You have found the correct recipe which produces fluffy biscuits...

Read MoreThe Ultimate Guide to Ice Cream Biscuit Machine Maintenance and Care

You must clean and repair your ice cream sandwich machine regularly to enjoy it at its best, get more use out of it, and never have any customer or family member be dissatisfied with the treats they love. The idea of having to fix or, worse, replace the machine completely should be a pain point whether you are a dessert shop owner or a dessert-maker at home. More than that, by doing regular servicing of your machine and, thus, saving your time that could be wasted on unexpected breakdowns, you can even cut your running costs. This inclusive guide will pinpoint the ice cream biscuit machine maintenance main points, and through its practical tips, troubleshooting advice, and recommended care strategies, it will leave you with little or no more issues. Ultimately, you will be able to take your machine apart, diagnose the cause of the problem, and reassemble it, working so seamlessly that one can say, “they are the best at creating ice creams that are hard to resist, although they do it with the sandwiches!”

Introduction to Ice Cream Biscuit Machines

What is an Ice Cream Biscuit Machine?

An ice cream sandwich machine and biscuit machine is a special machinery device being designed to put together ice cream sandwich products very carefully and efficiently. Machines are to make the process of ice cream to biscuit/cookie layering very uniform in terms of size, shape, and consistency of every product produced by them. The often-used advanced technologies in such machines include programmable controls, conveyor systems, and customizable settings which also allow the manufacturers to fine tune the production to different recipe requirements and production volumes. These machines are very crucial for businesses that want to produce high-quality ice cream sandwiches in large quantities but still want cost-efficient production of the same.

Types of Ice Cream Biscuit Machines

Ice cream biscuit machines come in a variety of designs and functionalities, tailored to meet the diverse needs of manufacturers. Here are some of the most common types:

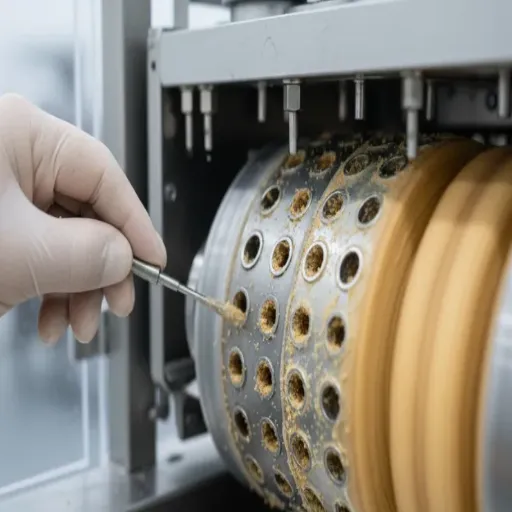

🔄 Rotary Molding Machines

These machines utilize rotary molds to shape biscuits precisely, ensuring uniformity in size and thickness. Rotary molding machines are particularly efficient for large-scale production, offering high-speed output while maintaining consistent quality.

✂️ Wire-Cut Machines

Ideal for creating more intricate biscuit designs, wire-cut machines use a cutting wire to shape soft dough into distinct patterns. These machines are versatile and can handle different dough consistencies, perfect for specialty ice cream biscuit products.

🎯 Stamp Press Machines

Equipped with stamping plates, these machines press dough into pre-designed shapes, creating biscuits with unique imprints or textures. Stamp press machines are often used for distinctive branding or decorative aesthetics on the biscuits.

⚙️ Hybrid Machines

Combining functionalities like molding, cutting, and stamping in a single unit, hybrid machines provide flexibility and efficiency. They are particularly useful for manufacturers seeking to produce a variety of biscuit styles while optimizing floor space and costs.

🏭 Automated Production Lines

These systems integrate several processes, from dough mixing to baking and cooling. Fully automated production lines are designed for high-volume manufacturing and come equipped with advanced controls to streamline operations and reduce manual intervention.

🎨 Customizable Machines

Many manufacturers offer customizable ice cream biscuit machines to cater to specific requirements, such as unique biscuit shapes or tailored production speeds. These machines are ideal for businesses looking to innovate their product offerings.

By leveraging these different types of ice cream biscuit machines, manufacturers can optimize their production processes, meet customer demands for variety, and maintain a consistent standard of quality.

