You have found the correct recipe which produces fluffy biscuits...

Read MoreMaster the Art of Baking with This Guide on How to Use Biscuit Machine Effectively

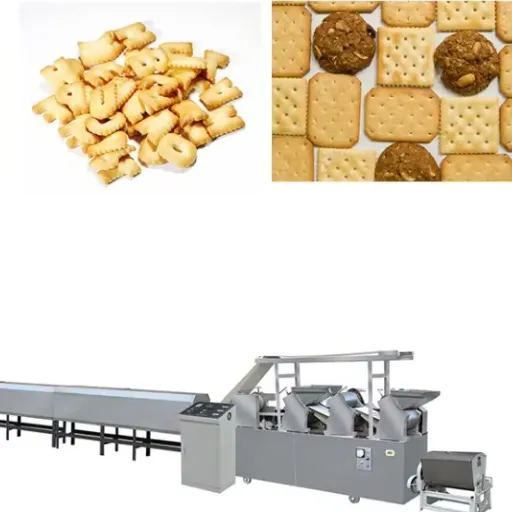

Baking is both an art and a science, with every tool assisting the consummation of a creation through the aid of an individual. One of such tools is the biscuit machine, which is the biggest game-changer that can iron out the difficulties of the process into an efficient and fun activity for any baker that would have previously been laborious. However, the real potential can only be harnessed through learning the effective use of a machine, rather than merely possessing one. This article will take you by the hand through everything you need to know to become proficient in biscuit making: buttery shortbreads, crunchy cookies, or decorative delights. Discover everything from setting up to ensuring your consistency is unparalleled, so your baking can soar to new heights. Ready to have your kitchen labeled as “creative and flavorful”?

Understanding the Biscuit Machine

How A Biscuit Machine Works

Biscuit machines produce or form by extruding the dough through a nozzle or mold of desired shape and size for uniformity and precision. Dough preparation must be consistent to ensure that it flows well inside the machine. Thicker, pressure, and speed adjustments for dough extruders are provided by the modern biscuit machine; hence, bakers adjust output values according to recipe requirements. It is suitable for heavy and large-scale production since it reduces a large amount of manual work and gives less margin for human error in maintaining quality. Alongside this, they also possess a cutting and stamping mechanism to further speed up and open up the creative channels for biscuit design. Knowing how it all works will make sure you retain the output and get consistent results with uniform high-quality biscuits.

Key Features of a Biscuit Maker

| Feature | Description | Benefits |

|---|---|---|

| Automated Functionality | Features automated functions for dough mixing, shaping, and baking | Less manual labor, enhanced productivity |

| Customizable Settings | Adjustable settings for thickness, texture, and shape variations | Easy adaptation to recipe requirements and consumer taste |

| High Production Capacity | Accommodates heavy production schedules with consistent batches | Meet larger scale demand, optimal production efficiency |

| Energy Efficiency | Equipped with energy-saving features | Reduced operational costs, environmentally friendly |

| Hygienic Design | Stainless steel and modular units, easy-to-disassemble parts | Simple cleaning, food safety standards compliance |

| Precision and Consistency | Programmable controls and accurate cutting tools | Uniform size, shape, and quality; consumer trust |

| Digital Integration | IoT systems for remote monitoring and control | Real-time analytics, informed decision-making, proactive troubleshooting |

Key Takeaway: With these novel features, a business gains efficiency, reduces operational expenses, and consistently delivers the best quality to customers.

Picking the Right Biscuit Machine for Your Needs

The ideal biscuit machine requires some forethought to ensure it is appropriately tailored to your production needs. These are the points one should look into:

Production Capacity

Estimation of how many biscuits your firm should produce every day. For a small business, compact machines with limited output will be sufficient; however, large-scale operations require machines with greater capacity to produce thousands of biscuits per hour.

Customization

Modern biscuit machines offer slight customizations, allowing settings to be adjusted for the shapes and sizes of biscuits, as well as minor textural differences. Machines with virtually plug-and-play functionality for their molds and cutters would allow you to change your product line without any downtime.

Material Durability

Chapter machines are constructed with food-grade, rust-resistant stainless steel for enhanced durability, hygiene, and resistance to wear. Higher-quality machines nevertheless prove to be cost-efficient over time, mainly because they require little to no maintenance.

Efficiency and Energy Use

Energy efficiency means lower running costs and a smaller carbon footprint. Modern models feature specially designed motors and heaters that enable the machines to perform efficiently with minimal power consumption.

