You have found the correct recipe which produces fluffy biscuits...

Read MoreHow a Gummy Filling Machine Can Boost Efficiency in Candy Production

Precision, consistency, and efficiency characterize the manufacture of average gummy candies. This is particularly true in an industry where consumer demand is booming and product variety is increasing. They would try to find a delicate balance between the two, taking into account the size of production, which at times proves to be a herculean task. Now, the gummy filling machine has stepped in as the Gleamer to claim the honor of improving processes and streamlining operations in candy production. This review examines the various ways in which the aforementioned guitars have enhanced manufacturers’ efficiency, increased product quality, including waste reduction, thereby steering trends in the candy market. Whatever the size of your market, whether small or large scale, an understanding of what the gummy filling machine carries and for whom will go a long way in reorienting production methods. Keep reading to see how this life-altering technology gives a new face to your candy-making business.

Understanding Gummy Filling Machines

What is a Gummy Filling Machine?

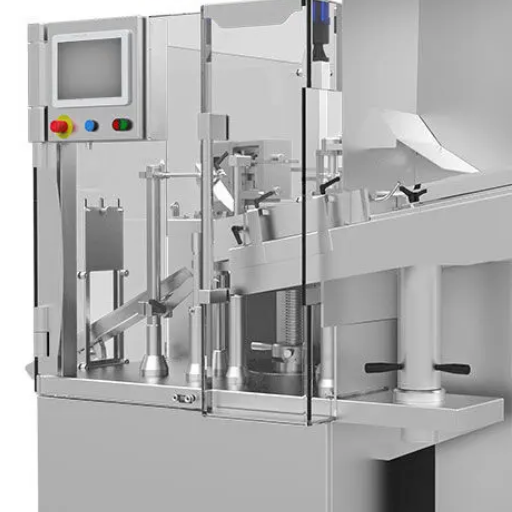

A gummy filling machine is a customized machinery that helps automatize the gummy production process. It fills molds with definite drops of gummy mixture; hence each and every candy is consistent with its size, shape, and flavor. These filling machines use the most accurate dosing systems, allowing them to measure correctly with as little waste as possible or to keep production processes consistently equal wherever possible. Most gummy filling machines also come with temperatures control so that molding and cooling can be done in very specific conditions required to achieve proper texture and finish of the gummies.

A certain source explains that such machines have options for manufacturers to create an endless number of shape, color, and flavor combinations to meet market demand. Multi-layer filling for dual-flavored gummies, inclusions of fruit pieces, or vitamin inclusions may also be present, according to the model. These gummy filling machines enhance new concepts in the confectionary sector by providing fast-paced production through automation and accuracy.

Key Features of Gummy Filling Machines

High Production Efficiency:

Modern gummy filling machines are designed to ensure maximum speed and accuracy, delivering consistent quality with a high volume of output. These machines typically operate through automated systems, filling anywhere between a few hundred and thousands of molds per hour, drastically reducing production time without compromising precision.

Customizable Capabilities:

Various advanced settings are included in gummy filling machines that manufacturers can use to produce gummies in a wide range of shapes, sizes, and flavors. Customization may involve anything from changing the shape of the molds used to finishing a gummy with two different flavors at once, along with precise dosing for vitamins or other functional ingredients.

Precision and Consistency:

Nowadays, the filling system ensures an exact measure is used for each gummy, keeping them uniform in appearance and taste. Precision is even more crucial when it comes to strict quality control measures, especially in nutraceuticals, where dosage is of utmost importance.

Advanced Heating and Cooling Systems:

Integrated heating systems maintain the gummy mixture at the ideal temperatures by ensuring smooth filling and preventing crystallization or separation. When coupled with high-performance cooling solutions, these systems enable fast setting of the gummies to ensure a smooth flow on the lines.

Hygienic Design:

Made entirely of food-grade materials, these gummy-filling machines are designed for easy cleaning and come with CIP (Clean-In-Place) systems, which enable manufacturers to comply with strict hygiene standards, reduce the potential for contamination, and simplify maintenance.

Integration with Modern Technology:

These days, many machines come equipped with digital monitoring and control systems, including touchscreen interfaces and IoT-enabled connectivity, which provide real-time production feedback and troubleshooting, thereby enhancing operational transparency and streamlining the optimization of production workflows.

