In planning for production efficiency in 2025, a biscuit-making machine...

Read MoreHow to Choose the Best Biscuit Making Machine for Factory Production Efficiency in 2025

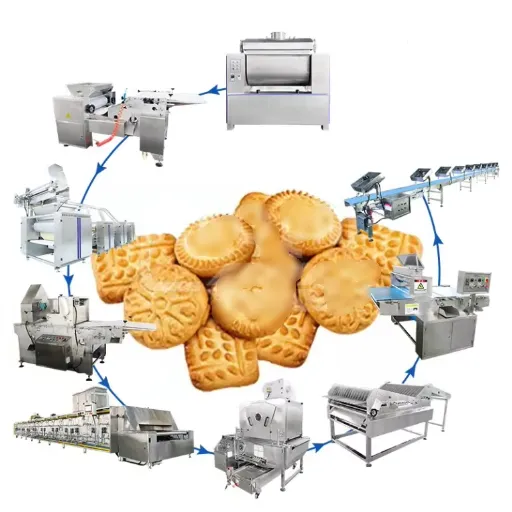

In planning for production efficiency in 2025, a biscuit-making machine would be one of the most important factors left for decision by the industries. Generation next biscuit-making machinery is expected to put production processes to a new level of automation and energy efficiency with its scalability. Now, if there is a variety of machinery with different features and capabilities available for purchase, how does sellers or buyers choose the best that fits their factory? This guide will take on everything from site-specific technical parameters through production capacity assessment, cost-effectiveness, and long-term ROI, allowing one to make a choice that supports the very success of their operational activities.

Understanding Biscuit Manufacturing Machines

What is a Biscuit Making Machine?

A biscuit-making machine is an entire industrial system designed to increase output by making biscuits more quickly on a large scale. These machines perform various tasks, including dough mixing, forming, baking, cooling, and packaging. The advanced biscuit-making machines retain the high engineering precision to maintain exact specifications in size, shape, and texture of biscuits, while simultaneously ensuring very high productivity and less packing waste.

Modern machinery uses innovations such as PLCs, automation sensors, and energy-efficient designs to satisfy the ever-growing demand for high-speed production and customization. A few of these machines produce a few thousand units per hour, accommodating a wide variety of biscuit types — from plain cookies to cream-filled or coated ones. Moreover, they are designed following food safety and hygienic standards: all stainless steel with resistant coatings to prevent corrosion, for ease of cleaning.

Types of Biscuit Manufacturing Machines

Rotary Machines

Inherently controlling a shaping method for soft doughy biscuits with minute patterns, these rotary machines operate by the rotation of a drum whereby the dough is pressed into shape through cavities that bear neat and uniform designs. Modern and high-speed, the rotary molding machine produces thousands of pieces an hour, accurately and with utmost consistency. Some of these machines include sophisticated control systems that control dough thickness to reduce wastage during production.

Wire-Cut Machines

Wire cut machines are very versatile, and very much required for shortbread and butter-type cookies among others. The method of operation is that the dough is extruded through the die and cut by the thin wire in order to keep the shape and size uniform. Modern wire-cut machines employ PLCs to permit quick changes in recipes and customization. This flexibility suits those producers who need an equally flexible portfolio of products.

Depositor Machines

A depositor machine is well-suited for making filled biscuits or layered biscuits. It deposits dough or filling with precision in different patterns and layers, enabling manufacturers to work on innovative designs. Most depositors come with multi-lane systems to maximize production levels. The more advanced ones come fitted with servo-actuated technology for enhanced control and consistency.

Tunnel Ovens

Used as well in biscuit production, these ovens would not act as manufacturing machines in the strict sense of the term. The tunnel ovens guarantee even baking in vast volumes of biscuits on either direct gas-fired or electrical heating equipment. Modern tunnel ovens are designed to be energy-efficient, featuring a zoned temperature control that allows for diverse baking profiles to suit different types of biscuits.

