Gummy pouring machinery is at the heart of chocolate and...

Read MoreKey Factors That Make a Gummy Manufacturing Machine Reliable and Efficient

When it comes to producing fine-quality gummies in large quantities, the reliability and speed of the machine you choose are as important as the process itself. Due to a massive surge in demand for these goodies—nutritional, candy, or medicinal—manufacturers are under pressure to produce at very high standards while also ensuring maximum output. However, not all machines are designed the same way. Understanding the factors that make a gummy manufacturing machine reliable and efficient can significantly improve your process. This article discusses what separates an efficient machine from one that is inefficient, providing a roadmap through the technology, features, and operational concerns that pave the way to success. If you are upgrading existing machinery or just entering the gummy market, the knowledge this guide provides will undoubtedly help you make an informed decision. Ready to cut through unnecessary processes and lay the foundation for consistent quality?

Understanding Gummy Manufacturing Equipment

Components of a Gummy Machine

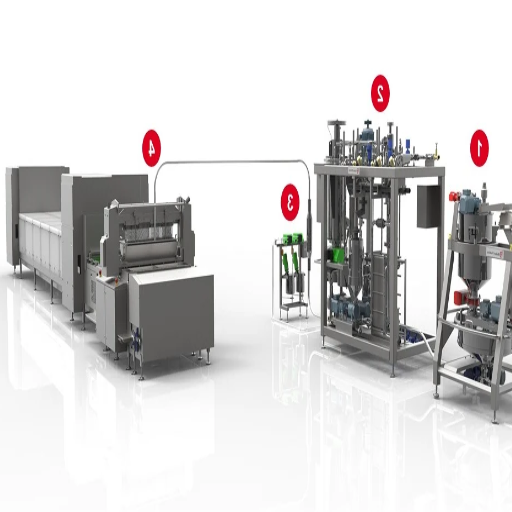

A production line for gummy manufacture consists of a complex machine that handles all stages of gummy production, with the intent of maximizing efficiency, maintaining consistency in product output, and ensuring quality. Below are the major parts of the gummy workstation and their use:

Mixing Tank

Also known as a mixing tank, it is used to combine ingredients such as gelatin, sweeteners, flavors, and colors. The most advanced types are fitted with controllers that can maintain temperature precisely and automatically stir the mixture for a fixed time, ensuring homogeneity, which is crucial in guaranteeing a consistent gummy quality.

Cooking System

The cooking system is designed to heat mixtures to the desired temperature, primarily through the use of steam or electrical heaters. The gelatin becomes fully dissolved during heating, having undergone the combined effect of immersion for the correct times in the water in which the gelatin is dissolved, to retain the smooth, elastic character of the gelatin. The automation of monitoring reduces manual errors and enhances the system’s energy efficiency.

Depositor Unit

It is the depositor’s responsibility to fill gummy molds accurately, ensuring size and weight uniformity for each piece. High-precision servo-controlled depositors increase accuracy, lessen material waste, and give the flexibility of producing multi-colored or layered gummies.

Molds and Cooling System

Since these molds are customized, they determine the shapes and sizes of gummies to be produced. The majority of machines use molds made out of food-grade silicone or metal, which have qualities of being durable and non-stick. The cooling system then solidifies the gummy mass after depositing, with newer machines being equipped to carry out cooling in some adjustable temperature zones for increased speed and efficiency.

Demolding Mechanism

A demolding station removes the gummies from the molds with care so as not to damage their shape. Since automated demolding processes speed up production and reduce the need for operator-intensive tasks, they enhance the consistency of the output.

Flavoring, Coating, and Finishing Elements

Some gummy machines also feature optional modules for the finishing coat, such as sugar or sour powder. Flavor sprays and oil coating systems help ensure an even spread, allowing for better texture and taste and preventing stickiness.

Control Panel

The control panel serves as the command center for adjusting parameters, including temperature, speed, and operational timing. Many machines today feature touchscreen controls, offering an intuitive user interface and IoT capabilities for real-time monitoring and data analytics to optimize production.

Conveyor System

The conveyor system is designed to transport gummies from one stage to the next, ensuring a smooth flow. In an advanced setup, conveyors may be equipped with sensors for quality inspection to reject defective products automatically.