Benefits of Using an Ice Cream Biscuit Machine

✨ Key Advantages

Enhanced Efficiency

Ice cream biscuit machines streamline the production process by automating tasks like shaping, filling, and sealing. This eliminates the need for manual labor and significantly reduces production time, allowing businesses to meet high-demand orders with ease.

Consistent Quality

With precise control mechanisms, these machines ensure uniformity in biscuit size, shape, and thickness. This consistency enhances the overall quality of the final product, helping businesses build trust and loyalty among their customers.

Customization Options

Modern machines offer customizable settings for creating unique biscuit designs or accommodating specific customer requirements. This enables manufacturers to cater to diverse market trends and offer exclusive products that stand out from competitors.

Cost-Effectiveness

By automating key processes, manufacturers can decrease labor costs and minimize waste during production. This leads to higher profitability over time, making the machines a cost-effective investment.

Improved Hygiene Standards

Ice cream biscuit machines are designed with food-grade materials and advanced sanitation features. This ensures compliance with strict food safety standards, reducing the risk of contamination and improving product shelf life.

Scalability

These machines are suitable for businesses of all sizes, from small startups to large-scale manufacturers. Their production capacity can often be adjusted to match the specific needs of the business, making them a versatile solution as demand grows.

By incorporating these benefits into their operations, businesses can effectively optimize productivity, reduce costs, and deliver superior products to their consumers.

Understanding the Production Process

How Ice Cream Cones are Made

Manufacturing of ice cream cones is a beautiful mixture of culinary skills and high-tech devices that are made to produce a very consistent and good quality cone in large numbers. The first step of the process is the making of the batter made from flour, sugar, water, and sometimes other ingredients like oil or flavor that are added to make it tastier. The batter is made and then it is poured into a special kind of machine that is used for making the cones.

After the batter has been mixed thoroughly, it is then poured evenly onto hot plates inside the machine. The batter is then baked to perfection. The time and temperature at this stage are strictly managed so that each cone has the same texture and color. When the cones get baked, the rolled, or shaped, crispy but flexible thin sheets of batter immediately acquire the familiar cone shape while still warm, using either automatic rollers or molds.

The icecream cones are put through a cooling process to make them solid, and quality check is done to make sure there are no cracks or differences. when cones are finally cooled, they are put into the trays carefully and putting them in wraps. Modern technology in cone production along with omitted details in stones, hawk-mouth slices and consequently the shape and texture of these market-aligned needs. The manufacturing process of ice-cream cones is going on the right path of the combination of metallurgy and food-processing excellence in developing designs that control consumer preferences.

Role of Biscuit Machines in Ice Cream Production

Ice cream cones are produced in the most modern production condition where biscuit machines play a very important role in efficiently, consistently, and producing consistent high-quality output that suits consumer preferences. Machines made in detail with each and every part of the cone-making process managed by the machine like mixing, molding, baking, and cooling. Biscuit machines using automation have been keeping the manual workload at zero for both it and technical aspects, such as temperature, thickness, and texture, which also very much maintain their precise control. Lately, biscuit machine technology has been providing such features as programmable settings, so manufacturers can, through this feature, not only from the market but also from the machines produce cones which meet the requirements of various marketing such as different shapes, sizes, designs, etc. Besides, the sustainability measures also help the produced energy to be the best used with the least waste and it would be associated with the environmentally conscious consumer market positively. The last aspect of the case, with precision engineering combined with leading innovations, the ice cream cone and the public’s experience are taken to a level and a half.

Variations: Waffle Cones vs. Biscuit Cups

Ice cream lovers find it easier to enjoy waffle cones because they present a different kind of tasting and serving experience when compared with biscuit cups. Waffle cones are familiar to people by their crunchy texture and their shading, and are the majority of the time produced by a batter that contains sugar and vanilla giving them a rich aroma. Besides being able to carry various scoops of ice cream, they give the eater a satisfying crunch with each bite. The waffle cone’s shape also plays a role as they let desserts be built in layers and make them attractive for the people.