Energy Efficiency:

Newer models incorporate energy-saving technologies, minimizing power consumption without compromising output. This reduces operational costs and supports the sustainability of the manufacturing sector.

Including such features in gummy filling machines enables companies to streamline their production, maintain high quality standards, and adapt to changing consumer demands in competitive markets.

Types of Gummy Filling Machines Available

Semi-Automatic Gummy Filling Machines:

These machines find utility mainly in small- to medium-scale shops. They afford partial automation under which operators perform some kind of work, like feeding of molds or adjustment of settings. Because these gummy-producing machines can churn out extremely tiny batches of sweets that can be served slightly differently, they have remained ever cheap and flexible. These semi-automatic machines have always been considered to be the easiest to operate, and perhaps are the best way that a manufacturer can phase out a completely manual process.

Fully Automatic Gummy Filling Machines:

Fully automated systems are used for mass production. They simplify everything from dosing to filling, chilling, and molding of the gummies. These machines are comfortable when equipped with features like PLCs, touchscreen interface, and automatic cleaning systems. Fully automatic gummy fillers have very high production rates while maintaining good quality, so they are needed most in the most demanding industrial sectors.

Multi-Head Gummy Filling Machines:

Designed for speed and efficiency, multi-head machines are tailored for working on multiple molds concurrently. It is highly suited for gummy batches having different shapes, sizes, or flavors. The machines purvey dosing systems to have every batch properly and uniformly dosed. This curbs wastage and heightens productivity. Manufacturers with multiple gummy product lines end up being pretty well suited because of their versatility.

Depositing Gummy Filling Machines with R&D Capabilities:

For companies engaging with innovation and new product development, depositing machines with R&D capabilities are a must. These machines offer the whole suite of different gummy formulation’ experiments, such as sugar-free, vitamin-enriched, or functional gummies. More advanced depositing machines ensure precision in filling, even when faced with complicated or delicate formulations, thereby enabling manufacturers to keep pace with changing consumer preferences.

Rotary Gummy Filling Machines:

Quick and compact are just a few words used to describe these systems. Because some manufacturers do not have large factory floors, these systems are a good fit. The machines facilitate circular movement, enabling the quick and even filling of molds. It is primarily found in mammoth-scale industrial settings and is designed to be durable with minimal maintenance. They can produce substantial volumes at the rotary-swimming gummy filling machines without compromising quality.

Manufacturers, by selecting the most suitable type of gummy filling machine, can optimize their production lines, reduce operational costs, and remain competitive in a market driven by speed, innovation, and consumer demand.

The Role of Gummy Filling Machines in Candy Production

Increasing Production with Gummy Filler Machines

The gummy filling machines have brought about a remarkable increase in speed in candy making, with utmost consistency. These modern machines are equipped with advanced technologies, including servo-driven systems and programmable controls, which enable precise dosing and faster cycle times. They have, for example, the power to fill thousands of gummy molds per hour at very high speeds, providing complete satisfaction to meet the increased demand for confectionery products on both ends of the scale, from small and significant operations.

Modern automation has also enabled the integration of industrial gummy filling machines, aligning production processes, minimizing manual intervention, and avoiding downtime. A few other advantages are automated feeding to molds and self-cleaning systems, increasing productivity and achieving high uptime. With such machines, manufacturers can also augment output and maintain control over ingredient ratios to produce uniformly high-quality products at specifications that satisfy governmental and consumer standards.

A step towards accuracy in candy filling

It is increasingly becoming difficult to improve the candy-filling process for manufacturers, as they have to adhere to very stringent quality standards while simultaneously keeping their operational facilities efficient. The present gummy-filling machines incorporate both volumetric and gravimetric dosing technologies in order to produce the volumetric measurement of the ingredients during production. Variation in size, shape, or weight is reduced by these machines, thereby conferring on the end product uniformity that meets both regulatory and consumer standards. The presence of smart sensors and real-time monitoring systems will ensure that any deviation is rectified in real time. Such improvement of accuracy will render cost-draining errors avoidable.