Enrobing Machines

Presumably applying coating substances like chocolate, yogurt, or glaze, enrobers are the second system in the manufacture of coated biscuits. Accuracy and speed were the foundation of such machinery, which coats every biscuit evenly, so as not to damage the biscuit structure. Modern enrobers are equipped with cooling systems to quickly harden the coating, making it both durable and attractive.

Each of these machines holds the utmost importance in the manufacturing process. These machines are integrated with the latest technology in automation, real-time monitoring, and energy-efficient applications to meet the ever-growing needs of the global biscuit industry. These machines provide an advantage for manufacturers to achieve greater productivity, product variety, and compliance with highly demanding quality standards.

Key Features of Automatic Biscuit Making Machines

Automatic biscuit-making machines are built with the sole purpose of easing the production process, heavily focusing on precision and quality. Some key features include:

- ⚙️ Advanced AutomationThese machines come with the latest automation techniques, providing a continuous operation from dough mixing to packaging. Programmable Logic Controllers (PLCs) ensure production remains consistent with limited human intervention and lower errors.

- 📊 Production Capacity and CustomizationModern biscuit machines account for high production volumes, with capacities ranging from 500 to about 2,000 kgs per hour, depending on the setup. Furthermore, they provide support for furnishing the biscuit molds and cutters, thus permitting manufacturers to vary biscuit shapes, sizes, and textures.

- ⚡ Energy EfficiencyWith delicate in-built technicalities such as insulated ovens and variable speed drives, power consumption in these units is kept low. The icing on the cake is the decreased operating cost and the increased participant contribution towards sustainability.

- 🎯 Precision and Quality ControlTemperature, humidity, and dough thickness might all be measured and controlled in real time, thanks to sensors combined with a camera-monitoring system. Product quality and product consistency, therefore, are increased from batch to batch.

- 🧼 Sanitary DesignThe machines are constructed out of food-grade stainless steel and designed to be easy to clean, thereby meeting international hygiene standards. Smooth surfaces, fewer joints, and removable parts serve as safeguards against contamination and ease of maintenance.

- 🔥 Baking Systems with VersatilityThe machines incorporate hybrid tunnel ovens with direct and indirect heating options, allowing various baking profiles for several biscuit varieties, from soft cookies to crisp crackers.

- 🛡️ Safety FeaturesOperator safety and the prevention of accidents during production are ensured by safety devices, including emergency stop buttons, thermal cut-offs, and the complete enclosure of moving parts.

Automatic biscuit-making machines use these complex features to enhance manufacturer efficiency, expand product variety, and ensure compliance with stringent industry standards, thus projecting them toward success in a competitive market.

Factors to Consider When Selecting a Biscuit-Making Machine

Production Capacity and Efficiency

When choosing a biscuit-making machine, production capacity and efficiency are critical parameters that influence operational output and scalability. Machines nowadays are meant to cater to almost every production volume range, from small-scale units producing just a few hundred biscuits per hour to industrial systems churning out thousands in the same span of time. These high-efficiency machines employ advanced automation technologies, such as programmable logic controllers (PLCs) and servo motors, to maximize speed, accuracy, and precision while minimizing downtime. Energy-efficient designs optimize heating elements, feature power-saving modes, and minimize their operational costs without compromising on performance. By understanding the production needs against the specifications of available machines, businesses can ensure that today’s requirements are met, while also providing provisions for growth opportunities in the near future, thus making production a more sustainable and responsive process.

Customization Options for Different Biscuit Types

Consider the biscuit factory as one of those massive kitchens catering to your particular needs, from the biscuit type selected down to texture and flavor. Being treated roughly or simply being put through wrong machinery components, ingredients, and baking setting combinations will cause a biscuit to miss its target specification. For instance, rotary molding fits soft dough type biscuits with elaborate shapes and uniformly repeated patterns, whereas wire-cutting is apt for dough with inclusions like chocolate chips or nuts.