Automation Features

Such features can reduce manual working steps on the one hand, through semi or full automation; on the other hand, integrated dough feeding, baking control, and cooling systems significantly contribute to productivity and consistency.

Space Requirements

Consider the space you have available in your facility, and make the purchase accordingly. When space is limited, a smaller model naturally becomes the better choice, whereas larger machines with higher capacities require a significant amount of floor space.

Maintenance and Support

Choose a machine that offers straightforward maintenance with easily accessible components for cleaning and repairs. Consider brands that provide excellent customer support, comprehensive warranties, and readily available spare parts.

Costs and ROI

Consider the upfront costs in relation to long-term benefits, such as reduced operational time, decreased waste, and improved product quality. Modern equipment, which generally costs a bit more, can lead to better yields and higher profits in the long run.

These crucial factors will enable companies to find a biscuit machine that aligns with their production goals, budget, and operational level, ensuring a smooth and efficient manufacturing process.

How to Use a Biscuit Machine

Using a Biscuit Machine-Step-by-Step Guide

Step 1: Prepare the Ingredients

Start by gathering the ingredients for your biscuit recipe. Ensure the use of fresh, high-quality ingredients to achieve the best taste and texture. Ingredients have to be weighed with precision, and digital scales and measuring cups are recommended.

Step 2: Set Up the Machine

Position the biscuit machine on a steady, level surface for smooth operation. Verify that all parts are clean and correctly assembled according to the manufacturer’s guidelines. Most modern machines come with easy-to-use settings for customization, allowing you to configure options such as size, shape, and thickness to your preferred specifications for production.

Step 3: Load Dough

Gently load the dough into the hopper or the designated loading area of the machine. Overloading can cause it to work inefficiently and to dispense irregular amounts of dough for the biscuits. Some machines have indicators or alerts to assist you during the loading process.

Step 4: Set the Machine

The next step is to choose settings that correspond to your biscuit type. These options usually include choices for thickness, size, texture, and finishes suitable for baking. Accordingly, a more advanced machine might have built-in modes for specific recipe preparation, saving you the trouble of setting up every time while ensuring good results.

Step 5: Beginning the Process

Turn on the machine and let the biscuit-making process begin. During this time, keep a close eye to ensure everything is in order. Many modern machines possess error-detection capabilities and will alert an operator should anything go wrong.

Step 6: Collector and Transfer

After the biscuits are formed, they are gently collected from the withdrawal place. Care must be taken when handling them to ensure their shape and integrity are retained. Transfer to baking trays or to the next process station as required; in large plants, machines may be integrated into conveyor systems for easy operation.

Step 7: Clean the Machine

After use, always clean the machine to maintain sanitary conditions and prolong its lifespan. Remove the detachable parts for deep cleaning, if possible. Never use abrasive cleaning materials or anything that will mar the finish of the machine. Regular service, of course, will go a long way in ensuring smooth long-term functioning.

Step 8: Understand Production Graphs

Some of the latest biscuit machines can now generate known production graphs, including volume output and time efficiency. Minutely revise these graphs from time to time, so that you can rectify problem areas and use the optimum production output with a minimum of waste.

Success Tip: Working with these process steps will enable the operators of the biscuit machine to produce high-quality products efficiently, facilitate a smooth workflow, and maintain consistency.

Preparation: Ingredients and the Right Tools

Some fancy treats have to be made one way. Biscuit making entails a few essential basic ingredients-that is: all-purpose flour, sugar, baking powder, butter, milk, and eggs. The exact measurement of each ingredient is very crucial to maintain uniformity and quality in every batch of products produced. There are a good number of interesting things that we can do to increase the fragrance, such as vanilla extract, cocoa powder, or spices to diversify the flavor profile as per the type of biscuits.