However, biscuit cups represent versatility and portion control. They are made from a harder dough that has a slightly less intense flavor profile, which allows the taste of the ice cream to come through. Biscuit cups are perfect for mess-free, convenient situations like family gatherings or take-out orders. In addition to being just right for ice cream, the form and strength of biscuit cups would make creative serving possible with soft desserts, such as mousses and fruit salads. Both serve as evidence for the cutting edge in biscuit machinery’s innovation and adaptability, which in turn ensures that producers’ machinery can meet individual customers’ different preferences and at the same time provide an elevated ice cream experience.

📊 Comparison: Waffle Cones vs. Biscuit Cups

| Feature | Waffle Cones | Biscuit Cups |

|---|---|---|

| Texture | Crisp and crunchy | Firm and sturdy |

| Flavor Profile | Rich, aromatic (sugar & vanilla) | Mild, lets ice cream shine |

| Capacity | Multiple scoops | Portion control focused |

| Best For | Indulgent, layered desserts | Family events, grab-and-go |

| Design | Ridged pattern | Smooth cup shape |

| Versatility | Ice cream focused | Multiple dessert types |

Maintenance Tips for Your Biscuit Machine

Regular Cleaning Procedures

Having the best performance and long life of your cookie baking machine is very much dependent on creating a systematic clean-up plan and presence of mind for the process. Start with the total disassembly of the removable parts just as the manufacturer has directed so that you can be sure that there are no hard-to-reach places that you have not cleaned. Employ food-grade cleaning agents to the machine and through that to the areas of high build-up such as the batter nozzles and conveyor belts. Residuals should be the most important to be considered which is because the marinated clutter will affect the overall output and the machine’s performance.

When you have cleaned, dip every component of the machine carefully in lukewarm water to get every trace of soap off it. Then, let them dry in the air totally before putting them back together. More so, scrutinize gaskets, valves and electrical parts for wear traces or dirt that can hinder the proper functioning of the machine. But don’t forget the oiling processes which are crucial to the shootout in the reduction of any mechanism. By following these general procedures in Maintenance, you will not only be able to increase the efficiency of your cookie machine but you will also be able to meet the sanitation standards.

Common Issues and Troubleshooting

Proper maintenance and understanding of potential issues are crucial for ensuring the longevity and efficiency of your biscuit machine. Below are some commonly encountered problems, their causes, and solutions to keep your operations running smoothly.

⚠️ Irregular Dough Consistency

Cause: Uneven mixing, incorrect ingredient proportions, or inadequate mixing times.

Solution: Verify ingredient measurements and adjust mixing times as needed. Regularly clean and inspect mixing paddles and bowls to avoid residue buildup affecting uniformity.

🔧 Jamming or Stoppage During Operation

Cause: Residual dough accumulation, worn components, or misaligned mechanisms may lead to blockages.

Solution: Remove and clean all equipment parts regularly. Inspect for damage or signs of wear on mechanical components, and promptly replace as needed.

🌡️ Overheating

Cause: Blocked ventilation, overworked motors, or lack of lubrication in moving parts.

Solution: Ensure ventilation grids are kept clear and unobstructed. Allow cooling breaks during continuous production and apply lubrication to reduce mechanical stress.

📐 Biscuit Shape Deformation

Cause: Misaligned molds, incorrect dough consistency, or uneven pressure during shaping.

Solution: Adjust the positioning of molds and calibrate shaping mechanisms. Test dough consistency prior to large-scale production.

⚡ Electrical Malfunctions

Cause: Loose wiring, defective switches, or insufficient power supply.

Solution: Regularly inspect all electrical connections and switches. If needed, consult a certified technician to address power or wiring issues promptly.

By proactively identifying these issues and applying these troubleshooting techniques, you can significantly reduce downtime while optimizing the performance of your machine. Combining these best practices with routine updates and professional servicing will ensure sustained productivity and consistent quality results.

When to Seek Professional Help

🔍 Professional Service Indicators

There are occasions when the problems at hand are not fully resolved by regular maintenance and troubleshooting. If the problems remain and are strange noises, poor performance, or system errors which are repeating in nature and beyond the capacities of the basic troubleshooting, it is always best to seek a professional’s help. Moreover, when the machine either needs sophisticated diagnostic tools, calibration, or even some repair works with complex electrical or mechanical parts, a professional technician will be the right person to ensure safety and efficiency in the execution of the process. Letting professionals handle intricate repairs implies that you will not only be protecting your equipment’s life expectancy but also be exposing the least risk of poor adjustments, hence attaining the best performance and reliability in the long run.