In addition, different biscuit formulations may also require the baking profile to be tweaked. For example, cream biscuits must be baked within a fixed temperature range so that they are suitably filled and there are no complaints of unevenness. Making gluten-free high protein biscuits is an exercise in ingredient selection and processing to improve their structural properties and baking performance.

Further customized automation considers programmable logic controllers (PLCs) and recipe management software to allow automatic changeover from one type of biscuit to the other. This excludes human interference in the ingredient ratios, the dough consistency, and so on, to pan temperature, so waste can be minimized, and efficiency can be increased. Thus, manufacturers utilizing these technologies can meet the ever-shifting customer requirements for quality and quantity.

Automation Level: Fully Automatic vs. Semi-Automatic

The level of autonomy and the degree of human intervention distinguish between completely automatic and semi-automatic systems. To continually monitor and adjust during production processes with diminishing human intervention, fully automatic systems incorporate higher-grade sensors, robotic technologies, and software algorithms. These systems are primarily used in high-demand environments that consider consistency, speed, and accuracy as paramount requirements for operational processes. As an instance, fully automated biscuit manufacturing lines conduct processes from mixing, shaping, baking, and packaging in proper synchronization with minimal stoppage for maximum throughput.

Nodesman systems incorporate automated processes alongside manual processes, thus providing some degree of flexibility while requiring manual intervention in a few operational stages. They are often sought in places where production volumes are limited or high product customization is frequent, as operators may manually intervene or override automation without stopping the entire flow. Semi-automated systems definitely incur more labor intensity than fully automated systems. Hence, for small- to medium-scale industries, these configurations go hand-in-hand, practically and economically, with various product specifications.

Finally, a decision regarding which system is fully automatic or semi-automatic depends on the top priorities involved, specifically the production scale and product variety of the manufacturer.

Integration with Factory Production Lines

Designing an Efficient Biscuit Production Line

Keeping in view the above objectives, designing an efficient biscuit production line must involve systematic planning to enable productivity, ensure uniform quality, and promote resource utilization.

🔹 Ingredient Handling and Mixing Systems

Good ingredient handling starts with accurate measurement and quality control of raw materials: flour, sugar, and fats. Automated dosing and mixing systems guarantee accuracy and homogeneity, with new-generation ones even capable of adjusting the formulation parameters according to the biscuit variety. The more sophisticated systems incorporate PLCs to carry out batch mixing precisely, thereby reducing wastage and increasing efficiency.

🔹 Forming and Shaping Machines

The forming process is indeed considered the final stage in shaping the biscuit in terms of its shape, size, and weight. Rotational molding, wire-cutting, or laminating systems can be used, depending on the type of product desired. Manufacturers usually choose more versatile shaping machines so that they can, with minimal downtime, adapt to market demand for different biscuit designs.

🔹 Baking and Heat Transfer Technologies

The baking stage consumes the most energy and significantly impacts the quality of the end product. Tunnel ovens with zonal temperature control and uniform heat distribution enhance thermal efficiency and are used for baking products evenly. A multi-stage baking process is usually employed in modern ovens to attain the correct texture and color while still avoiding overbaking or unevenness. An energy recovery system may also be set up to reward cost savings at this stage.

🔹 Cooling and Conveyor Integration

If proper cooling is not applied, product integrity must be stabilized before packaging. Cooling conveyors are likely set for 50% of the baking length to ensure a steady temperature reduction, thereby preventing cracking or warping. Smooth conveyor integration between baking, cooling, and packaging will enable smooth transitions between processes and improve handling to avoid damage.

🔹 Packaging Automation

Flow wrappers, vacuum packs, or automated tray packers would increase throughput while maintaining seal integrity for extended shelf life. More advanced systems equipped with cameras for quality inspection can assess defective products in real time and reject them, leaving only each conforming product eligible for sale.