Types of Manufacturing Equipment for Gummies

These modern gummy manufacturing equipment are diversified to suit exact and wide manufacturing needs. The main categories of equipment that are commonly used in gummy manufacturing are:

Temper and mix equipment: Tempering and mixing equipment constitute the first stage of gummy manufacturing, wherein ingredients such as gelatin, sweetening agents, flavoring agents, and coloring agents may be mixed. These machines also mix ingredients uniformly while applying just the right amount of heat, ensuring that the ingredients are not burned and lumps do not form. Some very large melters can even process (melt) hundreds of kilograms of base material from a single batch, thereby reducing activity time for a large commercial operation.

Depositing Machines: These machines for depositing are essential for the accurate formation of gummies into their respective shapes and sizes. Remote-controlled servo systems are used in advanced models of these machines, allowing the dose to be as small as desired, thereby minimizing any change in the gummy dimensions and weight. Another feature catching interest is multi-layered depositing or filling the cores with a different texture (say, liquid-filled gummies), quite in line with the market trend for product differentiation.

Cooling Tunnels: After being deposited into the molds, the gummies must pass through cooling tunnels to solidify and set. In these modern tunnels, an air circulation system is controlled to ensure even cooling required for maintaining the structural integrity of the gummies. Modular configurations are available and can be scaled up as the production expands, depending on the required capacity.

Demolding and Coating Equipments: After setting, the gummies, in most cases, undergo extraction from molds, for which demolding systems are used. Modern systems employ gentle conveying methods to prevent product damage or deformation. Then, coating equipment applies layers of sugar, sour powder, or oil glazes that impart texture and flavor, as well as anti-stick properties.

Inspection and Quality Control Systems: Equipped with precise sensors, inspection machines detect anomalies in weight, size, and shape, ejecting all nonconforming products. They can also detect impurities with X-ray or vision-based technologies, ensuring increased product quality and compliance with industry standards.

Packaging Equipment: Packaging varies in substance from single sachets to huge bulk bags, all depending on distribution requirements. These automated systems are intended to weigh, seal, and label so that speed and packaging accuracy with the processes remain uniform. The preferred options lately are for using environmentally friendly materials so that the process moves towards sustainability.

With the integration of these modern systems, gummy manufacturers have the opportunity to utilize production efficiency to meet variations in consumer demand through new flavors or environmentally friendly packaging options. Investing in flexible and scalable technology results in eventual savings and helps keep operations running competitively in a fast-moving market.

Importance of quality in gummy machinery

The gummy machinery must be of top quality to adhere to consistent standards of production and meet consumer expectations. Such machinery permits the maintenance of an exact temperature, a permitted mixing speed, and a ratio of ingredients, thereby controlling all the factors that determine how gummy is produced, including the perfect texture, flavor, or appearance. Advanced equipment reduces errors in operation while decreasing downtime. There is, therefore, increased production efficiency and better cost-effectiveness.

Additionally, high-quality gummy machinery promotes food safety compliance by utilizing materials and designs that meet the strictest hygiene standards. For example, a stainless steel component with corrosion resistance and an easily cleaned, beautiful appearance nurtures high-level sanitation, thereby decreasing potential contamination threats.

Automated procedure controls with adequate quality checks would also contribute to food safety, whereby each batch, for example, is monitored in real time for consistency, allowing any deviation from set quality standards to be immediately addressed.

Another wise investment is into machinery that is reliable and scalable. Engineering offers customization and flexibility to manufacturers when reacting to market trends and consumer demands for new types of flavors, shapes, or diet-specific gummies. Where the machinery quality is above all considered by the gummy makers, their reliability in operation stands in a competitive, ever-evolving industry and ensures the quality of products is well-maintained.

Key Features of a Reliable Gummy Making Machine

Gummy Production Speed and Efficiency

The trick nowadays in gummy manufacturing concerns balancing efficiency, fast pace, and quality consistency. If the machine is of modern finesse, it would manufacture thousands of gummies an hour with the very grounds of speeding up processes in terms of shape and texture so much that flavor may co-vary with them. From temperature control to depositor systems and the likes, all kinds of automation and high-tech gadgets have been making production easier to undergo through so many advances.

For example, degassing machines with high-pressure depositing capabilities can generate multiple batches in parallel, thereby increasing throughput without compromising quality. Green design principles, including energy efficiency, helped streamline operations and lower the cost of these tall machines, supporting the production objectives set by companies seeking to satisfy new market demands and meet sustainability standards. Such innovations ensure that the world of gummy production stays competitive in a rapidly evolving confectionery environment.