On the tools side, operators should ensure access to measuring scales, mixing bowls, dough cutters, and rolling pins for pre-machine preparation. Also, biscuit machines should be capable of performing industrial operations with proper mold configurations, temperature-controlled baking ovens, and automated conveyor belts to advertise a smooth process. Appropriate tools and machines must be maintained regularly to prevent interruptions during production. Preparation done right, in fact, sets the workflow right for making superb ware.

| Category | Items | Purpose |

|---|---|---|

| Core Ingredients | Refined Flour | Base structure of biscuits |

| Sugar | Sweetness and texture | |

| Baking Powder | Leavening agent | |

| Butter | Flavor and richness | |

| Milk | Moisture and binding | |

| Eggs | Binding and structure | |

| Essential Tools | Measuring Scales | Precise ingredient measurement |

| Mixing Bowls | Dough preparation | |

| Dough Cutters | Shaping before machine processing | |

| Rolling Pins | Pre-machine dough preparation |

Tips for Operating Your Biscuit Maker

Expert Operating Tips

- Preheat and Test Your Machine: Preheat your biscuit maker to the recommended production temperature as soon as production begins. This would ensure even baking, and there are greater chances of ending up with uneven products and those that are only halfway baked. A test run should be conducted to identify any irregularities in the machine’s operation, using a small quantity of dough, and adjust production settings accordingly.

- Calibrate Dough Thickness: Achieving equal dough thickness is extremely important for producing biscuits of a certain quality. Use adjustable rollers or settings on your machine to ensure precise measurements are maintained. Regular calibration will minimize waste, ensuring that every batch complies with set uniformity standards.

- Monitor baking temperatures: Each biscuit requires its own ideal baking temperature. Make full use of the controls on your oven to ensure that the heat is closely maintained, remembering never to exceed the temperature, as that could affect flavor, texture, and appearance. It is a good idea to buy a good thermometer for double-checking the internal machine temperatures, just in case.

- Regular Cleaning and Maintenance: Cleaning responsibilities begin with keeping all parts of the biscuit maker clean, including molds, rollers, and conveyor belts, following each production run to prevent residue buildup and contamination. Schedule a maintenance interval to assess the machine for wear and tear, which can contribute to improved operational effectiveness and longevity.

- Control Ingredient Ratios: Measuring ingredients accurately contributes much to great quality biscuits. Look into your recipe and make changes according to the flour type, moisture, and working capacity available in your plant. In more advanced types of equipment, such controlling operations are done automatically, dispensing ingredients in exact amounts.

- Production data tracking: Almost all modern biscuit machinery can have data tracking capabilities incorporated therein. Use them to check and track such metrics as batch sizes, processing times, and dough usage. Analyze such data for the bottlenecks, efficiency, and opportunities to enhance the overall production processes.

- Observance of Safety Protocols: Make sure safety precautions are followed at all times. The operators must be trained in the safe operation of the machinery. There should also be other safety features installed, such as emergency stops and safety barriers, which always need to be fittingly engaged before the operator is allowed to work with the machine.

By following these tips, you can maximize the efficiency of the biscuit machine while ensuring the consistent production of high-quality biscuits in every batch.

Making Biscuits with Different Shapes and Sizes

Creative Ways to Shape Your Biscuits

Creativity and innovation are the next things baking has to offer; thus, making every product appealing and unique in its way. Using biscuit-making equipment with adjustable molds, the butter-maker can try anything, from a circle and square to more fun shapes, such as hearts or stars, or even seasonal ones like snowflakes and pumpkins. Interchangeable nozzles allow even more customization, such as detailed patterns and edges, that customers will love.

Custom embossing rolling pins or stamps are used to further personalize the texture on top of your biscuits with textures, logos, or messages, making these products truly unique. Consider size variations as well: miniature-size biscuits for small bites, or giant-size ones for tugs of war—varieties to satisfy all customer preferences and demands.

The data shows that elegant design and good branding attract greater customer engagement and actually help justify premium pricing. Marrying good looks with good taste will certainly make your biscuits the icing on the cake for your target market.

Use Cookie Cutters to Bring Out Unique Designs

Cookie cutters make for well-suited implements to create visually appealing and themed biscuits that speak to your audience. Trying out different shapes and sizes such as geometric designs, seasonal styles, or even custom designs will increase the beauty of your baked goods. An industry trend suggests that on an increasing scale, the market is paying more attention to intricately designed, Instagram-worthy treats that can visually set a product apart in the landscape of competing products.

Little changes in size or icing techniques can attract different kinds of attention or branding for an occasion. For one, embossing cutters in the shape of a logo or a message serve to blend–sometimes very subtly–the brand’s presence with the identity of the cookie without compromising its flavor. Properly positioned and strategically used, these cookies can stir passenger interest and lead to brand loyalty, opening channels for user-created content where users post pictures of such artistic designs on social media.