Automation and AI technologies together form an important development in this field. Depending on the type of data collected in production, machines analyze it and decide their own best course of action. Just to name a few, AI algorithms can identify anomalous conditions during filling, adjust equipment in real-time, and predict when maintenance may be required, thereby minimizing or even eliminating disruptions. Another essential element is traceability, maintained through automated ingredient tracking, which food safety regulations require and these methods further help improve consistency in candy filling while concurrently reducing wastage, simplifying the workflow, and maximizing production output, thus assuring a competitive edge for the manufacturers in this harsh industry.

Reducing Waste in Gummy Production

Waste reduction in gummy manufacture constitutes the first step toward sustainability, with operational efficiencies, and at the very least, becoming profitable. New manufacturing sequences utilizing modern technology aim to prevent the overuse of materials. These automated precision measuring systems ensure that raw materials, such as gelatin, flavorings, and sweeteners, are measured strictly to the quantity necessary, thereby minimizing off-spec batches and waste. Excess or leftover materials from manufacturing are also being recycled through closed-loop recycling systems.

They have significantly reduced such figures by the increasing adoption of new manufacturing technologies and real-time monitoring systems in them. Predictive analytics can, for example, identify when a process is likely to become inefficient and wasteful. An optimized mold design ensures that gummy shaping is ideal, reducing cutting and rework.

Over time, investment in green materials and biodegradable packaging has increased, with the aim of complementing conservation measures with waste reduction and conversion. Such activities enhance environmental well-being and are highly esteemed by consumer circles, placing their priorities on responsible production principles. Moreover, minimizing waste in gummy-type production yields significant savings through improved resource management and a more sustainable future for the confectionery industry.

Gummy Packaging Solutions

Choosing the Right Gummy Packaging Machine

Choosing the perfect gummy packaging machine requires careful consideration of factors that weigh on efficiency and quality, as well as production needs. Some of these factors include:

- Production Capacity: How many gummies do you manufacture per day or month? The packaging machine should meet minimum capacity requirements. High-speed machines would handle larger volumes, allowing for a quicker turnaround when fulfilling large-scale production demands.

- Kind of Packaging and Versatility: What type of packaging can the machine offer—pouches, bottles, etc.? A machine with a wide variety of packaging types allows its products to be marketed in multiple ways, thereby staying ahead in the market.

- Material Compatibility: Nowadays, gummy packaging machines can handle a variety of eco-friendly materials, such as biodegradable films and recyclable plastics. Choosing a machine that is compatible with sustainable materials keeps operators on the good side of environmental regulation and meets consumer demand for green practices.

- Automation Degree: The greater efficiency is the outcome of automation. Regarding the degree of automation of a particular machinery, weighing, filling, and sealing are more precise or less so with human intervention, thus increasing error levels and reducing output. Additionally, automated quality testing ensures product consistency.

- Hygiene and Safety Standards: Certifications for food-grade applications and adherence to hygiene standards lay the foundation for gummy production. The machines built with features such as stainless steel components, washdown capabilities, and stringent sanitation procedures eliminate contaminants to uphold product quality and safety.

- Energy Efficiency and Operating Expenses: Check the energy efficiency status and operating cost of the machine. An energy-efficient machine will result in lower utility costs and align well with sustainable manufacturing practices. Thus, any machine that happens to be easy to maintain will come in handy, lowering the cost of operations in the long haul.

- Integration with Existing Systems: Packaging machines should be integrated with other machines in your production line and processes. Such integration enhances workflow, minimizes downtime, and ensures a well-coordinated production system across all fronts.

- Technological Advancements: Select machines are equipped with innovative features, including an intuitive touchscreen interface, remote monitoring, and data analytics. These technofeatures ease operation, provide valuable insights into production, and enhance management.

By considering these factors, they will be able to select a gummy packaging machine that suits their operational needs, streamlining production, reducing waste, and providing high-quality packaging solutions. Hence, any time invested in evaluation will prove beneficial in acquiring a long-term, low-maintenance, and scalable solution for gummy manufacturers.

Integration of Gummy Packaging with Filling Machines

Presently, alignment of gummy packaging with filling machinery is critical for manufacturers to streamline production workflows and increase overall production efficiency truly. An integrated, automated filling and packaging system ensures that the product is dosed accurately and that its quality remains consistent. Modern systems integrate filling and packaging in real-time, thereby eliminating underfill and overfill errors that can significantly impact production or lead to customer claims.