Dose System in Precision for Gummies

Production-dosing systems that are highly precise have to be in place in the gummy realm to meet stringent quality and characteristic specifications. Advanced dosing systems allow the distribution of uniform doses of active or functional ingredients to each gummy-like vitamins, supplements, or cannabinoids-wthus giving a uniform batch to the consumer. Dose inconsistency would imply non-compliance to regulations, whereas inconsistencies in flavor, texture, and efficacy would go against consumer trust.

With the aid of state-of-the-art dosing systems, manufacturers can effectively prevent waste, conserve ingredient use, reduce production errors, and thereby strive for optimal operational efficiency.

A significant advancement in dosing technologies is the automated control of dosing. These systems monitor ingredient flow through sensors and various data sources. They detect deviations and react by adjusting the dose instantly during production. One example is where volumetric or gravimetric dosing systems account for different types of ingredients to ensure smooth flow during the formulation of any gummy complexity.

The property of automation also helps in upscaling, as manufacturers seamlessly transition from small-batch artisanal gummies to large-scale industrial production with equal quality and precision.

Allergy-producing or therapeutic active agents require special care in their gummi manufacture because the slightest contamination may be considered a great quality concern. Modern dosing systems, on the other hand, pay huge importance to cleanliness and eliminating cross-contamination and hence are modular in design, with components that are smooth and easy to clean, and made of highest-grade materials. Not only do precision dosing systems ensure compliance and safety issues in gummy manufacture but also they can make a very healthy positioning among producers as innovators, and commercially benefit them in the extremely competitive market by way of a higher-grade product that appeals to the health-conscious or quality-seeking audience.

Durability and Maintenance of Gummy Machines

Thus, durability and maintenance ordinarily represent the long-term performance and cost efficiency of gummy machines. High-grade gummy machines are usually made of strong materials–stainless steel for instance–that resist corrosion and wear, thus bearing hygienic importance in food production. Some modern machines, for example, carry modular designs so that parts may be changed out quickly. This has the benefit of minimizing downtime while increasing longevity of the equipment.

Maintenance really affects operational efficiencies; thus, each manufacturing industry would have its maintenance cycle. A preventive maintenance plan of inspection, lubrication of mechanical parts, or calibration of a dosing system can largely prevent any interruptions that may be caused by production. Modern gummy-producing machines feature an automated diagnostic tool to identify a defect before it even begins to affect production. Therefore, given their sophistication, these tools essentially support the maintenance work to be carried out more efficiently, therein reducing the cost and ensuring that lost time for production is minimal.

Technology, having advancements, now support self-cleaning systems that facilitate sanitizing processes. These systems do not only support cleaning but also aid in ensuring compliance with food safety rules. Gummy-makers, considering the aspects of durability and maintenance during the production processes, will be able to achieve highest operational efficiency as well as to ensure product quality, thus being more competitive in the marketplace.

Elevating Your Gummy Production with Advanced Machinery

New Technologies in Gummy Manufacture

In recent years, the gummy manufacturing industry befitting such developments for production; the changes, however, have given more precision, efficiency, and scalability. One such consideration is the setting of depositor machines with adaptive temperature control. These machines ensure that the ingredients are treated at the right temperature, thus preventing crystallization from forming in the texture and consistency of the finished product. And by way of real-time monitoring, manufacturers can detect inconsistencies in production and heating controls and thus prevent the multiplication of further problems and product wastage, thereby outputting the highest rates possible.

Another important technological breakthrough to integrate robotics and automation into the gummy production line. These automated systems mix ingredients, deposit gummies, and package with an immense degree of accuracy and in little time. For example, robotic arms integrated with precision sensors are capable of placing gummies into molds very fast and without any human interference, thus, eliminating contamination and assuring product uniformity.

These systems make production workflows smoother, decrease labor costs and errors, and give manufacturers a competitive edge in a high-demand market.

On the contrary, data-driven things like IoT and AI generally have many applications these days. When machines are IoT-enabled, the manufactures are capable of collecting data in real time and analyzing it on equipment performance, production metrics, and ingredient usage. This data is then used to predict maintenance for the product, to optimize energy consumption, and to maximize the productivity. Market trends can be forecasted with AI systems, which also customize product offers and improve formulation computations synthesizing past recipes and consumer preferences. Such technologies provide gummy producers with excellent managerial tools to sustain operational excellence while adapting rapidly to market evolution.