Play Around with Different Biscuit Sizes

Exploring biscuit sizes and shapes in the culinary field has a huge advantage in presenting an artistic display pleasing to the eye and fulfilling a more straightforward function. This idea of being on the smaller side, just slightly bigger than a bite, makes them very flexible at parties or for samplers since they fit nicely into retain their shape and are easy to prescribe in portions. Bigger ones allow one to indulge their craving just a bit more while offering very bold, oversized designs to steal the spotlight. In line with consumer trends, offering additives like size mixes in a single packaging in the form of gift sets or variety packs might raise a product’s perceived value and so attract broader set audiences. In terms of design, predicates can move away from conventional shapes to something more eccentric, whether they are geometric or thematic, thereby activating a playful or elegant vibe fit for a certain period or campaign, all providing an assisting thrust for identity in serving more customers’ expectations.

Exploring Variations: Butter Cookies and More

How to Make Butter Cookies with a Biscuit Machine

Butter cookie-making is an art that goes through the motions of precision and creativity: that being thinnish and crisp treats, perfectly shaped. Begin with the finest quality dough: soft unsalted butter, granulated sugar, powdered sugar to fine, and all-purpose flour. For aroma, vanilla or almond essence may be used. Beat butter and sugar till light and fluffy. Add dry ingredients in two or three additions, taking care not to overmix. Overmixing results in hard dough that is very difficult to handle.

After preparing the dough, one must take it to the biscuit machine. Such machines usually have interchangeable plates to create more elaborate designs and patterns. Choose a shape plate that corresponds with your theme or occasion, whether it is a casual merry period gathering or a more elegant occasion for tea. The nozzle of the biscuit machine must be pressed onto a baking sheet lined with parchment paper, and the lever or handle should be pressed to dispense the cookie dough. Leave an equal amount of space between each cookie to allow for proper baking.

Bake in the oven for about 10-12 minutes at 350°F (175°C), or just until the edges begin to look a shade of golden. When out of the oven, they need to be cooled on the pan for a few minutes before joining their perfect partners-the wire racks. Perfectly buttery and good-looking, the confectionery would perfectly complement a cup of tea or coffee or can just be devoured on their own. Biscuit machines give a professional result without restricting you from being creative in shape, filling, and flavors that will charm your customers away with treats they will never find anywhere.

Butter Cookie Recipe Quick Reference

Temperature: 350°F (175°C)

Baking Time: 10-12 minutes

Visual Cue: Edges should be slightly golden

Adding Flavors and Ingredients

Seasons can be endlessly made in infinite flavor combinations if an individual so wishes, giving expression and uniqueness to the otherwise very mundane cookie. Few of the conventional classics remain ever-recognized and can almost be assumed to be eternal in their usage. Still, fairly earnest attempts are made to combine more complex pairings of brightness and zest with a good herb like rosemary or thyme that complement those favorites well. From there, on the much sweeter side, there could be anything from chocolate chips, dried fruits, and caramel chunks put in to complement the butter cookie. Matcha fades behind espresso powder or cardamom and saffron could really make down the exotic factor.

Depending on the trader’s dietary wants, substitutions like whole-grain flours, coconut sugar, or their plant-based counterparts may be an option. Added nutrition will be a selling point for adults with an indulgence: things like chia seeds, oats, or flaxseeds. The possibilities are truly endless, thus affording you the opportunity to create innovative recipes that your target market connects with and simply cannot wait to try again.

The Better Biscuit Alternatives

The modern-day biscuit-making needs to be able to put out several flavors as well as health-oriented options complementing a fairly balanced diet of contemporary food requirements. Some natural substitute for refined flour could be almond flour, chickpea flour, or even oat flour, and these go toward enhancing the nutrition in any selection of foods containing protein, fiber, and other important nutrients. On the other hand, natural sweeteners from maple syrup, honey, or date paste will give a sugar touch to the mix but lessen the glycemic load as opposed to pure sugar.

These fats, considered bad, are a no-no for people wishing to keep good health, and so it would be best to cut butter out of biscuit recipes and replace it by way of either avocado, coconut oil, or Greek yogurt-giving the necessary texture and allowing for good heart health. Nuts and seeds, plus the additions of dried fruit, take the recipes down a more complex path of flavor enriched in good vitamins and minerals. Some are said to, among other things, keep blood-sugar levels balanced, improve digestion, and boost energy-giving points for health and indulgence.