Moreover, such state-of-the-art integration supports high-speed production lines, allowing manufacturers to fulfill the increasing market demands with luck, while accommodating accuracy. Intelligent sensors, adaptive control software, and modular designs are some of the innovative features present in modern PACKAGING systems. These systems provide a solution for packaging adjustments to accommodate different gummy shapes, sizes, and weights while maintaining a certain degree of tolerance in measurement.

For example, filling systems with adjustable parameters compensate for different product viscosities to ensure accurate and clean transfer of the gummy mix into trays or pouches. This also speeds up the finishing process for market release once combined with an automatic sealing and labeling system.

By leveraging these new facilities, gummy manufacturers can optimize production efficiency, maintain product integrity, and meet stringent compliance standards, all of which will enable them to respond to changes in industry demands and consumer expectations effectively.

Gummy Candy Packaging Types

In the land of Gummy Candy packaging, there are several options that manufacturers can implement, depending on the function, aesthetic, and sustainability desired by their customers. Here are the popular types:

Pillow Pouches:

Gummy-type candies are usually packaged in pillow pouches. They are typically lightweight, inexpensive, and come with either easy-tear notches or pressure-sensitive reclosable zippers to ensure consumers keep the products fresh. Smaller pouches provide considerable positioning opportunities as single-serve portions or controlled sizes for consumers who want to grab and go.

Stand-Up Pouches:

These pouches have great shelf appeal. A gusseted bottom furnishes the pouches with sufficient stability to stand on shelves independently. Many have resealable openings, allowing the product to stay fresh for a more extended period. This format is now also looking into more environmentally conscious ideas.

Rigid Containers and Jars:

Large-sized gummy candy containers, made of clear plastic or glass, are considered premium packaging. They prevent the product from being crushed and maintain its attraction while increasing the product’s presence on the shelves by placing the gummy candy directly in transparent containers. These jars also present opportunities for labeling or branding on lids or adhesive labels.

Blister Packs:

Blister packaging is a specialized pack containing cavities that hold individual gummy candies. Dosage is ensured in the case of functional gummies, such as vitamins or supplements, and protection is offered against external contaminants. They also remain tamper-evident, thus guaranteeing the customer that the product is safe.

Flexible Sachets:

When selling single-serve gummy candies or sample packs, people find flexible sachets the perfect option. The package is a slim and compact device that is inexpensive and highly versatile, suitable for promotional use or quick sales. They can also be highly instrumental in promoting new flavors of gummies into the market, albeit in tiny quantities.

Multi-Compartment Packaging:

Multi-compartment formats are designed innovatively by separating different types of gummies or colors within the same packaging. This attracts consumers with choice while keeping the product intact, away from color or flavor mixing. This format works best for mixed-flavor assortments or limited-edition releases.

The packaging has its advantages for targeting specific marketing segments and catering to customer preferences. Manufacturers can make their products more attractive and increase sales and retention by aligning their packaging with product objectives and consumer preferences. Furthermore, through the use of sustainable materials and easy-grip features, packaging manufacturers can align their packaging concepts with current priorities, such as sustainability and usability, which will provide a strong foundation for market success in the long run.

Benefits of Using Automatic Gummy Filling Machines

Greater Efficiency in the Food Industry

With the advent of automatic gummy filling machines, operational efficiency improved in the food industry. The machines eliminate a significant portion of human labor, including tasks such as accurate weighing, filling operations, and speed controls throughout the production process. Whereas previously human error was one of the limiting factors, now manufacturers can focus on production, minimizing downtime, and thereby saving on costs and ultimately, making larger profits from sales.

Cost-Effectiveness of the Automatic Systems

By implementing an automated system, any industry can evolve. Through evolution comes cost reduction and productivity increase. This automation will reduce dependence on manual labor, allowing companies to lower their operational costs in terms of payroll, employee training, and other expenses. Less waste means more efficient use of resources through precision engineering, and rework is reduced through precision engineering.

Improving Product Consistency and Quality

Automation indeed assures product consistency and quality like almost nothing else. Automated systems, by design, maintain precision for each product, meeting exact specifications and thus limiting deviations that might come through human error. The consistency, multiplied through customer satisfaction, also helps the brand name gain further reliability and excellence.

