You have found the correct recipe which produces fluffy biscuits...

Read MoreHow a Biscuit Crusher Machine Enhances Efficiency in Large-Scale Food Production

In large-scale food industries, time is of essence unfortunately. Scope for manufacturers is always being extended by apparition of tools that make manufacturing a smooth sail, reduce waste, and give best output. Amongst the many, the biscuit crusher machine has proved to be a revolution in this field. It is meant to ease and optimize the biscuit by-products handling process and thus convert them into useful resources; otherwise, those would have been disposed of. But how does the machine operate? And always kept as a secondary concern is the big question of whether it contributes to efficiency enhancement. This blog sheds light on processes involved in high-end biscuit crusher machines, how it affects production costs and enhancement of sustainability.

Understanding the Biscuit Crusher Machine

What is a Biscuit Crusher Machine?

This type of crusher machine is simply a specific piece of equipment designed for breaking biscuits, cookies, and related baked goods into smaller, uniform pieces or crumbs. Numerous machines like these are utilized within the food manufacturing industry to recycle surplus or damaged biscuits or biscuits not meeting specifications; such machines convert the biscuits into materials that can then be reworked further for distribution or incorporated as ingredients for other products. Using advanced crushing mechanisms, such as rotating blades or rollers, the biscuit crusher machine is capable of producing crumbs of uniform particle size very precisely according to any particular size requirement in a production program. This step thus creates an effective process that fits well with modern industry trends in waste minimization and sustainability with manufacturers benefiting cost-wise.

Key Features of Biscuit Crushing Machines

- High Efficiency and Consistency

Biscuit crushing machines are designed to deliver efficient processing with uniform particle sizes. This guarantees that the crushed material meets exact production standards, ensuring a consistent quality in downstream applications. - Durable Construction

Built with robust materials such as stainless steel, these machines provide excellent durability, corrosion resistance, and long operational lifespans even under continuous industrial usage. - Adjustable Settings

Many modern biscuit crushers come equipped with adjustable mechanisms to alter crushing intensity and particle size. This flexibility caters to different manufacturing needs, enhancing machine versatility. - Hygienic Processing

Adhering to food safety standards, these machines are designed for easy cleaning and maintenance to prevent contamination. Smooth surfaces and detachable components help maintain a high level of hygiene. - Energy Efficiency

Advanced models focus on reducing power consumption while maintaining optimal performance. Energy-efficient operations help manufacturers cut costs and meet sustainability goals. - Automation and Smart Integration

With options for full or semi-automation, some machines integrate with smart control systems for improved monitoring and operational adjustments. This reduces human intervention and enhances productivity. - Compact Design

Despite their powerful performance, many models feature compact footprints, making them suitable for facilities with limited space. - Customizable Options

Manufacturers often offer customization to match specific production requirements, such as capacity upgrades or specialized crushing mechanisms, ensuring tailored solutions for various industries.

These features collectively make biscuit crushing machines an essential asset for food production and recycling processes, aligning with modern manufacturing trends.

Types of Biscuit Grinder Machines Available

Hammer Mill Grinders

The machine uses high-speed hammers that rotate for crushing biscuits into either fine or coarse particles. In large-scale applications, hammer mills are preferred because of their efficiency and ruggedness. The particle size can be easily adjusted by these mills, and they are essentially suited for continuous production lines.

Roller Grinders

Roller grinders crush biscuits through the action of parallel rollers rotating against each other and against the rolls. These machines are more useful when a manufacturer requires uniform particle size or a product with a smooth, fine texture. Such grinder systems find applicability in the bakery and confectionery fields.

Pin Mill Grinders

A pin mill uses closely spaced pins to break the biscuits into fine powders. They are most suitable for ultra-fine grinding applications, such as fine biscuit flours or other fine products.

Universal Grinders

The universal grinders are quite versatile and capable of handling multiple sorts of biscuits of multiple textures. They have provisions for variable speed and interchangeable parts for grinding so as to serve many needs from crushing coarsely to grinding superfine.

Disc Grinders

Be it with discs aligned on a vertical plane or on a horizontal one, these grinders crush the biscuit using shear and compression forces. Disc grinders are known for their energy efficiency, being able to handle and process both soft and hard biscuit types.

Specialized Compact Grinders

Designed for small-scale or niche operations, compact grinders are modern machines that save space while maintaining performance. These are useful for R&D work or small setups with limited production capacities.

Selecting the right type of biscuit grinder depends on factors like production scale, desired particle size, and specific industry requirements, ensuring an optimal balance between functionality and cost-effectiveness.