Given the growing consciousness about clean eating, such substitutions speak to a more health-informed clientele and encourage home cooks and professionals to bake biscuits for health-conscious consumers. In their versatility, the options demonstrate how biscuit recipes are poised to be revised in response to current dietary preferences, while still leaving room for new creativity at their core.

| Traditional Ingredient | Healthier Alternative | Benefits |

|---|---|---|

| Refined Flour | Almond flour, chickpea flour, oat flour | Higher protein, fiber, and essential nutrients |

| Granulated Sugar | Maple syrup, honey, date paste | Lower glycemic load, natural sweetness |

| Butter | Avocado, coconut oil, Greek yogurt | Heart health promotion, maintained texture |

| Basic Recipe | Add nuts, seeds, dried fruits | Enhanced vitamins, minerals, deeper flavors |

Common Mistakes and Troubleshooting Tips

Identifying Common Biscuit-Making Issues

Perfecting the biscuit can really be tricky, and with every preparation comes a different mishap. Several problems are discussed below along with the minutest tips to avoid trials and obtain consistent excellence:

| Problem | Cause | Solution |

|---|---|---|

| Flat Biscuits | Less leavening, overworking the dough | Use enough leavening (baking powder/soda), avoid over-handling, chill dough before baking |

| Dry or Crumbly Texture | Imbalanced wet/dry ingredients, overbaking | Measure accurately, monitor baking time, add yogurt/cream/buttermilk for moisture |

| Uneven Baking | Temperature variations, inconsistent dough thickness | Check oven thermometer accuracy, roll dough evenly, rotate pans halfway through |

| Lack of Flavor | Under-seasoning, missing complementary ingredients | Add salt, sugar, herbs, cheese, or spices; use fresh, quality ingredients |

| Sticky Dough | Excess moisture, warm dough | Lightly flour work surface and hands (don’t over-flour), chill dough before handling |

When these factors are taken into account, bakers can easily troubleshoot their methods, refining them to yield consistently delicious biscuits that suit any palate. Some tweaks and practice will turn these usual problems into opportunities for developing sculpting skills.

Biscuit Too Much or Too Little Cooking Time

If I get undercooked biscuits, the very first thing I try to consider is how much more baking they still require. If their undercooked condition is so slight that a few more minutes in the oven at the exact temperature will suffice, I will do so, watching them very closely so as not to let them brown. If they are pale and doughy in appearance, I tend to lower the oven temperature and bake them for as long as it takes for the centers to cook without burning the outer layers. I find knowing how to use a thermometer really helpful; with most biscuits, the perfect bake is at a temperature of around 200°F inside.

On the contrary, if I have accidentally overbaked them, resulting in dry and hard biscuits, I know there are many ways to rectify the situation. One thing I can do is to brush melted butter or honey on top right after baking to moisturize and add flavor. If, however, the biscuits had been allowed to cool, then the softer feel could be restored by wrapping them in a wet paper towel and microwaving them for a little while. These overbaked biscuits are very usable for preparing bread pudding or creating crumb toppings, so they certainly need not go to waste.

With experiences, I learned to rely more upon my instincts and baking itself. What really helped was the use of an oven thermometer to verify temperature and a timer so that nothing had to be watched for ever getting overbaked. From the war between underbaking and overbaking, we have become better bakers, and my skills have grown with some alteration of techniques.

Maintenance and Cleaning of Your Biscuit Machine

Keeping my biscuit machine in top shape has been key in ensuring the very consistency of drawing close to results and in extending the lifespan of the equipment. Usually, I would clean it right after washing it down and carrying out some maintenance checks now and then to ensure the performance is not compromised and to prevent any accumulation. Being my thing, I would unplug my biscuit machine right after baking and just let it air-cool. Then, I would wipe the exterior and baking surface down with a clean, soft cloth or sponge that was barely damp: this would rid any crumbs, grease, or residue. If my biscuit machine had some removable parts, like trays or non-stick plates, I would take them out and get them washed by hand in warm, soapy water, ensuring that after that, it is scorhed before putting them into place again.

In the case of stubborn grime or burnt-on residues, I have found that a baking soda and water mixture really works. I moderately apply this paste to the surface and go in with gentle rubbing, with a non-abrasive implement like a silicone spatula or a soft-bristled brush, to keep from scratching the machine. Of course, it is also very important to look at the manual for special cleaning directions, as some parts may not be dishwasher-safe or may require special care. Somewhere like a hinge or a crevice may gather crumbs and needs to be attended to quite thoroughly, getting in with the help of a toothpick or compressed air.