🔹 Control Quality and Monitoring

Inline quality monitoring systems, implemented using sensors, cameras, and AI-based algorithms, allow for the real-time detection of defects and the verification of compliance regarding weight and moisture levels. The data furnished by these systems expedite the production process, allowing the manufacturer to make prompt adjustments to maintain quality.

🔹 Energy and Waste Management Systems

Sustainable concerns are at the forefront of biscuit manufacturing. Systems for managing energy consumption, reducing wastage, and occasionally recycling excess dough from the forming process help cut costs and ensure environmental compliance.

Ultimately, the design of efficient biscuit production lines is an exercise in balancing automation with precision and adaptability. With investments in state-of-the-art technology and the continuous monitoring and analysis of operational data, manufacturers can accelerate productivity and reduce costs while adapting smoothly to changes in demand.

Choosing the Right Packing Machines

Selection of packing machines is another decisive step for ensuring smooth operations and making a production line for biscuits stand reliable. Packers of the modern types will be made to suit the particular needs of the various class of biscuits ranging from very fragile shortbreads to the more heavy cracker type. Speed, accuracy, sanitation, and cooperation with the upstream production line are factors to give due consideration.

Flow wrappers at high speeds are better for manufacturers who intend to pack hundreds of units per minute while keeping precision intact. They are equipped with the so-called producers behind the work, from feeding to sealing in an airtight manner, to maintaining the freshness and optimizing CE. Thus, tray-packing systems are better for delicate biscuit products that need more protection, as they gently place products in rigid containers to minimize breakage.

Energy efficiency is another important criterion. Ones consuming less power will not only have their price of operation go down but will also meet the sustainability criteria. Proper use of machine learning in combination with IoT integration will allow for real-time monitoring and predictive maintenance, thus cutting downtime and boosting productivity.

High dynamic packing should be considered in an investment that can adjust to changes in product shape or size, ensuring long-term flexibility. By addressing production demands and incorporating newer packing technologies, manufacturers will be able to achieve seamless production while continually satisfying customers who expect high levels of quality and consistency.

Maintaining Workflow with Dough and Cookie Production

The dough and cookie industry witnesses productivity and efficiency under control of processes, an unaltered supply of ingredients, and incorporation of high technological means. Standardization of weight and size of products through an automated system reduces human interference and increases throughput. The dough is quality-wise affected by temperature and RH all through mixing and resting. Hence, and these parameters are critical ingredients for the baking quality of the end product.

Equipping machines must be regularly calibrated; strict sanitation must be enforced to reduce contamination as well as downtime caused due to maintenance issues. Sensor and software integration facilitate data-driven decision-making that produces actionable evidence related to production metrics such as batch yields, waste percentages, and line specification so that operations may be scaled in a sustainable way by standardizing workflows with the aid of technology, while guaranteeing product performance in a consistent manner and in the very same array of safety standards.

Latest Trends in Biscuit Making Technology

Innovations in Fully Automatic Biscuit Making Machines

The increased efficiency and accuracy in food production, an incredible gain for the modern age by giving fully automatic biscuit machines, could have been possible only yet. The machines use advanced robotics and precision sensors for automated operation to achieve an ever-highest level of productivity and quality of the output from these machines. The other huge advancement is that AI-based control systems are created to monitor in real time and adjust various parameters, such as baking temperature, conveyor speed, and dough thickness, under control, so as to lessen to the maximum extent of their occurrence by human intervention and error.

Machines today, with modular designs, can be adjusted by manufacturers to suit product types and sizes on the production line. For instance, extremely precise dough deposition with servo mechanisms and uniform layering using an advanced laminator are central to the successful realization of baked good quality. Energy-efficient heating systems have come with infrared and convection baking systems that reduce energy consumption while maintaining the level of baking performance.