The Role of Biscuit Grinding Machines in Production Lines

How Biscuit Machines Improve Production Efficiency

The grinding machines boost production efficiency by laying the foundation upon which manual labor is reduced to minimal levels. These machines employ certain apparatuses to maintain high precision in the grinding process so that particles of a particular size can be produced.freeze The desired size is elemental for associating with product quality. Industry-designated means of working awry may hence put downtime to a minimum and, as a consequence, maximize throughput. So, in other words, faster outputs in production lines do not come at the expense of standards by using an automated process for grinding.

Modern machines also come equipped with energy-efficient motors, so less power must be consumed, and operational costs are kept down with time. These grinder machines have adjustable features to optimize efficiency based on the variations of biscuit formulations. Operators will be detecting problems and resolving them in real time so any delays are prevented, and operations flow on smoothly.

Research in industrial manufacturing shows how investing in automatic grinding solutions could elevate the efficiency of production by up to 30%, marking them as must-haves in modern competitive, sustainable production lines.

Integration of Biscuit Crusher Machines in Factory Settings

Biscuit crushing machines are regarded as an essential machine in modern factories. This is because the need for these machines arose during the production on a commercial scale and must suffice the demand. These machines essentially do the bulk of the biscuit crushing while maintaining uniformity of particle sizes that go into various manufacturing processes such as crumb coatings or fillers or rework products. Featuring state-of-the-art technologies-a biscuit crusher with adjustable crushing mechanisms and automatic feeding operation ensures high precision and consistency with its working.

One of the major advantages of such machines lies in its ability to recycle any off-specification goods into raw material, hence working toward sustainability in manufacturing. Many are also equipped with interfaces and telemetry capabilities, which operators use to monitor and adjust machinery processes easily. Research shows that factories empowered by such machines minimize material waste by as much as 25% and gain tremendously in productivity-enhancing effects, thereby cementing their place in the highly competitive arena of production.

Customizing Your Biscuit Production Line with Crusher Machines

Crusher machines find principal use in modern biscuit production lines and assure that texture and quality of the final product stand consistent. These crusher machines chop down the raw materials-peaks as in excess dough, biscuit fragments-and recycle them back into usable forms without any compromise on quality. Through the incorporation of crusher machines into the production line, manufacturers augment the management on waste, reduce material costs, and reach the sustainability goals. The latest versions have their settings customizable, so crushing levels may be adjusted to lock onto the precise needs of the production process.

For instance, a high-efficiency crusher could enhance production efficiency: some factories cite improvements of 20 to 30 percent in resource utilization. Newer models may also require energy consumption and little maintenance, thus providing quite substantial long-term cost savings. Engineering these machines according to your particular biscuit making process would make the operations more streamlined with a considerable operational advantage of increased productivity and profitability.

Working Principles of Biscuit Crushing Machines

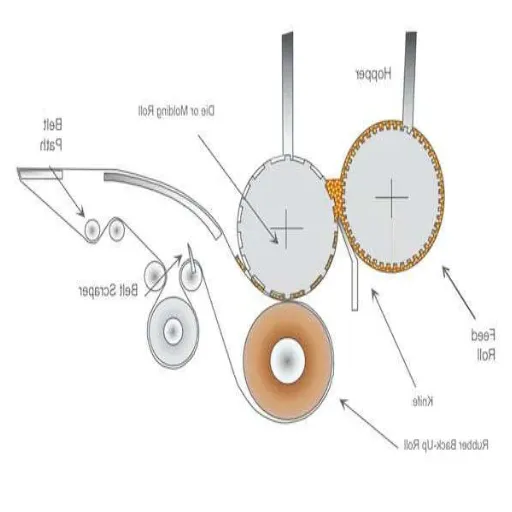

Mechanisms Behind Biscuit Grinding and Crushing

Biscuit crushing machines combine high-level mechanical systems for precise grinding and size reduction. In general, these machines use a couple of rollers or grinding discs that apply pressure to crush biscuits into smaller particles or fine crumbs. If the design permits, adjustment settings may allow the manufacturer to change output granularity depending on the product’s requirements, be it for further reprocessing or incorporation into another food product.

Energy-saving and high-throughput machines are placed, thanks to the modern advancements in motors and crushing mechanisms. For example, vibration damping parts are installed in some machines to enhance the stability of these crushers and maintain uniform particle size. When it comes to operation, the actuators and sensors will control the process across the whole plant, ensuring that production is nonstop, and downtime and waste are kept to a bare minimum. Stainless steel is adopted for hygiene reasons, yet it is also durable, which is textbook for food production.

