take final recognizable form | Controlled cooling environment |

| 5. Finishing | Demolding, oiling, coating, and customization options | Texture enhancement, prevent sticking |

| 6. Packaging | Sorting, packing, and distribution preparation | Quality control, efficient distribution |

Types of Gummy Bear Maker Machines

Modern gummy bear maker machines come in a variety of types, each designed to meet specific production needs and scales:

Small-Scale Gummy Bear Machines

- Target Users: Home-style operations and artisanal producers

- Features: Compact, cost-effective, temperature controls

- Benefits: Ideal for low-volume production runs, limited kitchen space

- Quality: Unique molding techniques ensure consistency

Medium-Sized Machines

- Description: Intermediate machines balancing production capacity and automation

- Technology: Higher-end mixing, deposition, and cooling technologies

- Advantages: Faster production while maintaining quality and operational efficiency

- Target: Companies seeking to increase output

Fully Automated Gummy Bear Production Lines

- Scope: Large-scale manufacturers, complete automation from mixing to packaging

- Technology: Intelligent control mechanisms, data analytics, robotics

- Features: Multi-zone temperature controls, real-time monitoring

- Capabilities: Support for organic options and sugar-free versions

3D Gummy Printers

Innovation Alert: These cutting-edge machines create intricate designs and custom shapes using precise extrusion and layering principles, significantly expanding possibilities for unique gummy products.

- Technology: Precise extrusion and layering principle

- Applications: Custom confectionery sector

- Status: Emerging technology gaining momentum

High-Capacity Depositing Machines

- Purpose: Fast-paced production of large quantities

- Capability: Deposit various shapes simultaneously

- Features: Sophisticated depositing mechanisms for exact portion control

- Target Market: Mass market manufacturers

Key Features of Electric Giant Gummy Candy Makers

Capacity and Production Speed

| Production Level | Capacity Range | Key Benefits |

|---|---|---|

| Standard Industrial | Up to 10,000 pieces per hour | Meet high consumer demand |

| Advanced Systems | Varies by complexity and size | Precision engineering, automated stages |

| Premium Lines | Scalable based on requirements | Uniform texture, harsh environment operation |

User Friendliness and Setup

Modern gummy candy makers are configured to aid operators with:

- Intuitive Interface: Touch-screen controls and automated calibration

- Easy Setup: Step-by-step guides minimize downtime

- Modular Design: Easy assembly, disassembly, and cleaning

- Compact Design: Ergonomically adapted for any facility type

- Self-Diagnostics: Automatic maintenance notifications

- Safety Features: Automatic shutdown and overload protection

Cleaning and Maintenance Considerations

Proper cleaning and maintenance are prerequisites for ensuring:

- Long-term performance

- Food safety compliance

- Regulatory adherence

Modern Cleaning Features

- CIP (Clean-in-Place) Systems: Minimize manual work, ensure better hygiene

- Modular Design: Improved accessibility for cleaning

- Standards Compliance: FDA and ISO adherence

- Automated Sanitization: Complete internal component cleaning without disassembly

Innovative Technologies in Gummy Candy Manufacturing

Advanced Gummy Candy Mixers

Modern mixers are transforming production by combining precision and efficiency:

| Feature | Technology | Benefit |

|---|---|---|

| Automatic Controls | Programmable mixing parameters | Reduced human error |

| Variable Speeds | Adjustable mixing intensity | Optimal ingredient blending |

| Temperature Regulation | Precise heat control | Consistent texture and quality |

| Data Tracking | Real-time monitoring | Performance optimization |

| Energy Efficiency | Sustainable design | Cost reduction, environmental compliance |

Enhancement of Infusion Flavor Techniques

Innovative infusion techniques have revolutionized flavor incorporation:

Vacuum Infusion

- Air removal from gummy matrix

- Deep flavor penetration

- Balanced and consistent taste experience

Encapsulation Technology

- Flavored compounds coated with protective layers

- Controlled release during chewing or dissolving

- Enhanced flavor delivery

Temperature-Controlled Systems

- Preserve delicate flavoring agents

- Prevent degradation of natural extracts

- Maintain product appeal

Emulsion Techniques

- Incorporate oil-based flavors into water-based mixtures

- Seamless blending without texture interference

- Enhanced flavor variety

Smart Technology for Candy-Making Machines

Industry 4.0 Integration: The candy-making industry has undergone a modern era of advancements, enabling greater efficiency, precision, and quality control through smart technology implementation.