I am another wonderful maintenance worker. I check the machine for signs of wear and tear that might need my attention-those loose screws, cracked components. Would lubrication of moving parts be needed? Then I’ll do it according to warranty: otherwise, I’ll clean the cord and plug, stock it away in a dry, dust-proof place, and forget about it. With a continued routine of doing this, I could wholeheartedly say that I’ve seen the biscuit machine through to reliability, efficiency, and constantly ready for baking perfect biscuits.

Maintenance Checklist

- Unplug machine and allow to cool completely

- Wipe exterior and baking surfaces with damp cloth

- Remove and wash removable components in warm, soapy water

- Use baking soda paste for stubborn grime

- Clean hinges and crevices with toothpick or compressed air

- Inspect for loose screws or damaged components

- Lubricate moving parts as per manufacturer guidelines

- Clean cord and plug

- Store in dry, dust-free location

Reference Sources

- How to Use a Biscuit Machine to Make Biscuits with Different Ingredients and Flavors – Foods Machine

This guide explains the process of preparing dough, loading it into the biscuit machine, and using the feeding system effectively. - Biscuit Machine Connection Tutorial – Bakers Lounge on TikTok

A step-by-step tutorial on connecting and setting up a biscuit machine, ideal for beginners. - The Ultimate Guide to Perfect Biscuit or Cookie Dough – HandyMach

This guide offers expert tips on preparing the perfect dough for biscuit machines, including kneading techniques and optimal flour usage.

Frequently Asked Questions (FAQs)

What is the process of making biscuits with a biscuit-making machine?

Making biscuits with a biscuit-making machine begins with preparing the dough, which is made from simple ingredients such as flour, sugar, and butter. Once the dough is ready, you will feed it into the machine, which will shape it into the intended biscuit sizes. The machine operates at a high speed and pressure, thereby forming the dough into even shapes to ensure each biscuit is uniform. The dough is then removed from the machine and simply placed on baking sheets or trays to be baked to that nice golden color. Following the manufacturer’s instructions will guarantee that your biscuits come out tasty every time.

What are the particular ways I can customize my biscuits on a biscuit machine?

Create a biscuit by experimenting with various ingredients and flavors to generate unique, home-grown treats. Consider adding chocolate chips, nuts, or dried fruits to the ingredients to enhance the taste. Alternatively, you can create larger or smaller biscuits by changing a setting on your biscuit machine and using various attachments for shaping. For sweet biscuits, add a layer of icing or glaze after baking. The biscuit machines themselves offer numerous options to mix and match for various tasty biscuits catering to your palate.

What are the types of biscuit machines available for producing biscuits?

This biscuit machine needs to be cleaned before use. Most biscuit production lines and bakery biscuit-making machines manufacture their own biscuits and have different sets of biscuit-making environments. One makes, for example, a few configurations for producing traditional round biscuits, while other types would be more suitable for making wafers and various types of biscuits. Therefore, the machine required will depend on the quantity to be produced and the type of biscuit you wish to make.

How do you clean your biscuit machine after use?

Cleaning after use helps maintain the machine’s good working life and ensures smooth function. Start by unplugging the machine and removing any removable parts, such as the mixing bowl and conveyor belts. Wash the parts in warm, soapy water using a soft cloth to remove any residual residue from the biscuit dough. Use a cloth dampened with water to clean the body surface of the machine. Abrasive materials should never be used, as they can scratch the machine’s surface. Everything should be adequately dried before reassembling and storing.

How long do the biscuits bake when they are made in a biscuit-making machine?

Since biscuit sizes and machines can vary, the baking time provided is only an approximate estimate. Typically, for smaller biscuits at 350°F (175°C), 10-15 minutes is the recommended cooking time. Still, the biscuits must be observed since the baking time can vary depending on an oven’s capacity or dough thickness. Two recipes rarely have the same baking time, so don’t hesitate to bake a few test biscuits.

Can I use silicone molds with a biscuit machine?

Yes, you may utilize silicone molds with the biscuit machine, especially when making irregularly shaped biscuits. These molds are flexible and non-stick, which makes for easy removal of the baked biscuit. Just ensure your biscuit-making setup is compatible with the silicone molds, allowing you to whip up a variety of delicious biscuits in fun shapes for that extra creative flair in your homemade treats.

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.