Improving the Quality of Ice Cream Biscuits

Choosing the Right Ingredients

The very heart of making fabulous ice cream sandwiches lies in the selection of best quality ingredients. Production of a rich and creamy base is easily reached with the help of premium dairy products, such as fresh cream, or milk. Moreover, natural sweeteners like organic cane sugar or honey can be utilized in the perfect combination to bring the best of both worlds. Biscuits that are tender, crumbly, and with the right taste could be achieved by selecting finest quality flours and fats, such as unsalted butter, which give a greater taste to the product. Usage of real vanilla extract, cocoa powder, or fruit purees flavors can add more depth and varieties, but still, preserving the original taste of the products. You may not know it but, feeding guests with the most natural and freshest components will always come with an added edge of the ever-present and understandable top taste and tandem texture effect.

Optimizing Machine Settings for Quality Output

If one wishes to have a uniform and regular output, the orientation of the machine should be set according to the specific requirement of the product to do. The first thing to be done is to fix the temperature controls in such a way that the heat is distributed evenly, something that is a must for baked goods since it can prevent the inside from being either undercooked or the outside being over-browned. The next step is to control dough elasticity, air incorporation in the of the oven, batter heating, or similar aspect by setting blending speeds and times properly. On the other hand, the proper alignment and good condition of machine parts will make a power loss but also human errors and equipment breakdown. At the same time, the utilization of modern monitoring tools helps in providing real-time feedback, thus enabling very quick adjustments that improve product reliability and quality concurrently during production. By going over and refining machine settings continually, one can serve such an excellent and impeccable result that complies with the strictest criteria of quality.

Maintaining Consistency in Biscuit Production

Unparalleled biscuit production consistency can only be achieved by using advanced methods and tools. The introduction of automation process control systems is done in order to apply the use of precisely detailed specifications in the making of every batch thus reducing the variability of the product. For the dough preparation and baking, the moisture analyzers and temperature sensors are the advanced equipment to be used that can keep an eye on the changing conditions which are then corrected by the system itself. In addition, the training of the staff on the new operations and the upgrading of the quality culture are also the ways of increasing the possibilities of no- or least probability of any fault. These are all ways of making processes wrong-free, lead-time short and by this the output, which are the biscuits, will be having one texture, one taste, and one look that are always appreciated by the end-users.

Conclusion: Ensuring Longevity and Efficiency

Recap of Maintenance Best Practices

A consistent focus on exhaustive strategies and adaptive practices is necessary to keep the production process efficient and of high quality. In my opinion, it is important to inspect and calibrate the equipment on a regular basis. This makes the equipment run without any interruptions, which in turn, reduces the cost and time for replacement. Furthermore, the cleaning routine may not only be a preventive measure for the tools’ lifespan but also a way to meet the food, drug, and cosmetic act compliant cleanliness levels. At the plant or site of production, the real-time performance metrics provide valuable feedback for identifying the most critical areas to improve. Butathoning the metrics and addressing mechanical issues proactively contribute greatly to the ease of maintaining both high productivity and product competitiveness.

I also highly prioritize staff training as a critical practice in my operation. In the light of it, when I am looking for my employees to be updated with the latest operational protocols and proficient in the usage of the advanced tools and technologies they come to the aid of the company. Besides, establishing freer communication among the team members will also contribute to the whole process of feedback on processes and hence, the resulting suggestions will be nothing but improvements. Moreover, the use of data analytics to monitor the changes and deficiencies and then to narrow down the workflows and maintainings through schedules is a good way to predict when the problems will occur. Insum, through these practices, one may establish a groundwork for great operational achievements over a long period and maintain the culture of customer expectations satisfaction.

Future Trends in Ice Cream Biscuit Production

The outlook on ice-cream-cookie manufacturing in the future very much emphasizes the responsiveness to consumer needs. The plant-based and dairy-free alternatives sector is such a large and primary driver that it is worth emphasizing. Almost everyone is now talking about it. Tough as that might be, consumers are mostly benefiting from the situation through the availability of these foods. The demand for such products is high among those who have many dietary restrictions including those going gluten free. Vegan milk made from oat, almond or coconut mixed with vegan biscuits still is a knock-out combination. High protein ingredients and, also, natural sweeteners such as stevia and monk fruits are getting prescribed within many quarters of the society and the world of ice cream biscuits.