Advantages of Automatic Biscuit Crushing Machines

Automatic biscuit-crushing machines have diverse utilities, especially when set up for massive industrial and food productions. These machines enhance work efficacy by cutting down manual processing times co-equally with work effort. Crushing at high speed lessens the variation in output due to the particle size that is essential for downstream processes such as baking or mixing.

Another essential benefit is precision and consistency. Designed for uniformity, these machines enhance the product quality and generate less waste. Their automation systems and sensors monitor crucial parameters like pressure or temperature and hence guarantee their operation at optimal level with the least possibility of human intervention.

They can also be made strong by construction and require durability from materials such as stainless steel while fulfilling the hygiene standards of the food industry. Energy efficiency has been imparted into the modern machines, some with the ability to reduce power consumption without affecting performance. Having the intermittent operation capacity, the automatic biscuit crushing machines form scalable and cost-efficient solutions coupled with manufacturers and industries to meet a growing demand in the marketplace.

Understanding Coarse Crusher Machines and Their Uses

One of the coarser types of crushing machines is made available to grind big chunks of material into more manageable pieces. Belonging to chemical, pharmaceutical, food, and mining industries, those machines are made to treat somewhat tough or even bulky materials and thereby making the processing easier. Usually fitting coarse crushing machines with sturdy blades or hammers, modes of treatment may include anything from spices to minerals, grains to plastics.

The latest coarse crushing innovations focus on strength and precision, employing materials that resist wear so the machines might enjoy long service lives. Of course, newer models also look at the power reduction side and guard against noise reduction in order to meet sustainable and human-friendly operations. Further versatility is added to these machines by enabling users to set different output particle sizes to suit various applications. For instance, in the food industry, the coarse crusher may be efficiently used for pre-processing major raw materials like sugar or grains into a final stage without impairing the product quality.

Benefits of Using Stainless Steel in Biscuit Machines

Why Stainless Steel is Preferred for Biscuit Crusher Machines

Stainless steel is regarded as the best material for biscuit crusher machines due to its durability, hygiene, and performance. The machinery is further provided with corrosion resistance so that it remains strong even when subjected to humid or high moisture environments encountered in food processing plants. Corrosion resistance also gives the advantage of extending the lifespan of the machine and cutting down the maintenance costs with the passage of time.

Also, the fact that stainless steel was and remains non-porous made it easy to clean and sterilize, really crucial in food safety standards. There are fewer chances for contaminants and bacteria to lay on frets against the stainless steel surface, and that reduces the incidence of foodborne illnesses. The next thing is that it is strong and resilient and will face the wear and tear of continuous crushing and grinding, hence ensuring consistent performance with minimal downtime.

Stainless steel can also claim to have beauty as its other key advantage. The polished finish is in tune with the professional standards of food processing machinery of today, hence giving a look of cleanliness and quality. These attributes together make stainless steel an essential choice for biscuit crusher machines, thereby aiding efficiency, safety, and reliability down production lines.

Maintenance and Hygiene Considerations for Stainless Steel Machines

In industrial settings, proper maintenance and hygiene are very important for clients in industries to prolong the lifespan of stainless steel machinery and ensure their safe operation. Hence, in order to maintain acceptable standards of performance and sanitation, a regular cleaning schedule should be kept to prevent the build-up of residues. For best performance and consolidation, cleaning agents of an abrasive variety and those that contain chloride should never be applied as this would lead to pitting or corrosion of the stainless steel surface.

The studies have shown that following a cleaning protocol after each production cycle greatly minimizes the risk of contamination and hence maintains compliance with food safety standards. Regular inspection for wear in general, such as scratches and dents, is vital since bacteria may get harbored within these imperfections or the very structure of the machine may get compromised by them. Sealing the food-contact areas with food-grade lubricants is also critical from the perspective of smooth movement and hygiene regulations.

Another option to safeguard stainless steel protection is passivation of the surface. This treatment increases corrosion resistance in very aggressive processing environments. Proper storage of the equipment in conditions with low humidity and away from reactive chemicals is another way to protect it. Combining regular maintenance with such preventive measures helps to protect stainless steel machines so they keep their original looks while the best functioning of the product is assured.

Durability and Longevity of Stainless Steel Biscuit Grinding Machines

The integration of higher manufacturing technology has boosted the life and durability of the stainless biscuit grinding machines. Modern machines have grinding components manufactured with precision, enhanced by CNC systems, ensuring a consistent quality of output and less wear on the internal components. More importantly, owing to the optimization of corrosion resistance of high-grade stainless steels like 316L or duplex grades, it is becoming increasingly common to employ these in construction, offering even better performance in high humidity or exposure to food-grade cleaning agents environment.