Studies have shown that thousands of gummy units per hour can be pumped through the automatic filling machine, thereby maintaining uniformity in size and weight, which is a critical quality regulatory standard. Furthermore, with the use of multi-cavity molds and variable parameters, flexibility can be introduced into production in response to market changes, while maintaining high efficiency. This technology, therefore, is termed a blessing in disguise since it can multiply operational capacity and further streamline and standardize product quality, a sine qua non of the industry and an expectation of consumers.

Cost economies are realized through real-time monitoring and predictive maintenance when failure management is done in advance, and downtime is minimized. For example, the production costs for industrial procedures involving automation have always been about 20-30% lower due to the efficiencies and simplification in workflows. Hence, the system is scalable, allowing a company to meet greater demand without incurring substantial capital costs for additional labor and infrastructure, thereby securing long-term profitability.

Each foundation for decision-making has to have data to uphold its standards of quality. Utilization of measurement instruments and sensors with advanced chromatographic technology can enable the monitoring of parameters of processes in real time during manufacturing so that any issues arising from process anomalies that might affect the finishing quality of articles can be detected. Furthermore, predictive analytics would have identified such quality risks for adjustment mitigation, ensuring they remain within allowable industry standards.

Pharmaceuticals and electronics, which are now objectively higher in quality thanks to automation, have seen defect rates drop by as much as 40% in a highly controlled manufacturing environment. A lean approach to quality benefits the end-user and reduces the costs associated with recalls, defects, and waste. Through the automation of quality processes, companies set themselves apart in terms of consistency and performance, thereby gaining the customer’s trust.

Best Practices for Operating Gummy Filling Machines

Regular maintenance and cleaning procedures

Treatment and preventive maintenance for gummy filler machines necessitate consistent application of learning toward thorough perfection. In my routine, I inspect the machine daily for any signs of wear, loosening of parts, or accumulation of residues. Immediate attention to these concerns averts more significant and costly problems. I perform all recommended maintenance, such as changing seals, nozzles, and belts, according to the manufacturer’s suggested intervals to minimize downtime and ensure smooth machine operation.

Taking care to carry out delicate cleaning procedures during the disassembly of the machine, I then inspect all possible hiding places where gummy residues or ingredients could settle, methodically, from filling nozzles and down to the hopper. This is followed by scrubbing and cleaning all parts, using proper food-grade cleansers and warm water, so that no trace of residue remains. Subsequently, the next step is to apply disinfectants to remove any possible contamination. Following this, the parts are quickly rinsed off and thoroughly dried to eliminate any traces of disinfectants that could cause moisture to promote mold and bacteria growth. I check if there is adequate lubrication in moving parts, to facilitate smooth operation after cleaning.

Due to these regular maintenance routines and cleaning procedures, I minimize downtime, ensuring the machine operates consistently and produces high-quality products. Thus, this is my way for guarding both the significant investment in the equipment and the faith the customers put into the final product.

Training the Staff in Machinery for Gummy

Training is vital in gummy production to ensure smooth operations and consistent results in the laboratory. I prefer to have the theoretical aspects come first, followed by the practical elements, in a well-structured training program. Initially, staff are given a general orientation on how machinery operates, the key components, how safety is ensured, and the standard troubleshooting techniques. That is to say, establishing a base of knowledge in which they understand the working of machinery and safety.

After the basics are covered, I proceed to the hands-on training process. I take the trainees one step at a time with the operation of the gummy machines, showing them how to start, run, and safely stop the equipment. I lead them through one or two procedures that they may perform for cleaning, maintenance, and inspection of parts, which helps better detect problems in their early stages. Later, the trainees are encouraged to try the procedures on their own under my supervision, giving them sufficient practice and confidence to operate independently with minimal supervision.

An open-door policy is maintained for continuous training and queries on any concerns. Periodically, staff members get updates on new procedural techniques, safety instructions, and any modifications made to the machines. Such education, experiential at that, builds greater knowledge and strengthens the culture of accountability and teamwork. By investing significant time in training, I have built a team capable of maintaining high operational standards with minimal errors, thereby achieving quality by definition.