Sustainability is becoming more and more crucial in the industry. One can easily predict the ongoing success of the eco-friendly methods. it gives the examples likes the switch to sustainable packaging solutions and the use of methods for carbon-neutral production. Even if the topics used in this discussion were of simpler nature like, for example, wrappers that 100% disappear by rotting and the audio of the podcast being from a studio run by someone who also runs a farm, there are to be far-reaching and profound effects of the focus on sustainability if one considers not only the global aspect but also the consumers issue. Soon everyone will be an environment enthusiast and people who care about sustainability will dominate the market.

The highest concentration of sensory input and experience enhancement can be realized through technology. The advanced techniques and the innovations in the texture area lead to a taste that is rich in several layers and at the same time allows for a biscuit that is exceedingly crispy and yet perfectly harmonious which all in all leads to a greater satisfaction. The leading trend is the personalization of ice cream and biscuit combinations in the near future—people will be able to create their own by mixing any flavors and textures on digital platforms. In the case of ice cream biscuit production, the fusion of these three factors, namely health, sustainability, and personalization, is likely to capture more and more of the mass market share while still being very innovative.

Final Thoughts on Choosing the Right Machine

In my opinion, the decision to select the ideal machine for ice cream biscuit production should be a blend of high efficiency, innovation, and adaptability rather than going with any one of them. The production technology’s latest developments have made it possible to use machines that not only make the process faster but also the most customized products and the most sustainable practices. Machines with capabilities such as partly interchangeable parts, automatic flavor injecting, and very accurate temperature adjustment not only make the production process easier but also make it more adaptable to the changing consumer demands.

I, for one, would give preference to a machine that combines top-notch automation with design-your-own options. This way, you can count on the quality being the same all the time yet you can be as creative as you wish—whether you want to put different textures of the biscuits on or to come up with entirely new flavors for the ice cream. Moreover, the energy-efficient machines are clearly the ones to be chosen, given the worldwide drive towards environmentally friendly practices and the continuous escalation of energy prices. The key to cost-saving and the winning over of the consumer who goes for the green products are two main aspects that go hand in hand.

In the end, a correct machine will not only enhance your current production capabilities but also ensure the future viability of your business. By keeping abreast of technological breakthroughs and examining devices in terms of particular business requirements, like the production volume, maintenance needs, and market trends, your selection is guaranteed to be a source of lasting value and a means of distinguishing your brand in a cutthroat industry.

📚 Reference Sources

❓ Frequently Asked Questions (FAQs)

What is an ice cream biscuit machine?

The ice cream sandwich machine is an advanced device that produces perfect ice cream sandwiches, which are a tasty mixture of ice cream and a biscuit. Usually, this machine is equipped with waffle-cone-making features so that the user can prepare various forms of ice cream containment such as cones and cups. Many of the machines come with the choice of fully automated and semi-automatic, which makes production both for home and industrial purposes more efficient. The device often has a temperature control system as a basic design which ensures that the ice cream almost always stays at the right consistency when the biscuit is being made. Also, there are machines that range from gelato to fried ice cream in terms of recipes. Your dessert menu can be expanded greatly with the purchase of a good ice cream biscuits and cones machine.

How does an ice cream cone making machine work?

A machine that makes ice cream cones works by blending the ingredients to create a batter, which is then formed into cones. The whole procedure generally consists of the batter being heated up and increased in size thus being able to take on its characteristic shape. Most of these machines have an interface that is very user-friendly, and they are equipped with a hopper that has the capacity to be loaded with ingredients easily and quickly. These machines are very versatile and can make either hollow waffle cones or solid biscuit cones, depending on the formula. Many of them are also equipped to control the temperature in order to keep the baking conditions at their best. These machines are perfect for the large-scale production of cones since they can handle producing between 50 to 60 units in an hour timeframe.

What are the benefits of using a biscuit making machine?