Auxiliary Equipment Integration for High Output

Another vital role of auxiliary equipment is to optimize the gummy producing industries-that is, extra equipment that goes into enriching production processes. They aid in accuracy, keep up speed, and reduce wastage of raw materials when combined with other complicated equipment such as dosing, cooling tunnels, and unloading machines. For example, automatic dosing machinery delivers counterparts of ingredients-their dosage-to an equal extent and hence directly affects the product’s quality and uniformity. Cooling tunnels maintain optimum-temperature conditions in the gelatinizing process-high temperature being detrimental-to ensure the loss of structural integrity of the gummies and of their texture.

Other than the consumable energy and water, having auxiliary machinery that’s energy efficient will help reduce costs immensely and promote sustainability processes. Auxiliary heavy machinery installed with real-time tracking and IoT-enabled device features will enhance operation efficiency, as manufacturers could monitor performance indices, locate bottlenecks, and even carry out maintenance ahead of time. This auxiliary set-up will support uninterrupted production lines with high-volume output, which then will be scaled and semiflexibly customized to demand in an already very competitive marketplace.

The Role of Cooling and Coating in Gummy Production

Gummy Production: The Significance of Cooling Tunnels

Gummy production tunnels are placed to cool the product to maintain quality and product consistency and to scale up manufacturing. The deposition of gummies must be followed by cooling to set them well and retain their shapes. These operations happen with the cooling tunnel under controlled temperature and humidity. Reduction in setting time is achieved alongside prevention against deformation, hence ensuring that the gummies sap their desired texture and final appearance.

Under advanced cooling tunnels, energy-efficient technologies and modular features may allow the manufacturer to scale up production without compromising quality. In an airflow-optimized system, the tunnels ensure even cooling of products, thereby eliminating texture or flavor discrepancies. Also, in order to be extraordinarily adaptable, the climate sections of the tunnel can be modified to meet different product requirements.

The topic of data-driven monitoring is more oriented towards the enhanced efficiency of modern cooling plants by capturing parameters in real time, like temperature changes and cooling time. Innovations, in general, help waste reduction and better use of energy, besides ever-growing demands from consumers for consistency, compatibility, and sustainability. In a way, modern cooling tunnels will allow gummy manufacturers to brand their products as high quality while remaining competitive in a fast-evolving market.

Gummy Improvement Techniques for Coating

Coating techniques generally enhance the overall quality, texture, and appearance of gummy products. Depending on various product specifications and consumer attributes, the manufacturer would then select from different coating types. One type that is widely applied is oil or wax coating, which prevents the gummies from sticking to one another during packing and storage. This coating must be applied with precision to facilitate a smooth surface and retain the desired chewy quality.

Another coating method involves the application of sugar or sour powder, which renders a pleasant taste and texture combination that can appeal to a broader audience. Equipment improvements now enable the coating to be applied evenly across batches, preventing material wastage. Moreover, the advanced systems would allow manufacturers to control various application parameters, including coating thickness, moisture content, and degree of adhesion.

In recent years, the natural coatings have been undergoing changes to become plant-based or organic due to the ever-increasing need for clean labels and sustainability. These coating methods preserve the originality of the gummy in appearance and texture yet require obedience to consumers stressing health consciousness. With multiple coating methods recently supplemented by newer coating techniques, producers gain in terms of further differentiating their gummies while ensuring quality for consumer satisfaction.

Sugar Sanding and Its Effect on Gummy Texture

Sugar sanding, a finishing procedure typical in gummy preparation, is crucial in altering the texture and taste. The procedure consists of coating gummy surfaces with a fine layer of sugar, which is then expected to provide a crunchy sensation in contrast to a chewy interior. Apart from the sensation, sugar sanding also decreases stickiness by forming a protective barrier, which improves handling and packaging efficiency. It has been reported that consumers generally associate a higher quality and more indulgent image with the texture of fully sugar-coated gummies, making sugar sanding a very prominent tool for gummy producers.

Furthermore, advanced formulations are emerging for the niche target population, such as reduced-sugar or alternative sweetener coatings, aiming to balance health consciousness with the desired textural contrast. Harnessing these developments, gummy-makers can enhance their appeal to a truly diverse consumer base, uniting sheer indulgence with functional efficacy.

Packaging Solutions for Gummy Products

Choosing the Right Packaging Machinery

Different key factors are weighed in the decision of which packaging machine will best suit our gummy products: efficiency and product integrity. The master decision has to be packaging type for individual sachets, pouches, or jars -as each requires a very different type of machinery with very different capabilities. Flexible packing machines are suitable for gummies as they can accommodate any shapes and sizes and ensure the right amount of contents is dispensed. Machinery is also verified for speed and volume capacity to meet production volume and of course quality.