Adapting to New Gummy Product Formulations

The process requires a very flexible mind, some know-how, and teamwork to adapt to a new formulation of gummies. If it were me, I would first read through the specifications, really try to analyze the special ingredients involved, especially their characteristics, and then proceed with a close interaction with the R&D team to fully understand whatever it was they wanted to have in terms of texture, taste, and shelf-life while ensuring that the formulation would observe regulations and quality standards. With such early-stage comprehension, it would help establish where some issues could arise, whether with ingredient compatibility, production limitations, or consumer expectations.

Once the formulation specifications are explained in detail, my attention pivots toward testing and refining production methods. I examine the mixing times, temperature controls, order of ingredient addition, and other similar parameters to ensure the end product remains consistent. I also provide production staff with opportunities in trial runs, offering hands-on training to help them become comfortable with any process changes. Production scenarios are simulated, and the results are analyzed to identify any bottlenecks or areas for improvement, thus ensuring the new formula integrates seamlessly into full-scale production with the least amount of hurdles.

Throughout the entire process, communication plays a crucial role. I meet with cross-functional teams to observe progress, note issues, and glean insights. Resolution of matters in a communal fashion induces quicker problem resolution and gives ownership to the teams toward the quality of gummy. My approach is proactive and adaptive, ensuring that new formulations are installed to maintain product quality and operational efficiency.

Frequently Asked Questions (FAQs)

What type of gummy filling machine is available at present for candy production?

Gummy preparation has many filling machines depending on the gummy shape and size. Some are better for softies, while others are meant to fill gummy bears or other types of candy. These terms may be applied to machines such as rotary filling machines, sachet filling machines, or automatic counting machines. Based on production requirements, you want to ensure a consistent quality and output rate, where the filler can process 900-1000 gummies per minute. The better automated the packaging is, the higher its efficiency and reliability become.

So, how does a filling machine manage to fill accurately in this candy and gummy production process?

Festooned with precision-filled technology, the candy filling machines, by their accuracy, perform their function of filling gummy products. These would be advanced gummy counters and weighing mechanisms to ensure that the amount of gummy candy in rigid containers, be they bottles or pouches, is exact. These machines, equipped with traveling funnels and continuous motion features, effectuate minimum downtime while maximizing productivity. Furthermore, their high-speed operation is well-suited to the demands of the food industry, while simultaneously ensuring product integrity.

What advantages does packaging equipment have for gummy candies?

Special packaging equipment for gummies offers several advantages, including increased efficiency and reduced labor costs. The automatic packaging machines count, fill, and pack gummy products for the packaging line. These machines further package a diverse range of gummy types, allowing for more flexible packaging options to cater to different market demands. With features like precise filling and sophisticated counting of gummies, it also enables manufacturers to ensure that each package meets the exact grade of assurance for maximum output. This will result in increased customer satisfaction and higher sales.

Can gummy filling machines be used for other food products?

Yes, gummy filling machines can be modified for other foods, especially those sharing a similar texture with gummy candy. For soft cinnamon roll-like candy or nutraceutical products that need accurate filling, the same packaging machinery would be beneficial. These machines offer versatility in accommodating a wide range of gummy product shapes and sizes, making them ideal for all types of gummy products. With some modifications, they would be suitable for various packaging operations beyond candy, providing a wise investment for cost-conscious manufacturers looking to develop additional product lines.

What is the role of a hopper in a gummy filling machine?

In a gummy filling machine, there is a hopper that stores gummies temporarily before dispensing them. Since a hopper ensures a steady flow of gummies to the filling zone, allowing the machine to operate without downtime, a well-designed hopper would facilitate easy loading and unloading of gummy products, thereby enhancing production efficiency. Therefore, blockage of filling is avoided, and absolute counting leads to an increase in productivity and reliability of the machine.

How Can I Choose the Right Packing Machine for My Gummy Products?

Machine selection for packaging your gummy products plays an important role to consider, as it depends on the packaging needs, production volume, and heating requirements of your gummy products. Essentially, machines suitable for either pouch filling or container filling should be considered, taking into account the variations in packaging types. Features such as automatic counting and mechanisms that ensure precise filling processes to maintain uniform quality standards should be sought after. While testing for compatibility with your production line, note if the maintenance requirements could disrupt your smooth operations.

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.