A biscuit making machine provides a variety of benefits, mainly to those who need to make ice cream biscuits in a fast and easy way. The entire process is optimized by these machines, which means from mixing the ingredients to the depositing operation, the biscuits are sure to be of the desired shape. Apart from being operated automatically and having a large capacity, they are also time-saving and labor cost reducing. Furthermore, some can also be customized, so the users have the chance to try with different tastes and textures. In addition, to producing the biscuits for ice cream, a modern biscuit making machine is usually provided with the necessary equipment for the production of the ice cream itself, therefore assuring the compatibility with the ice cream tastes. To sum up, it wouldn’t be a waste of money to buy the biscuit making machine since the product quality is ameliorated and the in production, the rate and capacity are increased by the machine as well.

What types of ice cream cones can be made with a cone maker?

An ice cream cone maker is able to provide a large selection of different types of cones, such as the traditional waffle cones, sugar cones, and biscuit cones. These machines are highly versatile with the possibility of using different batters and achieving unique textures and flavors. Some of the cone machines are specially built for producing wafer cones whereas others can form more complicated shapes such as the biscuit waffle cone. Also, the creation of cones with different sizes and, therefore, for different serving options is possible in the case when the right ice cream cone machine setup is used. The fact that cone makers are easy to operate and effective is the reason they are greatly needed by ice cream stores that want to supply a range of products.

Can I make ice cream biscuits in a commercial ice cream setting?

Certainly, one can effectively produce ice cream biscuits in a commercial ice cream establishment that employs a separate ice cream biscuit machine. Such ice cream biscuit makers are specifically built for the high volume of business yet they still ensure the quality is preserved so they are a good choice for the busy ice cream parlors. One can trail and error with the different recipes starting from the gelato and to the soft serve variations, to cater to various customer preferences. The innovation of ice cream and biscuit is a new presentation that will have the desired effect on the whole menu. Also, if the machines are automatic making the products, the whole process will be much faster and thus the customers will be satisfied within a short time. This is one capability that is inevitable in places where there is a lot of traffic.

What features should I look for in a high-quality ice cream biscuit machine?

If you are looking for the best ice cream cone maker, you should pay the most attention to temperature control, the complexity of the usage, and the potential for production. With a machine that has a temperature control unit, you can be sure that the ice cream will keep its intended texture for the entire process of baking cones. Go for the models that allow both automatic and semi-automatic operation so that there is the possibility of switching between the two while in the production phase. Be aware of large capacity machines because they could easily be a solution for a commercial biscuit production issue, not only the quantity of the production but also hygiene because the device will need to be cleaned very often. Last but not least, take into account that the machine is backed by all the necessary auxiliary equipment such as a cone maker or tray machine, so the whole process of the ice cream production is smooth.

Are there any maintenance tips for an ice cream cone machine?

In order for ice cream cone machine to work well it has to be maintained. Proper sanitation is highly recommended as left-over ingredients can change the quality of the cones you produce. What you should do is take the machine apart, right after usage, and then wash each piece thoroughly with warm water and soap. Remember to look at the area where the hopper is and the molds as residue can be all over. Besides, the temperature and well as other controls should be checked on a short-term basis electronically. Breaking in of the machine through the movement parts has to be done as well as the manufacturer’s guidelines for the machine are to be followed. If you take good care of your machine, it will work smoothly just like the first time and will not make you wait or come out with cones of low quality.

What types of ice cream can be paired with biscuit cones?

When it comes to ice cream cones, there is a very wide range of options in terms of ice cream flavors that you can pair the cones with, and by doing that you can only increase the overall dessert experience. The choices that are usually picked are the primary ones like vanilla, chocolate, and strawberry, but even pistachio, salted caramel, or gelato can be used for a once in a life time combination. The biscuit cone’s texture is great because it can be aligned to both kinds of ice creams, creamy or crunchy, thus it could be seen as a very flexible choice. You have to go for it in case you would like the ice cream low in fat and sugar, but still creamy and so on.

Related Posts

Blog Categories

Popular Blog Tags

Shanghai Fude Machinery Manufacturing Co., Ltd is a leading manufacturer of top-notch gummy and cookie making machines with more than 15 years’ experience in the industry. We provide creative equipment that ensures accuracy and speed while sharing intelligence with food producers. Shanghai Fude remains to be one of the most reliable companies for food machinery because of its dedication to perfection.