Translation: Such recent technologies not only enhance production methods with sustainability in mind but also go a step further. The new technologies churn out waste recovery automatically, leading to the least possible wastage of raw materials. Maintenance of machinery using IoT sensors to predict faults lessens downtime since maintenance can be effectual prior to a fault. Hence, the developments raise the fully automatic biscuit-making machinery, keeping in view the current needs for processes that are high-speed, reliable, and green in nature.

Smart Machinery for Enhanced Production Efficiency

Biscuit production intelligent machines employ cutting-edge technological applications such as AI, machine learning, and Industrial Internet of Things (IIoT) to optimize manufacturing workflows and boost production efficiency. With AI and ML algorithms, these machines analyze production data (of huge sizes) in real-time and make correct adjustments in temperature control, mixing ratios, and baking times, thus minimizing variance and ensuring consistent output with the desired quality in large production volumes.

In addition, IIoT-enabled machines can help different portions of the line to coordinate with one another properly because of interconnected sensors and the cloud systems. They also keep a watch on KPIs (key performance indicators) on energy consumption, use of matter, or product output levels in real time. A realized example is to employ predictive analytic techniques for limiting unexpected breakdowns by determining a pattern in machine behavior, which results in an increase in equipment uptime.

By virtue of conserving energy and reducing waste, this ingenuous system also fosters sustainable development for the industry. When manufacturers choose to save energy-prone processes, they save huge amounts of energy and cost and in doing so minimize greatly their carbon footprints. These developments therefore show how state-of-the-art machinery in biscuit production leads to improvements in speed, reliability, and sustainability.

Sustainable Biscuit Manufacturing Solutions

Being environmentally considerate in manufacturing this kind of biscuit would require the use of the latest technologies to reduce the adverse effects on the environment while still maintaining productivity and quality. Thus the heat generated during baking is utilized elsewhere through the efficient ovens equipped with heat recovery systems, saving a lot of energy. Water management systems, on the other hand, conserve this gold by recycling water used for cleaning and cooling purposes.

Materials also speak adamantly for sustainable productionism. To some extent, the production of biodegradable packaging within recyclable packaging solutions ensures that their distribution follows the expectations of the eco-conscious consumers. By using new materials that keep the product fresh while being environmentally friendly, manufacturers could significantly reduce plastic waste.

Operationally, predictive analytics and monitoring software inform facilities of inefficiencies induced on site, allowing for a more optimal resource application. Proactively generating less waste, streamlining operations, and shrinking greenhouse gas emissions due to stringent environmental and corporate Sustainability goals spark Responsible manufacturing into a backbone for conscious environmental efforts in food production.

Conclusion: Making the Right Choice for Your Biscuit Factory

Getting Cost vs. Benefit Evaluated

When examining the cost vs. benefit in eco-conscious manufacturing for my biscuit factory, I focus on the long-term sustainability and financial viability of the investment. In complete terms, the switch to green processes and technologies first and foremost entails some capital investment for new machinery, energy system upgrades, and acquainting employees with the changes. But from a longer-term perspective, such costs are made worthwhile through savings from reduced energy consumption, water usage, and landfill fees. Most governments, in fact, tend to support sustainable manufacturing activities through financial incentives in various forms, such as tax credits and grants, thus reducing the initial cost burdens.

The advantages really extend well beyond mere money. The promotion of sustainability earns legal protection for the organization from increasingly stringent environmental laws that could otherwise exact a fine on her company at the expense of its reputation. An ordinary market value will, after all, be attached to the clean green brand. Consumers bear acute consciousness vis-à-vis sustainability issues and prefer to patronize companies that somehow vaguely represent their values. If consumers had acquired a preference toward environmental causes, given greener loyalty and bought entry into premium locales would very well translate into revenues.

On the whole, grants are involved in upfront management fees, but good help makes it a worthy investment through financial gains and an upward trajectory in reputational value. From a thorough analysis of energy-saving avenues, operating efficiency gains, and industry positioning opportunities, I firmly conclude that eco-conscious manufacturing should become a priority for my factory, aligning my business objectives with my deeply ingrained environmental commitments.