IoT-Based Systems

- Real-time Communication: Machines share production process information

- Precision Monitoring: Temperature, mixing speeds, ingredient ratios

- Waste Minimization: Accurate measurements and consistent products

- Anomaly Detection: Immediate alerts for potential issues

AI-Powered Automation

- Process Optimization: Historical data analysis for best practices

- Demand Forecasting: Predictive operations adjustment

- Energy Conservation: Sustainable resource management

- Predictive Maintenance: Prevent machinery breakdown

Quality Assurance Methods

- High-Resolution Cameras: Product image recording and analysis

- Advanced Sensors: Shape, size, and color irregularity detection

- Automated Quality Control: Only top-grade products reach consumers

DIY Gummy Bear Making Kits

Basic Equipment for Making Gummies at Home

Making gummy bears at home requires the right tools for professional-level results:

| Equipment | Purpose | Key Features |

|---|---|---|

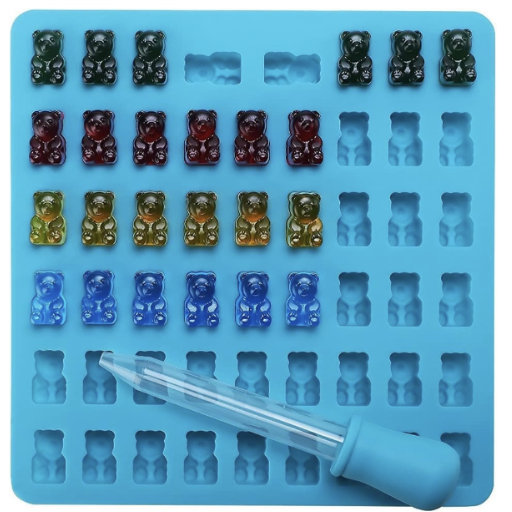

| Silicone Gummy Molds | Shape creation | Non-stick, flexible, easy to clean |

| Droppers or Piping Bags | Precision filling | Prevent spilling, ensure even portions |

| Measuring Cups and Spoons | Accurate measurements | Consistent texture and taste |

| Digital Kitchen Scale | Precise ingredient ratios | Better recipe control |

| Small Saucepan | Even heating | Non-stick or heavy-bottom preferred |

| Mixing Bowls and Whisks | Ingredient mixing | Heat-resistant, smooth texture achievement |

| Candy Thermometer | Temperature monitoring | Consistency assurance |

| Storage Containers | Freshness maintenance | BPA-free, food-grade materials |

Popular Gummy Bear Molds and Designs

The right mold ensures professional-looking results:

Material Considerations

- Silicone Molds: Flexible, durable, easy to work with

- Food-Grade Quality: Non-toxic, heat-resistant, dishwasher-safe

- Easy Release: Prevents cracking or shape loss

Popular Designs

- Traditional Gummy Bear: 50-100 cavities per tray

- Large Designs: Special occasions and decorations

- Themed Molds: Seasonal and fun designs

- Complete Kits: Include droppers for easy filling

Homemade Gummy Candy Recipes

Creating homemade gummy candies allows for complete customization of flavors, colors, and textures:

Basic Recipe Components

- Gelatin (or agar-agar for vegetarian option)

- Fruit juice or pureed fruits

- Sweeteners (honey, sugar, maple syrup)