The machinery itself is tested for shelf life and product freshness. The gummies must be hermetically sealed by the machine or by acceptable, moisture-resistant packaging, including aroma-retaining liners. Some of the higher-end machines can be integrated into a system that applies a resealable closure or tamper-evident seal onto the packaging, thus enhancing convenience and confidence. I assure you that all machinery meets food safety and hygiene standards, including actual ease of cleaning and stainless steel construction, to ensure compliance with those regulations.

Lastly, I have a general preference for automations and technology on operations. Most modern packaging machines integrate works of weighers, fillers, and inspection systems to eliminate or in any case reduce human error and maximize manual intervention for other tasks. Machine interfaces that are friendly and are endowed with much automation will augment the level of productivity and reduce any downtime due to maintenance or other means of adjustment. When I weigh these factors carefully, I choose the packaging machine that best serves the production objective, affords operational efficiency, and provides a fine finish to the consumer-ready product.

Trends in Gummy Packaging Methods

Studying the trend of gummy food techniques reveals numerous attempts toward sustainability and eco-friendly packaging alternatives. With environmentally conscious consumers entering the market, packaging solutions are either recyclable or made from organic materials. On this occasion, we have seen innovations such as compostable pouches and even single-material designs – as long as they meet the regulatory criteria and customer expectations for sustainability. This shift, by itself, is one less thing hurting the environment, and it contributes to building a brand image committed to green efforts.

Resealable options have been growing increasingly popular for packaging applications for some years. They keep the products fresh and are user-friendly for the recipients. Depending on the packaging innovations employed, these tamper-proof seals may also host QR codes or fresh indicators, among other things, to further facilitate the user experience. Such packaging makes gummy packs viable and also attractive to the tech- and health-conscious sectors.

Food is a visual experience that has to appeal to consumers through good packaging. The containers are richly decorated with good printing and lay emphasis on minimalism to offer a transparent window into the product, thus attracting more trust with dubiously motivated consumers. Thus, keeping in tandem with these trends in gummy packaging will help ensure innovative, functional, and attractive design-based packaging specifications for the modern-day value-conscious consumer.

Ensuring Shelf Life and Quality through Effective Packaging

The technical evaluation of such matters with a dash of creativity is what I have applied so as to ensure shelf-life and product quality through packaging. Therefore, I can offer packaging solutions that will provide the greatest protection for the product and help in keeping it fresh through the use of advanced packaging materials and technologies. The very nature of barrier packaging is that it should prevent penetration of oxygen and moisture, so that product degradation can simply not occur over time. This way, the product remains protected through the barrier against factors of degradation. This treatment becomes more significant when it comes to gummy products, which are highly sensitive to environmental parameters like temperature and relative humidity.

Maintaining quality through and after distribution must be a foremost consideration in product design, which I have reiterated with these packaging solutions. Resealable closures and tamper-evident seals can keep the product fresh, even after the product is opened for the first time; they thus contribute convenience and peace of mind to the consumer. Along with these, I would also keep desiccant pouches and nitrogen flushing in mind to maintain texture and taste.

By merging innovative solutions with consumer-centric packaging, I can confidently assure that the products arrive at the customer, maintaining their intended quality and shelf life. This said, dedication to excellence fosters customer trust and satisfaction, which, in turn, contributes to brand loyalty in a highly competitive market.

Reference Sources

-

Gummy Manufacturing Process: What Are the 7 Critical Factors – GummyGenix

Discusses critical factors like temperature control, ingredient consistency, and water activity. -

Maintenance Tips for Gummy Manufacturing Equipment – TG Machine

Highlights the importance of maintenance for efficiency, energy consumption, and waste reduction. -

The Best Practices for Using Gummies Manufacturing Machines Effectively – Yinrich

Covers aspects like moisture content, shelf-life stability, and packing integrity for quality assurance. -

A Guide to Gummy Manufacturing Equipment – CandyPros

Explains factors such as material compliance, production line capacity, and temperature control.

Frequently Asked Questions (FAQs)

What is a gummy-making machine, and how does it work?

How do I enhance gummy production with advanced manufacturing equipment?

What else can the commercial gummy machine do?

What type of mold is used in gummy production?

How does automation improve the gummy manufacturing process?

What are the recent developments in gummy production technology?

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.