For example, new finishes and coatings that are designed to be very smooth reduce friction and stickiness during grinding operations, thereby protecting the machinery and helping to improve operational efficiency. Industrial food processing equipment studies have shown that with these advanced features, machines tend to last 20 percent longer than those using old technologies. On the other hand, these modern systems are often built in with predictive maintenance notifications that track wear on critical components and alert technicians to perform replacement work before unexpected downtime actually occurs. Thus, by using these advanced technologies, businesses can help yield cost efficiency and long-term reliability in their biscuit production operations.

Choosing the Right Biscuit Crusher Machine for Your Needs

Factors to Consider When Selecting a Biscuit Crusher

Choosing the right biscuit crusher machine is a critical decision that impacts production efficiency, cost management, and product quality. To ensure you make the best choice, consider the following factors:

- Production Capacity

Evaluate the crusher’s throughput capacity to align with your production demands. Machines with higher capacities are ideal for large-scale operations, while smaller systems are best suited for niche or small-batch manufacturing. - Material Compatibility

Ensure the machine is compatible with the types of biscuits you process. Some biscuit crushers are designed for soft, crumbly biscuits, while others can handle harder or coated varieties without compromising product quality. - Durability and Maintenance

Look for machines built with robust materials and high-quality components, ensuring long-term durability. Additionally, opt for models that are easy to clean and maintain, with accessible parts to reduce downtime during servicing. - Automation Features

Modern biscuit crusher machines often come equipped with automation features like programmable settings, automatic feeding mechanisms, and real-time monitoring. These functionalities enhance operational efficiency and minimize manual intervention. - Energy Efficiency

Energy-efficient models can significantly lower operational costs while maintaining high performance. Check the energy consumption ratings and consider systems that use advanced technology to optimize power usage. - Noise Levels

Consider noise levels, especially for facilities located in urban or noise-sensitive areas. Machines with noise reduction systems contribute to maintaining a quieter and more worker-friendly production environment. - Cost Efficiency

Assess the initial investment, operational costs, and long-term value. While cheaper machines may seem appealing, investing in a high-quality system often pays off through reliability, efficiency, and reduced maintenance expenses. - Safety Standards

Safety is paramount in industrial operations. Ensure the crusher adheres to industry safety standards, featuring guards, emergency shut-off systems, and user-friendly controls to protect operators. - Scalability

If you anticipate scaling your production in the future, choose a machine that can accommodate increased requirements or be easily upgraded. This prevents the need for costly replacements later. - Vendor Support and Warranty

Select a supplier with strong customer support, extensive warranties, and readily available spare parts. Reliable post-purchase service ensures continuity in case of technical issues.

By carefully considering these factors, you can choose a biscuit crusher machine that meets your production goals, aligns with your budget, and supports the long-term success of your operations.

Comparing Different Biscuit Crushing Machines in the Market

From there, I consider a machine’s performance and efficiency. Higher capacities unfortunately come with higher price in crushing equipment, but for operations with very high demand, the ability to crush greater quantities of biscuits in less time is an essential factor. I look at the adjustment range of the machine for different biscuit sizes, shapes, and consistencies. Ensuring some flexibility on this front would mean that the machine can work across various product lines without compromising either quality or consistency.

Further important aspects that I evaluate include build quality and durability of the equipment. Stainless steel machines of food-grade quality as machines are more hygienic; however, such machines can also undergo much wear and tear, reducing their life span. Maintenance is a condition that I put into consideration. There are machines with parts designed to be easy to clean and maintain and avoid long downtime during service. Another aspect I categorize in the best equipments is energy efficiency, which brings down the operational cost in tandem with performance.

Further important aspects that I evaluate include build quality and durability of the equipment. Stainless steel machines of food-grade quality as machines are more hygienic; however, such machines can also undergo much wear and tear, reducing their life span. Maintenance is a condition that I put into consideration. There are machines with parts designed to be easy to clean and maintain and avoid long downtime during service. Another aspect I categorize in the best equipments is energy efficiency, which brings down the operational cost in tandem with performance.

Top Manufacturers of Biscuit Grinding and Crushing Machines

Searching through the latest trade information, I found several manufacturers branded as top producers of biscuit grinding and crushing machines. Their names were considered for their machines’ durability, innovation, and design catering to different production needs.