Future-Proofing Your Biscuit Manufacturing Business

A truly multidisciplinary approach must be given to securing the biscuit manufacturing business for the future, covering all aspects: technology, sustainability, and market trends. Perhaps one big step is the adoption of automation and artificial intelligence (AI) in production processes. AI for quality control, for example, would use an exemplary approach to enforcement of product standards, while automation enhances speed and reduces inefficiencies. Finally, data analytics, which track consumer preferences and market trends, must be harnessed to inform decisions that keep my business competitive on an increasingly fast-paced market environment.

Sustainability is just one eye for market demand and the other for CSR. Focusing on energy efficiency in machinery, procuring from suppliers who use sustainable methods, and cutting down packing waste maximizes cutting down on any negative externalities on nature, thereby also adding to consumer demand for brands that take an environmentally friendly approach. Funds directed into clean energy alternatives so that factory operations run on the winds of solar or wind power will instead offer long-term cost stability for establishing my business in the forefront of sustainable production.

Lastly, the changing customer dynamics in the market for healthier food options with organic labeling and allergen-free factors have to be taken into consideration. Offering biscuit varieties with gluten-free, low-sugar, and plant-based flavors would allow me to attract a large number of consumers. Standing in constant review of my business supply chain, marketing plan, and pipeline of product innovation is of utmost importance for my business to stay afloat while the market situation is fluid and emerge at the forefront of future trends. Such far-reaching, proactive preparedness lays the foundation for ensuring the longevity of my biscuit manufacturing withstanding the remaining competition and growing concern for sustainable living.

Search for Experienced Advice and Recommendations

The pertinent factor for biscuit manufacturing businesses to build resilience and bank on future potentialities by tapping into expertise and employing data-driven methodologies. Diversifying a range of products into better-for-you items such as gluten-free, low-sugar, and plant-based biscuits, following ongoing industry trends, purportedly satisfies the burgeoning customer demand and, at the same time, presents problems of health and sustainability. According to several studies, worldwide opportunities will spontaneously grow for plant-based products. Aligning with consumers’ increased awareness of dietary and environmental issues, I wish to stay prepared for the future by actively innovating my products so that my company caters to customer wants and remains their choice.”

Also, sustaining a supply chain and sustainable standards should be the way through which they overcome the issues brought about by changes in the economic and logistical landscape. Green suppliers will then be partnered with, along with implementing green processes that reduce the carbon footprint, thereby having the brand considered on a social level. Customer preferences and coming trends shall be analyzed and predicted through analytical tools, thus giving me an edge in correct marketing and less risk in overproduction or wastage.

The approach only needs to be further cemented by any specialized consultation available from industry experts, consultants, and market analysts. From time to time, I can also rely on an assessment of my supply chain and marketing frameworks and, more generally, of operations so as to apply recent technologies and insights, letting my business remain flexible to change in an ever-changing environment. Working with such professionals acts to refine these strategies further and better allows me to concentrate on growth targets-proving my interest in competing in a market ever more focused on health and sustainability.

Reference Sources

-

- Alibaba – 2025 Industrial Biscuits Making Machinery: Features automatic production lines with long service life and high-quality output.

- Skywin Bake – 2025 Hard & Soft Biscuit Production Line: Offers high-capacity machines for both hard and soft biscuit production.

- Alibaba – 2025 Wholesale Biscuit Making Machine Fully Automatic: Highlights fully automatic machines with various capacities tailored for factory needs.

- New Era Machines – An Emerging Global Leader In Biscuit Manufacturing: A global leader in biscuit machinery, showcasing innovations for 2025.

- SaintyCo – Biscuit Making Machine: The Complete FAQ Guide: A comprehensive guide to choosing the right biscuit making machine based on production demands.