- Flavor extracts

- Natural coloring agents

Popular Flavor Combinations

- Tropical: Mango-based gummies

- Mixed Berry: Strawberries and blueberries

- Citrus: Lime or orange juice

- Enhanced: Vitamin C powder or collagen

Process Overview

- Mix gelatin with warm fruit juice over low heat

- Stir until powder completely dissolves

- Pour solution into molds

- Refrigerate for 2-3 hours until set

- Store in airtight containers for freshness

Comparing Gummy Candy Machines for Different Needs

Portable vs. Commercial Gummy Bear Makers

| Feature | Portable Makers | Commercial Makers |

|---|---|---|

| Capacity | Small-scale, personal use | High-volume production |

| Size | Compact, lightweight | Larger footprint required |

| Investment | Cost-effective, affordable | Substantial initial investment |

| Features | Simple temperature control | Full automation, advanced controls |

| Learning Curve | Minimal know-how required | Professional training beneficial |

| Best For | Home use, small batches | Business operations, bulk production |

Essential Features to Look for in a Gummy Machine

Capacity Requirements

- Home Use: Small-capacity models for personal projects

- Commercial Use: Extensive output capability for high demand

- Scalability: Ability to meet growing production needs

Ease of Use

- Intuitive Controls: User-friendly interface

- Easy Assembly: Quick setup and breakdown

- Simple Cleaning: Minimal maintenance requirements

- Automation Features: Temperature control, preset programs

Durability and Quality

- High-Quality Materials: Stainless steel construction preferred

- Heavy-Use Endurance: Built to last under continuous operation

- Warranty Coverage: Comprehensive protection for investment

- Long-Term Value: Quality construction prevents frequent replacement

Cost Considerations and Budget Options

Investment Strategy: Balance initial budget against desired features while considering long-term value and operational costs.

Budget Planning Factors

- Initial Investment: Machine purchase price

- Operating Costs: Energy consumption, maintenance

- Replacement Frequency: Durability impact on long-term costs

- Warranty and Support: Protection against unexpected expenses

Value Optimization

- Quality vs. Price: Higher initial investment for better durability

- Financing Options: Payment plans for higher-end models

- Promotional Opportunities: Special offers and discounts

- ROI Consideration: Business growth potential

Reference Sources

-

Launching a Gummy Bears with the Gummy Production Line

Discusses dual-hopper systems for two-color or dual-flavor gummies, showcasing versatility in production. -

2025 Top Gummy Candy Machine for Efficient Production

Highlights precision engineering and innovative manufacturing technology in gummy-making machines. -

The Latest Innovations in Gummy Bear Making Machines

Covers advancements like automated mixing, improved cooking processes, and high-speed molding. -

Gummy Maker – Magical Brands

Features unique designs, including stainless steel mixers and innovative control panels. -

Everything You Need to Know About Purchasing a Gummy Machine

Explains how automatic gummy-making machines enhance flexibility and automate critical processes.

Frequently Asked Questions (FAQs)

What is a gummy maker machine?

A gummy maker machine is a specialized manufacturing unit designed for producing gummy candies, particularly gummy bears. These machines feature depositors for precise pouring, flavor and color addition capabilities, and often include silicone molds for easy cleaning and reuse.

How do I make gummy candy using this machine?

The process typically involves:

- Create gummy mixture by melting gelatin and sugar

- Pour mixture into machine’s depositor or dropper

- Dispense onto silicone molds

- Allow mixture to set before removing from molds

- Use candy dispenser if available for easy serving

What are the advantages of DIY gummy makers?

DIY gummy makers offer complete customization of flavors and ingredients, allowing you to create homemade confections tailored to your taste. Benefits include ingredient control, family-friendly activities, and the ability to add nutraceuticals like vitamins and collagen.

What types of molds work best for gummy candies?

Silicone molds are preferred due to their non-stick nature and flexibility, allowing easy removal without damaging candies. Look for food-grade, dishwasher-safe molds in various sizes and shapes to add creativity to your gummy production.

Are gummy bear maker machines safe to use?

Yes, when following guidelines properly. Look for machines made from food-grade materials that are dishwasher safe. Many models include safety features like overheating protection and secure melt pots. Always supervise children when using machines with heating elements.

What flavors can be added to gummy candy?

Gummy candies offer extensive flavor possibilities including fruit juices, extracts, and oils. Many machines feature infusers for atmospheric essence infusion. Popular options include natural fruit flavors, and you can experiment with combinations to create unique taste profiles.

Related Posts

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.