Bühler Group

This is another situation: a brand known all over the world for precision engineering and cutting-edge technology. A grinding and crushing machine should be efficient to operate manually; this puts in automated controls and a high-capacity output generally useful in operations where continuous and scalable output are required. Bühler machines have often been praised for their reliability and long-term durability, hence remaining the best choice for large-scale manufacturers.

GEA Group

Specializing in cutting-edge food processing equipment, the GEA biscuit grinding machines are appreciated by food production plants that strongly emphasize both quality and hygiene standards in their design, energy efficiency, and maintenance requirements. The solutions accommodate businesses of diverse scales and allow flexibility without compromising on performance.

Hosokawa Micron Group

It is a real standout for particle size reduction technology with its innovativeness. The machines are specifically crafted with precision crushing and grinding adjustment for varying biscuit textures. Known to combine rugged engineering with cutting-edge automation, Hosokawa equips manufacturers that want flexibility and process optimization.

By considering manufacturers like these and evaluating their machines based on certain production needs, costs, and the reliability of the machine in the long run, my decision will be made accordingly, and so will the operational goals.

Reference Sources

- How Does a Biscuit Factory Machine Contribute to Large-Scale Production

This article discusses the role of biscuit factory machines in modern production, focusing on efficiency and quality. - Industrial Biscuit Crusher Machine Multipurpose

Details the features and benefits of industrial biscuit crusher machines, including their efficiency and food-grade materials. - How Biscuit Machinery Innovations Affect the Baking Industry

Explores how innovations in biscuit machinery have improved efficiency and throughput in the baking industry. - How to Crush Biscuits in a Food Processor Machine

Provides insights into the process of crushing biscuits using machinery, highlighting its practicality and efficiency.

Frequently Asked Questions (FAQs)

What is a biscuit crusher machine?

Biscuit Crusher Machine is a unique kind of milling machinery meant for biscuit cookies to fine biscuit crumbs. It is used extensively in food processing factories to foster production line efficiency. Generally, a biscuit crusher machine uses high-grade food materials so that the product remains disinfected and safe for consumption. Since it comes with sturdy construction of stainless steel 304 grade sometimes, it can stand the stress of constant working. It will crush uniformly so that the granules of one size will be produced in the product.

How does the biscuit crushing machine work?

Working of crushing machine for biscuit consists a crushing chamber into which biscuit cookies are fed through the hopper. The machine destroys the biscuit pieces mostly by the speed of its rotation. Coarser and finer crushing of biscuit crumbs can be done, depending upon the fineness desired. The crushing machine is equipped with a powerful motor and has a very efficient design for high crushing efficiency and is the main machine in any snack factory. It is easy to clean, which is crucial for maintaining excellent hygiene standards in food processing.

What are the benefits of using a biscuit grinding machine?

The biscuit grinding machine has numerous advantages such as high efficiency and uniform crushing results. It allows food processing companies to produce biscuit crumbs quickly for various applications, such as toppings or ingredients for other products. The machine can process a huge amount of biscuit cookies and transform them into granules of the chosen fineness. That said, they are engineered to run silently, giving a pleasant working ambiance. These qualities render them downright indispensable in production areas with high demands, considering they can operate non-stop.

Can the biscuit crusher machine customize the crushing size?

There are typically options for crushing size adjustment in many biscuit crusher machines, depending on the production requirements. Operators can use different sieves or adjust the crushing parameters to obtain different levels of fineness for the biscuit crumbs. This is advantageous when the food processor requires specific granule sizes for recipes. Manufacturers customize the crushing process to maintain quality control for their clients’ varied demands. This feature generally adds to the machine’s versatility on the production line.

Is the biscuit crusher machine easy to maintain?

Having said that, biscut crusher machine maintenance was purported to be made easy in it. Constructed from stainless steel 304, it affords high durability and ease of cleaning. The equipment is disassemblable, enabling thorough cleaning, which is a must to avoid any contamination in food processing. Machines may be put through maintenance most easily in accordance with its design, which allows them to operate with maximum efficiency. With proper maintenance, the machines will remain consistent in operation for long enough to become reliable production line aids in biscuit production.

What are the applications of a biscuit crumbs mill?

From the point of food and snack manufacturing, biscuit crumbs mills find a vast range of applications. The crumbs become an ingredient in baking used as toppings, coatings, or fillers in other snackies. They can also be converted into ingredients for some tare: confectionery products, or even dessert bases. Likewise, crumbs that are very versatile are treasured in all kitchens, commercial and industrial ones. Also, with the mill making fine-quality crumbs, the manufacturers retain the very taste and texture of their end products that they want.

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.