Frequently Asked Questions (FAQs)

❓ What is a biscuit-making machine for factory use?

A biscuit-making machine is an industrially-assisted piece of machinery intended for automating the manufacture of any type of biscuit, including hard, soft, and sandwich biscuits. These machines can mix, mould, and bake the dough on the contrary that makes the entire business of biscuit manufacturing quite straightforward. Normally, they are usually constructed from stainless steel to confer durability and hygiene in food processing. They can also be customized to suit your very own needs, making it greatly useful for commercial baking. Together with cutting-edge technology, these machines greatly increase earning potential by making production easier.

❓ How does an automatic biscuit production line work?

The automatic biscuit production line consists of innumerable machines working in unison to shape the biscuits. The process begins with a mixer mixing several ingredients to form a dough. Later, the dough is moved by a conveyor to the molding section, wherein various cookie-cutter molds produce different shapes of biscuits. The biscuits are then carried on the conveyors to an oven suspended high in the air wherein billet baking is done; afterwards, the biscuits are cooled and packed by the packaging machine. Hence, we can say, “From start till finish, the biscuit method is fully automated,” where the maintenance of the biscuit can be very important for cutting labor costs on the production team, thereby improving the output efficiency.

❓ Can one customize biscuit machines for their production requirements?

These are biscuit-making machines available with many manufacturers: options are offered for customization based on various production needs. Customizations are also allowed for parameters such as biscuit size and shape, along with different cookie designs and types of sandwich cookies, among others. It can also be customized by capacity, allowing you to find machines that will produce either a relatively small batch of biscuits or go into commercial biscuit baking. On top of that, you can get an automatic cookie mold and packing solution tailored to your needs so that the production line will flow smoothly. The factories producing these machines will help you to choose the best solutions for either small or large operations.

❓ What can the cookie machine make?

Cookie machines are found in the trade and can produce many sorts of cookies, including those that are crispy and those that are soft, besides specialty items like shortbread and wafers. In layman’s terms, the machine can make different kinds of biscuit and cookie styles according to preference. Using cookie molds, they can make an array of cookie shapes and sizes. More alluring on the consumer is better. They also mix with either a harder dough for the crunchier cookie or a softer one for the more delicate variety. Such flexibility pretty much makes cookie machines an important feature in the highly competitive baking realm.

❓ What role does packaging play in biscuit manufacturing?

Packaging takes an important role in biscuit manufacture, as it protects the product and gives it a longer shelf life. After baking and cooling, the biscuits are fed into the packaging machine which wraps the product so that it is secure for distribution. Some preferred packaging solutions focus on packaging for keeping the product fresh and safeguarding it from shattering into pieces during transport. Eye-catching packaging attracts the consumers to buy the packaging, which forces the manufacturer to invest in good packaging. Packaging can be custom-made to match the branding of a product offering, in-turn assisting in its marketing.

❓ What benefits does an automatic biscuit-making machine offer to a factory?

Efficiency and labor rates are the two large benefits automatic biscuit making plants have to offer. They will operate twenty-four hours, trying to make as many biscuits as possible while requiring marginal human involvement. This system significantly minimizes human error in the production line, thereby reducing losses. Another advantage is that with automatic biscuit making, the quality of the production remains uniform throughout, and so the entire batch of produced biscuits meets predetermined standards. Depending on its configuration for certain production processes, the value of this machine can be highly enhanced, thus making it worthy of purchase for any bakery or manufacturing establishment.ed to complement the branding of a product, in turn facilitating greater marketing.

Related Posts

- Understanding the Key Features of a Modern Gummy Worm Machine for Efficiency

- Master the Art of Baking with This Guide on How to Use Biscuit Machine Effectively

- The Best Lollipop Making Machine: A Comprehensive Guide to Lollipop Manufacturing

- The Sweet Journey of Marshmallows: From Ancient Roots to Campfire Treats

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.